Method for simulated moving bed adsorption separation of p-xylene in C8 aromatic hydrocarbon

A technology for simulating moving bed and carbon octane aromatics, which is applied in the field of isomers, can solve the problems of poor separation effect and achieve the effect of improving the efficiency of adsorption and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

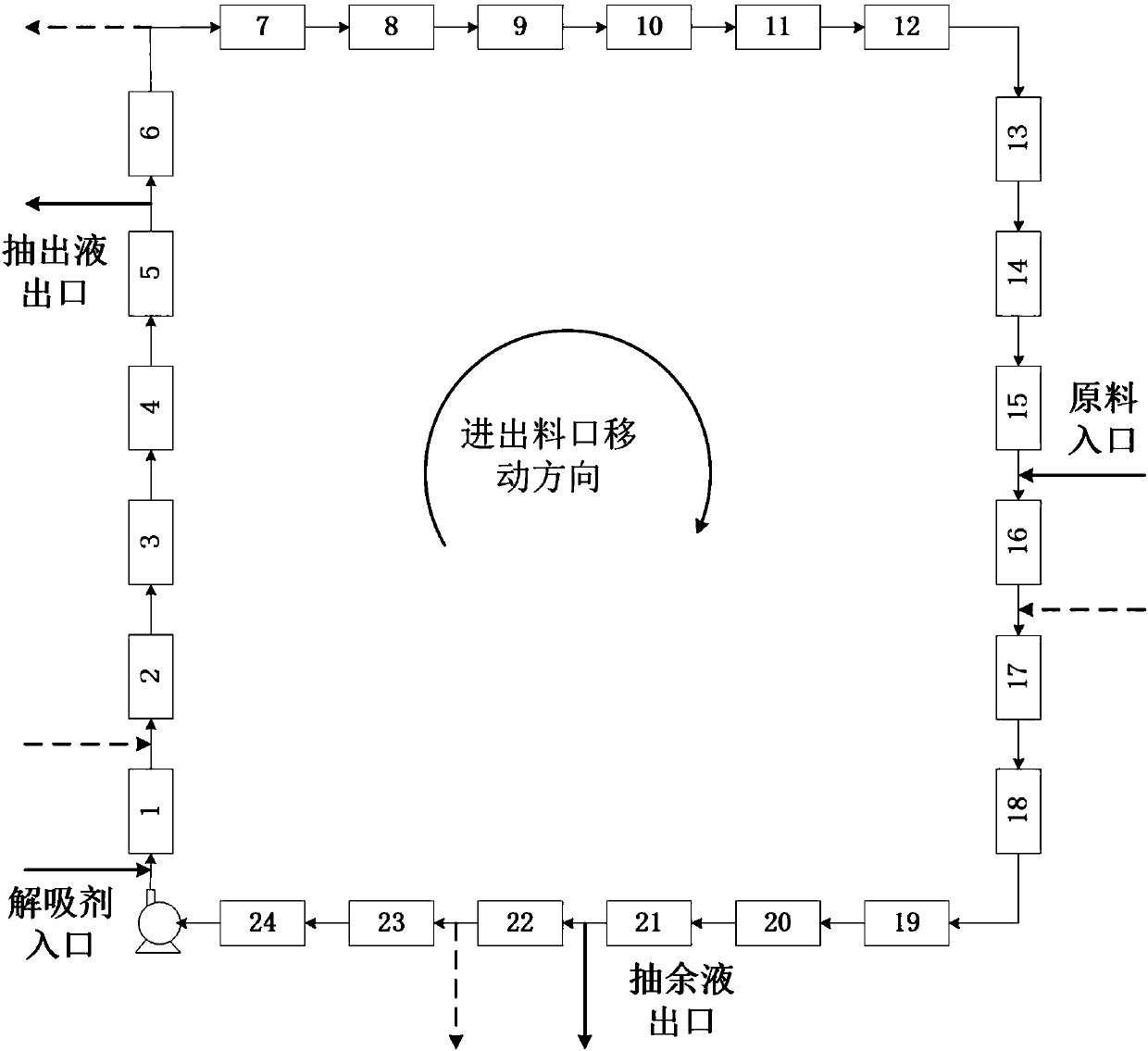

Method used

Image

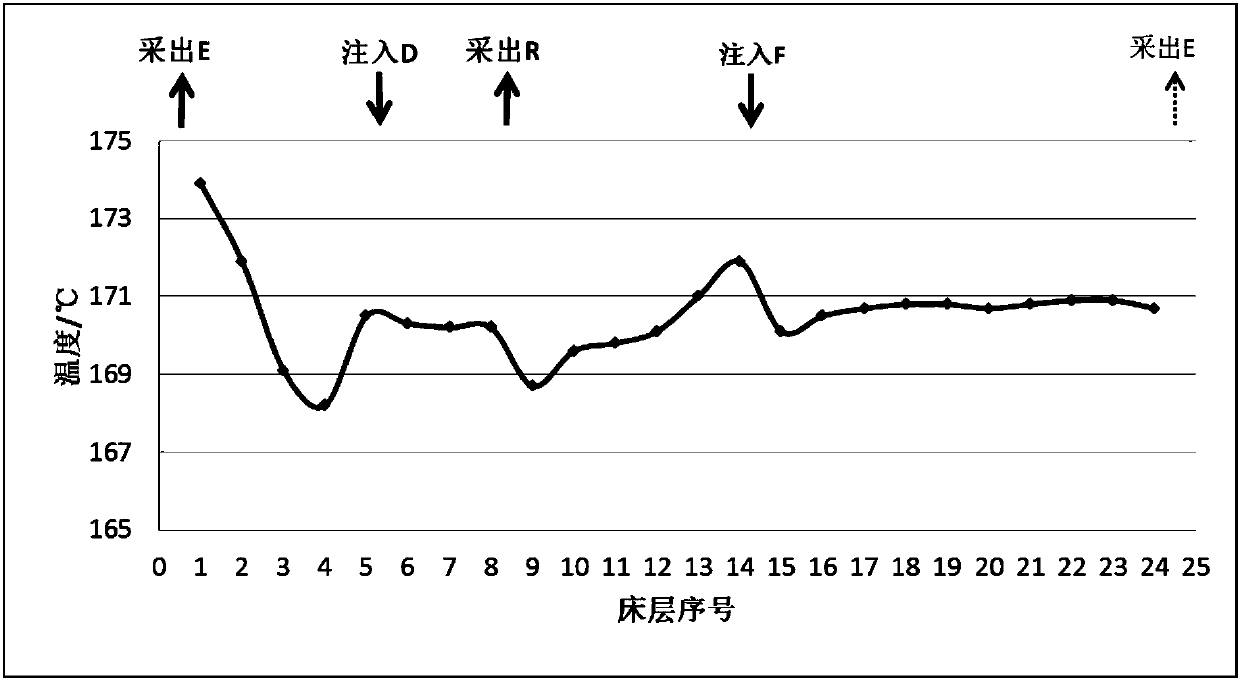

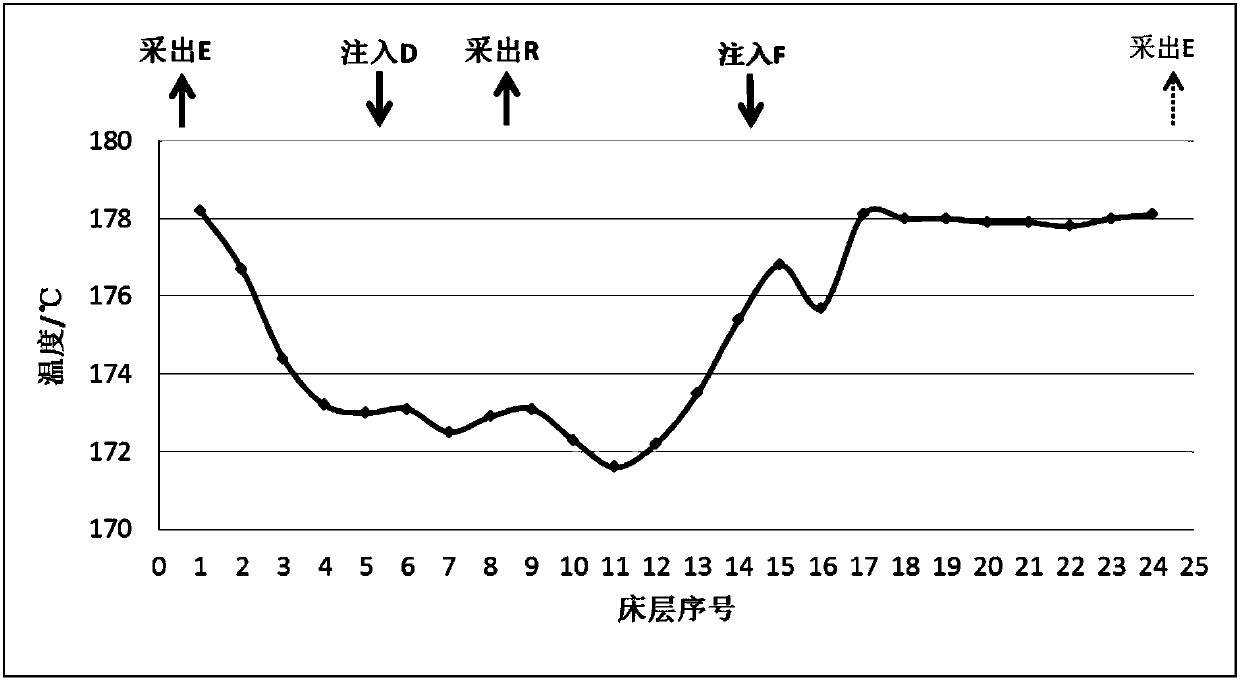

Examples

preparation example Construction

[0022] The preparation method of the above adsorbent is as follows: the NaX zeolite is mixed with the binder, and then rolled and calcined to obtain matrix pellets. The ion exchange is carried out with the compound solution containing barium and / or potassium, and the adsorbent is obtained after the exchanged solid is dried and activated. The potassium and barium-containing compounds are preferably potassium and barium nitrates or chlorides. When preparing the adsorbent with BaKX zeolite as the active component, the matrix pellets can be contacted with the barium-containing compound solution for Ba ion exchange, and then contacted with the potassium-containing compound solution for K ion exchange, and then dried and activated. The calcination temperature is preferably 480-560°C, and the drying temperature is preferably 90-130°C.

[0023] The desorbent used in the adsorption and separation process of the method of the invention is p-diethylbenzene, the boiling point of which is...

example 1

[0032] Preparation of adsorbents for liquid phase adsorption separation.

[0033] The NaX zeolite with a silica / alumina molar ratio of 2.4 was mixed with kaolin in a mass ratio of 92:8, rolled into a ball, and calcined at 520°C for 6 hours. Carry out ion exchange, the liquid / solid volume ratio of solution and adsorbent is 10, the concentration of barium nitrate solution is 0.3mol / L, and the exchange degree calculated according to the residual sodium content after exchange is 95mol%. After the exchange, the solid was dried at 100° C. for 3 hours, and activated at 220° C. for 2 hours to obtain adsorbent A, in which the BaX content was 93.41 mass % and the kaolin content was 6.59 mass %.

example 2

[0035] The NaX zeolite with a silica / alumina molar ratio of 2.4 was mixed with kaolin in a mass ratio of 92:8, rolled into a ball, and calcined at 520°C for 6 hours. For ion exchange, the liquid / solid volume ratio of the solution to the adsorbent is 10, and the concentration of the barium nitrate solution is 0.3 mol / L. Get the solid after Ba ion exchange and carry out ion exchange with the solution of potassium chloride, the concentration of potassium chloride is 0.5mol / L, and the liquid / solid volume ratio of the solution and the adsorbent is 2, calculated according to the residual sodium content after the exchange The degree of exchange was 95 mol%. After the exchange, the solid was dried at 100°C for 3 hours and activated at 220°C for 2 hours to obtain adsorbent B, wherein the BaKX content was 93.1 mass%, the kaolin content was 6.9 mass%, and the molar ratio of K to Ba in BaKX zeolite was 0.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com