Preparation method and application of catalyst PdGaX/Ga2O3 catalyst used for selective hydrogenation of acetylene

A catalyst and selective technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of low ethylene selectivity and high price of palladium, and achieve the goal of preparation The method is simple, the performance is excellent, and the effect of selectivity is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

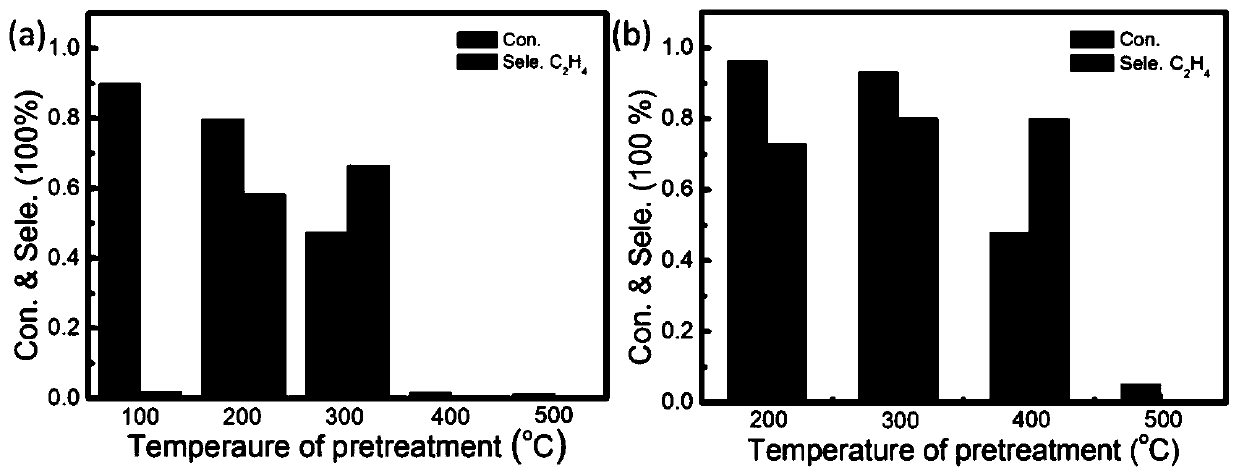

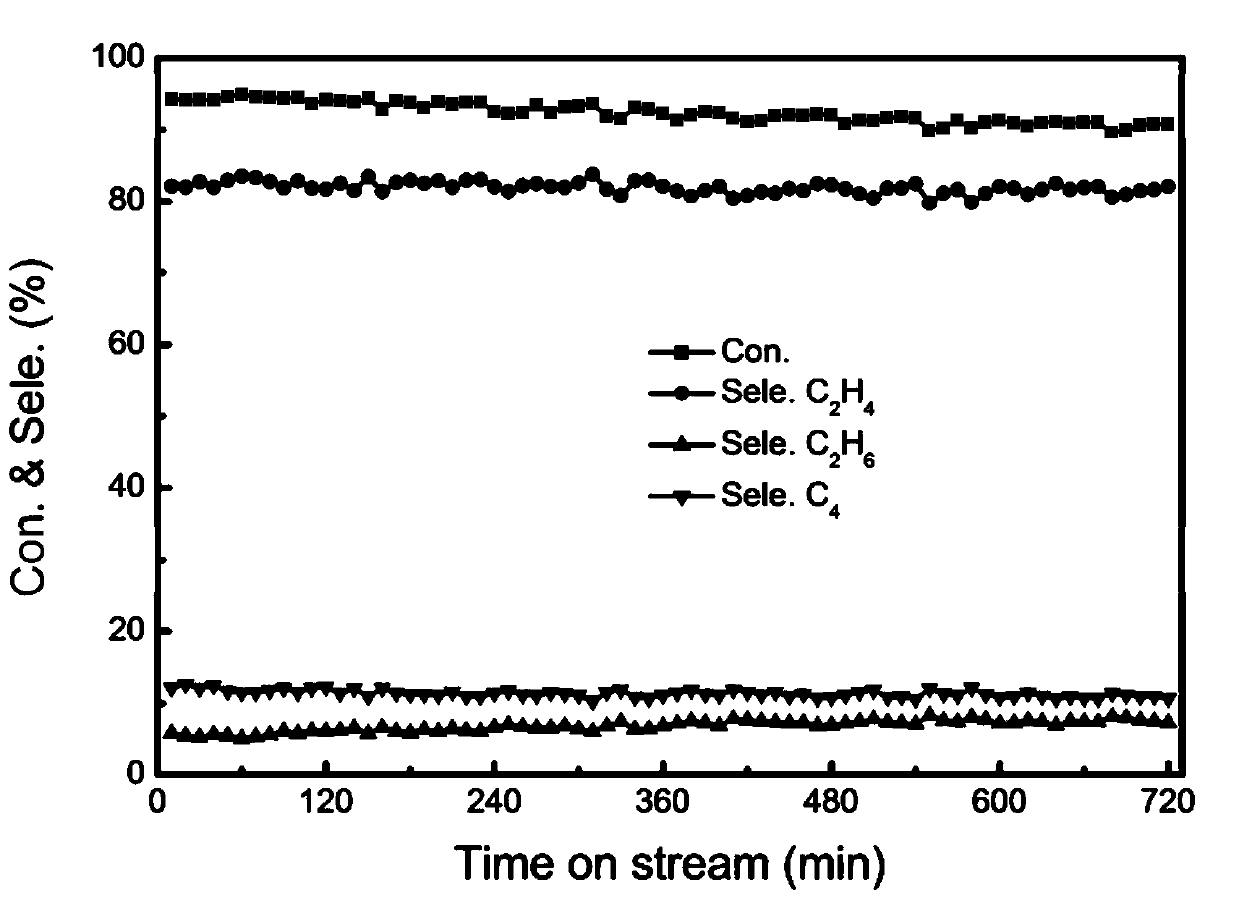

[0031] This embodiment prepares PdGa X / Ga 2 o 3 The catalyst process is as follows:

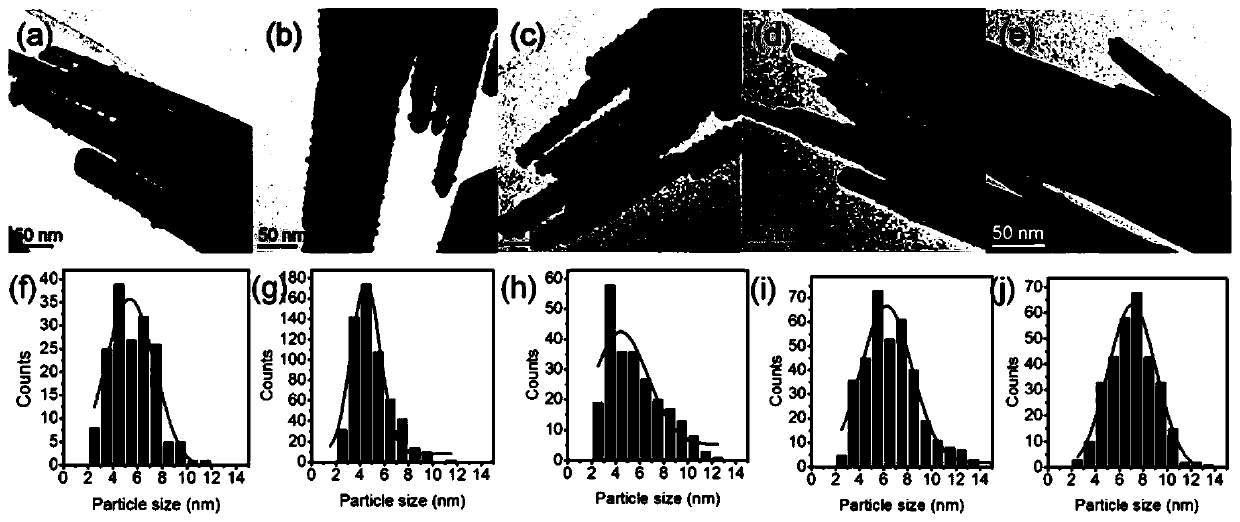

[0032] 1. Synthesis and preparation of Ga by hydrothermal method 2 o 3For the nanorod carrier, dissolve sodium dodecylbenzenesulfonate in water, and stir vigorously until the mixture is uniform. Gallium nitrate hydrate was added thereto under stirring condition, the solution became cloudy, and after stirring for a period of time, large flocs appeared. Afterwards, sodium hydroxide solution (0.1 mol / L) was added dropwise to the mixed solution to adjust the pH to 8 to obtain a flocculent colloidal solution. Put the colloid solution in a closed container at 140°C for more than 8 hours by hydrothermal method. Centrifuge, wash with water to get white powder, after calcination at 500℃, get Ga 2 o 3 The nanorod carrier, the gallium oxide nanorod carrier has a diameter of 20-100 nm, and the gallium oxide nano-particles in the catalyst have a particle diameter of 4-10 nm.

[0033] 2. Immersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com