Vanadium dioxide composite film and preparation method thereof

A vanadium dioxide and composite thin film technology, which is applied in the direction of superimposed layer plating, vacuum evaporation plating, coating, etc., can solve the problem of the decrease of the solar light regulation performance of the film, the reduction of the infrared light regulation performance of the film, and the near-infrared transmittance. Problems such as rising, achieving the effect of being suitable for large-area application, fast and stable large-area preparation, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] For the preparation of the functional layer, after the second protective anti-reflection layer is deposited, it can be directly sputter-deposited on the surface of the second protective anti-reflection layer, and then heat-treated at the same time. Alternatively, after the deposition of the second protective anti-reflection layer and the heat treatment are completed, the sputtering deposition of the functional layer can be performed, and finally a heat treatment process can be performed to complete the preparation.

[0056] As mentioned above, control the background vacuum to be higher than 5×10 -4 Pa. The purity of argon and oxygen used is above 99.9%.

[0057] In the present invention, the thin film deposition process is carried out at room temperature, which is relatively low in the preparation of vanadium dioxide thin film by magnetron sputtering, which is beneficial to improving energy utilization rate and reducing heat energy consumption. At the same time, the h...

Embodiment 1

[0065] Choose ordinary white glass as the base and cut it into a suitable size for later use;

[0066] Substrate cleaning: Rinse the substrate in deionized water, then ultrasonically clean the substrate with absolute ethanol for 10 minutes, dry it with a high-purity nitrogen gun, place it in the sample chamber, and fix it with high-temperature tape. Vacuuming: Use a mechanical pump and a molecular pump to evacuate the sample chamber and the sputtering deposition chamber. Sputtering deposition: Pass the mixed gas of argon and oxygen into the sputtering deposition chamber, control the total gas pressure at 1.0Pa, the ratio of oxygen partial pressure at about 40%, adopt intermediate frequency power supply, control the power supply current at 5A, and the power is optimal 2.0kw, using high-purity tungsten as the sputtering target, for sputtering deposition, the deposition time is 5min, and the first layer of WO is obtained 2.9 (x=0.1) Protect the AR coating layer. Then, adjust th...

Embodiment 2

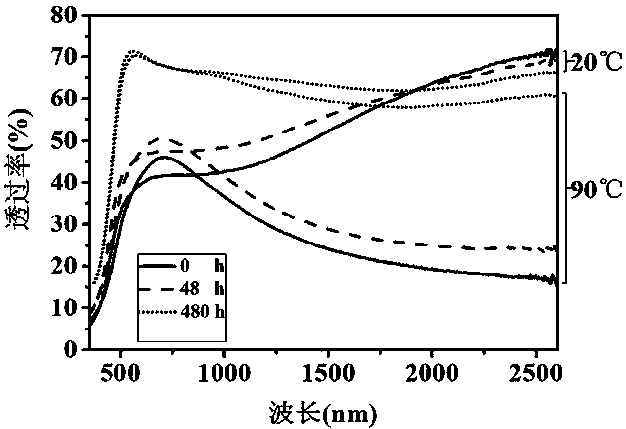

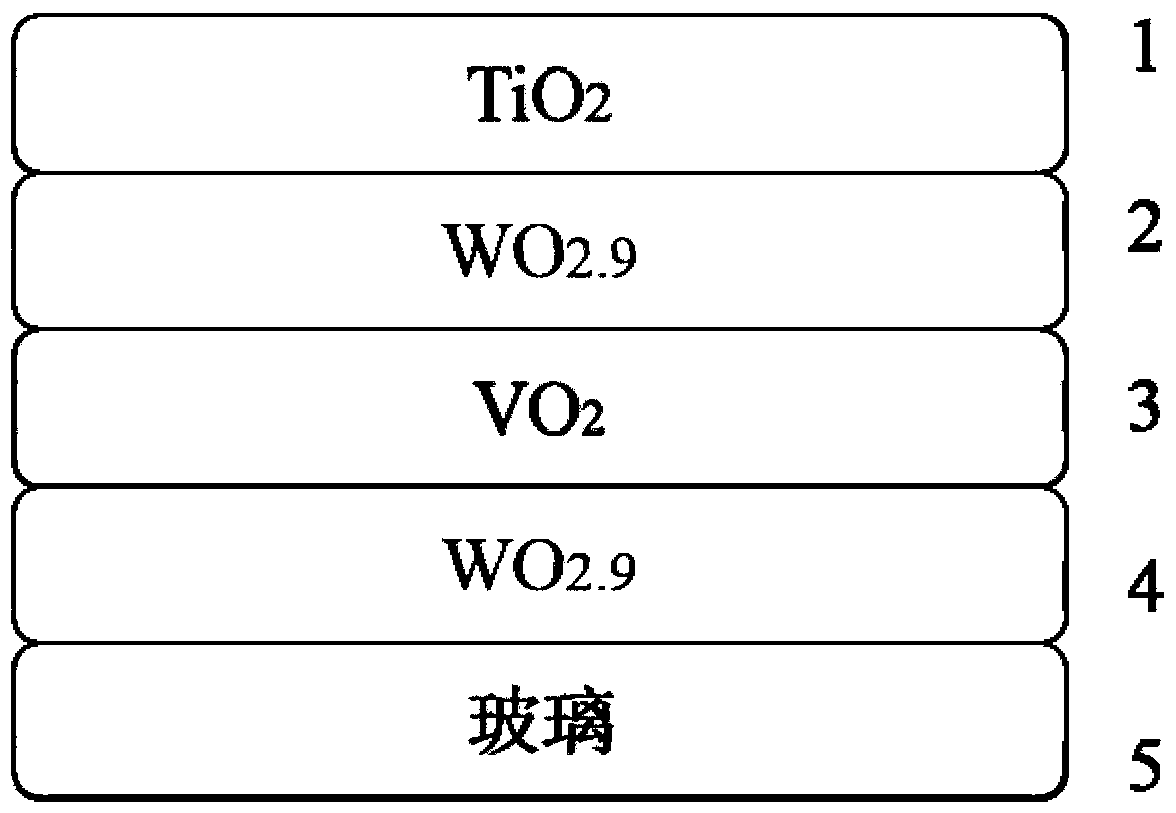

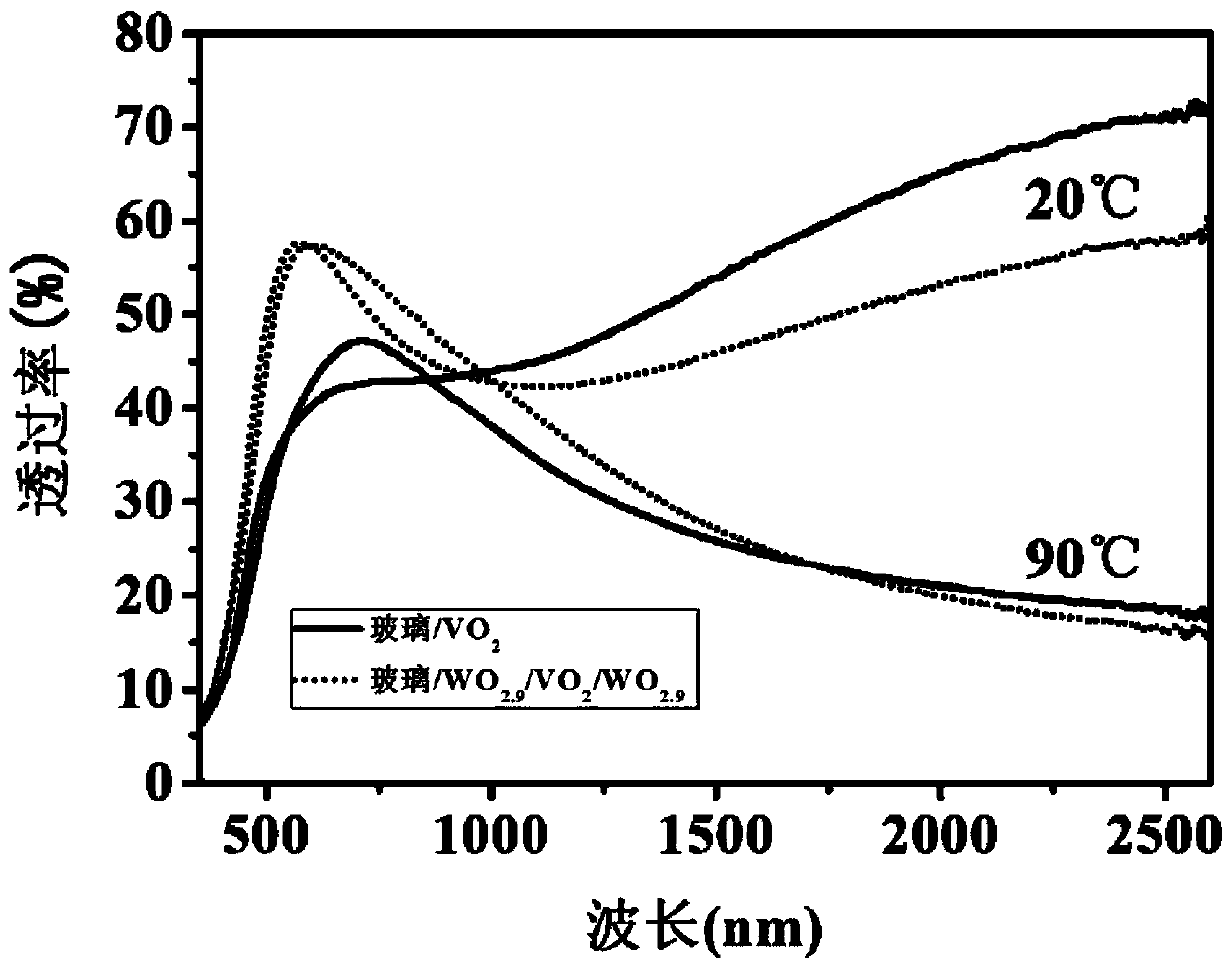

[0069] As described in Example 1, on the basis of completing Example 1, control the partial pressure of oxygen to 40%, keep the total working pressure constant, use an intermediate frequency power supply, control the power supply current to 5A, and the power is preferably 2kw, using high-purity tungsten As the sputtering target, on the unannealed substrate / WO 2.9 / VO 2 Sputtering deposition on the composite thin film, the deposition time is 5min. Using the annealing process in Example 1, finally obtain the substrate (glass) / WO 2.9 / VO 2 / WO 2.9 Composite film (see image 3 center right). The thickness of the second protective anti-reflection layer was measured to be 45nm by scanning electron microscope section observation. The characterization of the thermal hysteresis loop at a fixed infrared wavelength shows that the substrate / WO prepared in this example 2.9 / VO 2 / WO 2.9 The phase transition temperature of the composite film is 54°C.

[0070] Using an infrared-vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com