An electrolytic anode plate and its preparation method and application

A technology for anode plates and substrates, which is applied in the fields of material chemistry and environmental electrochemistry, can solve the problems of many electrolytic anode plate coatings, low electrochemical activity of coatings, and poor coating coverage, etc., and achieves low preparation costs, Excellent catalytic activity, beneficial to decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

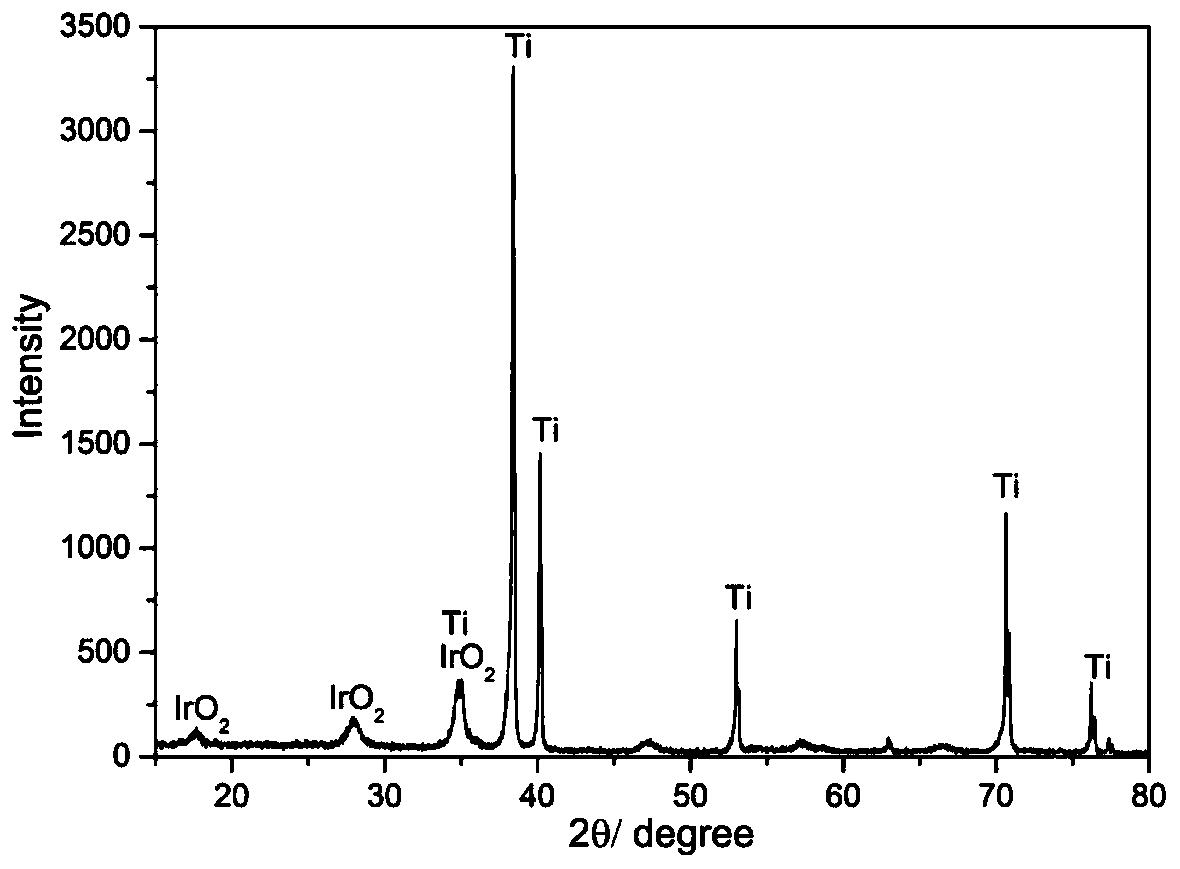

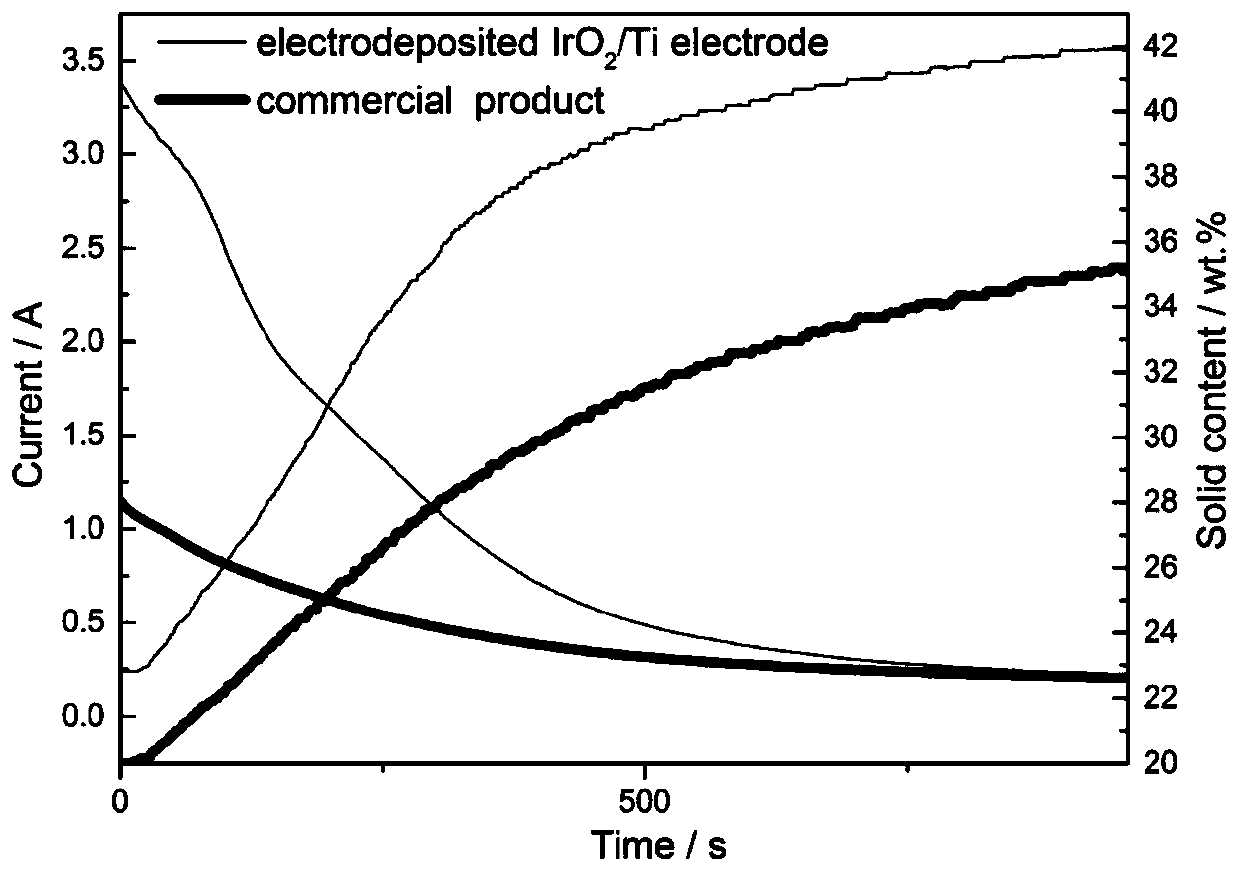

[0042] A kind of IrO suitable for electrolytic dehydration, electrolyzed water and power-to-gas devices 2 -The preparation method of the Sn / Ti anode plate, the middle layer of the anode plate is doped with cheap metal tin, the electrode has excellent catalytic activity and long service life, and the cost is reduced.

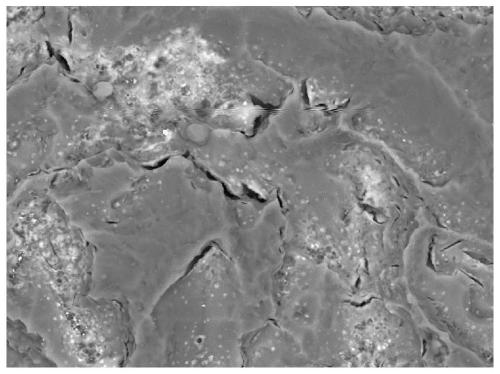

[0043] By adopting the method of direct electrochemical deposition, after coating the intermediate layer on the pretreated titanium plate, the electrode is obtained by direct electroplating. Described method specifically comprises the steps:

[0044] (1) The metal titanium plate with a purity greater than 99.0% is saturated with K 2 CO 3 The solution was soaked for 10 minutes, polished with metallographic sandpaper, soaked and etched in 10wt% boiled oxalic acid solution for 2 hours.

[0045] (2) Prepare H 2 IrCl 6 and SnCl 4 The mixed intermediate layer coating solution with a ratio of 1:1 is dissolved and mixed by ultrasonic vibration, and left to stand fo...

Embodiment 2

[0060] A kind of IrO suitable for electrolytic dehydration, electrolyzed water and power-to-gas devices 2 - The Sn / Ti electrode is prepared by electrodeposition, the intermediate layer is doped with cheap metals, and while the cost is reduced, the electrode has both excellent catalytic activity and long service life.

[0061] By adopting the method of direct electrochemical deposition, after coating the intermediate layer on the pretreated titanium plate, the electrode is obtained by direct electroplating. Described method specifically comprises the steps:

[0062] (1) The metal titanium plate with a purity greater than 99.0% is saturated with K 2 CO 3 The solution was soaked for 10 minutes, polished with metallographic sandpaper, soaked and etched in 10wt% boiled oxalic acid solution for 2 hours.

[0063] (2) Prepare H 2 IrCl 6 and SnCl 4 The mixed intermediate layer coating solution with a ratio of 1:1 is dissolved and mixed by ultrasonic vibration, and left to stand f...

Embodiment 3

[0078] A kind of IrO suitable for electrolytic dehydration, electrolyzed water and power-to-gas devices 2 - The Sn / Ti electrode is prepared by electrodeposition, the intermediate layer is doped with cheap metals, and while the cost is reduced, the electrode has both excellent catalytic activity and long service life.

[0079] By adopting the method of direct electrochemical deposition, after coating the intermediate layer on the pretreated titanium plate, the electrode is obtained by direct electroplating. Described method specifically comprises the steps:

[0080] (1) The metal titanium plate with a purity greater than 99.0% is saturated with K 2 CO 3 The solution was soaked for 10 minutes, polished with metallographic sandpaper, soaked and etched in 10wt% boiled oxalic acid solution for 2 hours.

[0081] (2) Prepare H 2 IrCl 6 and SnCl 4 The mixed intermediate layer coating solution with a ratio of 1:2 is dissolved and mixed by ultrasonic vibration, and left to stand f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com