Brown coal resin for drilling fluid and production technology of brown coal resin

A lignite resin and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced drilling fluid use efficiency, ineffective fluid loss control, poor thermal stability, etc., to achieve fluid loss reduction Salt resistance, improved fluid loss performance, and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

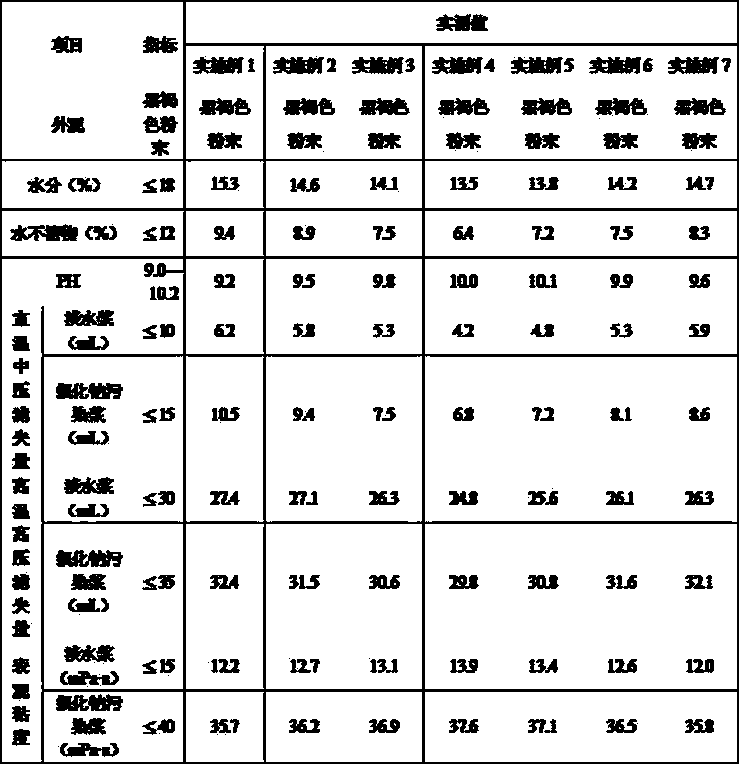

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of a kind of lignite resin for drilling fluid

[0028] (1) Accurately weigh each raw material component according to the formula: lignite 10 kg, sulfonated phenolic resin 10 kg, alkalizing agent 2 kg, sulfonating agent 2 kg, sulfonated phenolic humic acid 2 kg, carboxymethyl cellulose 1 kg, 3 kg of sodium sulfomethyl humate, 4 kg of acrylamide polymer, 12 kg of trimethylamine, and 20 kg of water, weighed and placed in corresponding containers for later use; alkalizing agents are potassium hydroxide, hydrogen Any one of sodium oxide; the sulfonating agent is any one of sodium sulfite, sodium metasulfate, sodium pyrosulfite, sodium sulfate, sodium metabisulfite, sodium bisulfite, and sodium bisulfate; the acrylamide polymer is polyacrylamide , cationic polyacrylamide or partially hydrolyzed polyacrylamide;

[0029] (2) Use a mechanical pump to pour the weighed water into the reaction kettle, start the stirring device to stir; in the continuous s...

Embodiment 2

[0033] Embodiment 2: Preparation of a kind of lignite resin for drilling fluid

[0034] (1) Accurately weigh each raw material component according to the formula: lignite 15 kg, sulfonated phenolic resin 15 kg, alkalizing agent 5 kg, sulfonating agent 5 kg, sulfonated phenolic humic acid 4 kg, carboxymethyl cellulose 3 kg, 5 kg of sodium sulfomethyl humate, 6 kg of acrylamide polymer, 15 kg of trimethylamine, and 22 kg of water, weighed and placed in corresponding containers for later use; alkalizing agents are potassium hydroxide, hydrogen Any one of sodium oxide; the sulfonating agent is any one of sodium sulfite, sodium metasulfate, sodium pyrosulfite, sodium sulfate, sodium metabisulfite, sodium bisulfite, and sodium bisulfate; the acrylamide polymer is polyacrylamide , cationic polyacrylamide or partially hydrolyzed polyacrylamide;

[0035] (2) Use a mechanical pump to pour the weighed water into the reaction kettle, start the stirring device to stir; in the continuous s...

Embodiment 3

[0039] Embodiment 3: Preparation of a kind of lignite resin for drilling fluid

[0040] (1) Accurately weigh each raw material component according to the formula: lignite 18 kg, sulfonated phenolic resin 18 kg, alkalizing agent 8 kg, sulfonating agent 8 kg, sulfonated phenolic humic acid 5 kg, carboxymethyl cellulose 5 kg, 7 kg of sodium sulfomethyl humate, 7.5 kg of acrylamide polymer, 18 kg of trimethylamine, and 24 kg of water, which were weighed and placed in corresponding containers for later use; alkalizing agents were potassium hydroxide, Any one of sodium hydroxide; the sulfonating agent is any one of sodium sulfite, sodium metasulfate, sodium pyrosulfite, sodium sulfate, sodium metabisulfite, sodium bisulfite, and sodium bisulfate; the acrylamide polymer is polypropylene Any one of amide, cationic polyacrylamide or partially hydrolyzed polyacrylamide;

[0041] (2) Use a mechanical pump to pour the weighed water into the reaction kettle, start the stirring device to sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com