Lead-free ferroelectric photochromic material based on rare earth doping and preparation method and application thereof

An electro-optical and ferroelectric technology, applied in the application of photochromic materials, the field of preparation of ferroelectric photochromic materials, can solve problems such as difficult real-time control of materials, and achieve low cost, good physical and chemical stability, anti- Good effect on fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

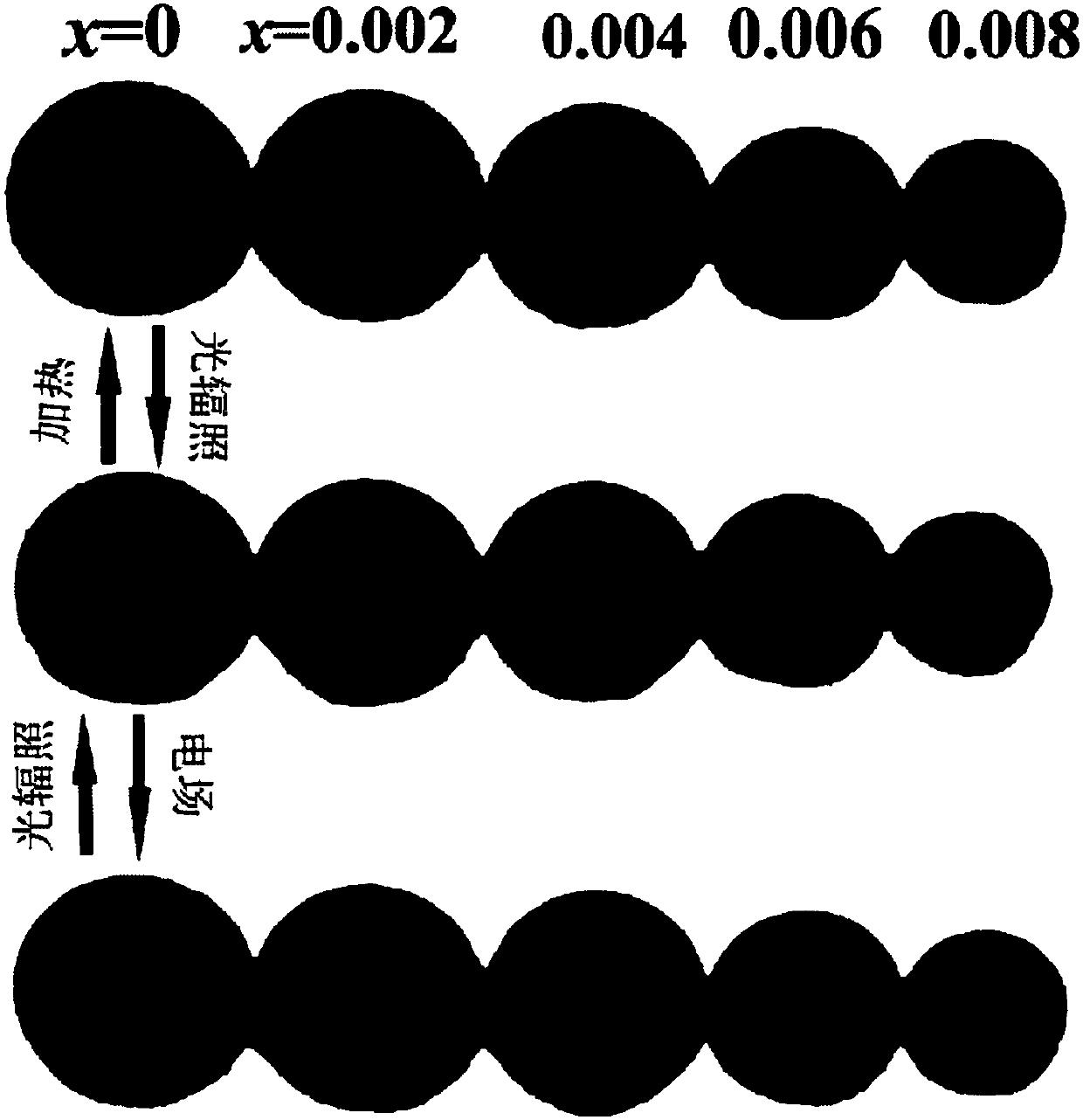

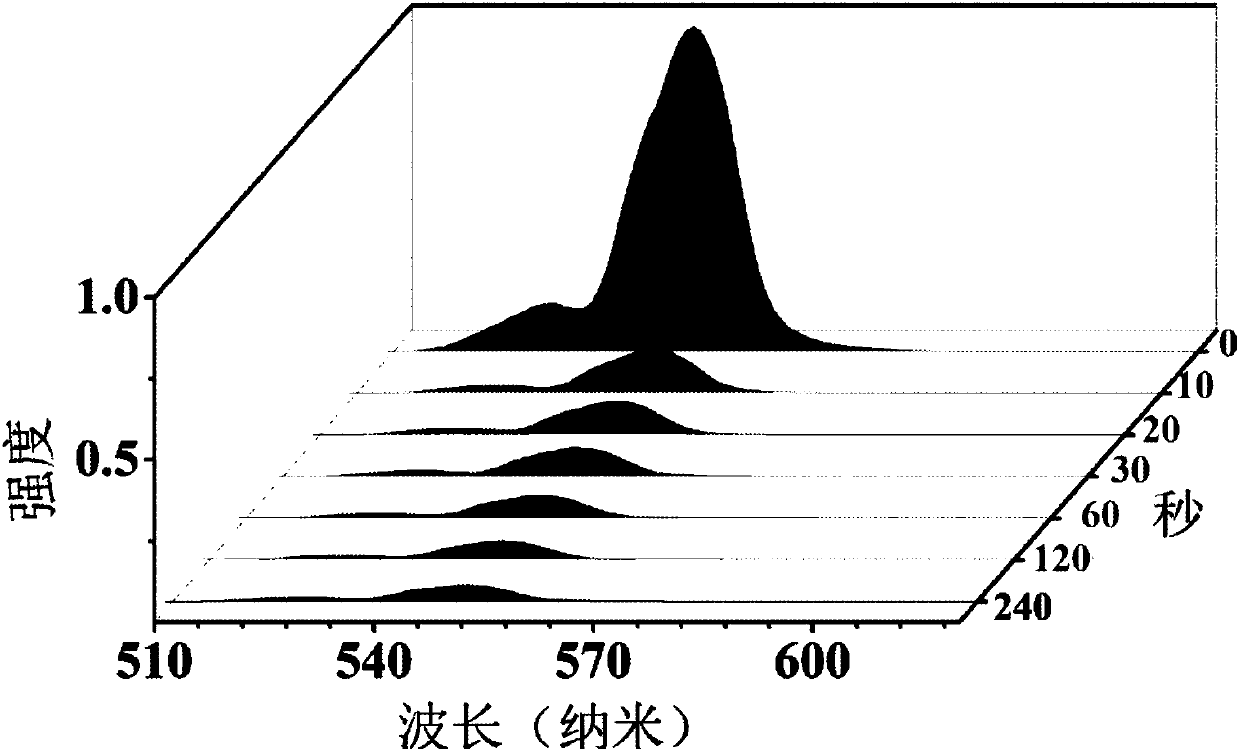

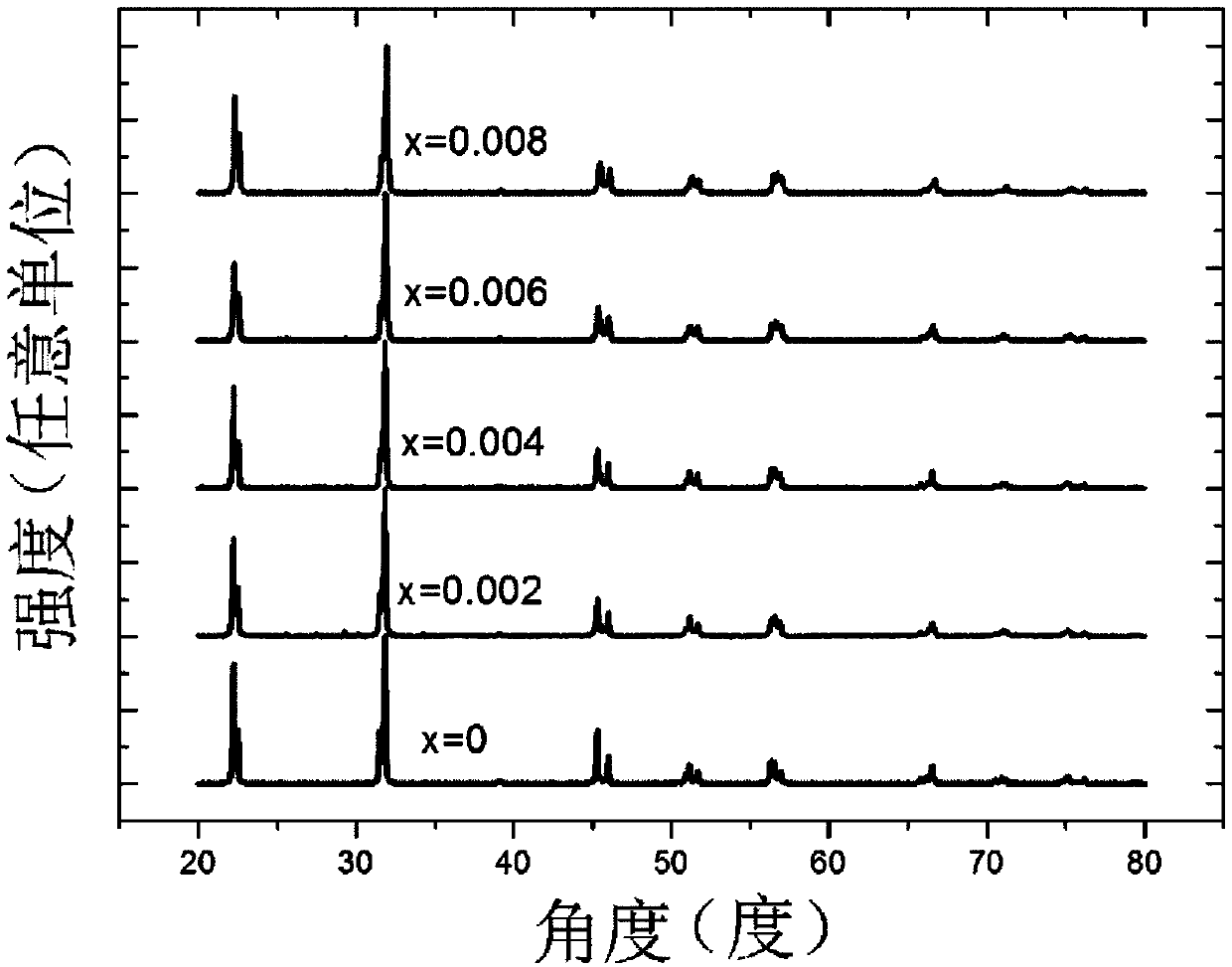

[0022] Using 99.8% pure Na 2 CO 3 , 99.8% Na 2 CO 3 , 99.8% TiO 2 , 99.9% Er 2 o 3 and 99.9% Yb 2 o 3 As a raw material, according to the chemical formula (K 0.5 Na 0.5 ) 0.998-x Er 0.002 Yb x NbO 3(x=0.002, 0.004, 0.006, 0.008) are weighed separately, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of raw materials, agate ball volume, and ball milling medium absolute ethanol is approximately equal to 1:1 : 1.5, it was ball milled for 8 hours, and the raw material after ball milling was put into an oven and baked at 80° C. for 4 hours. Afterwards, the dried raw material is pressed into a raw material body with a diameter of 40mm by a tablet machine at 100Mpa, and then the pressed body is put into a KBF1400 box furnace for pre-firing, and the pre-firing condition is 600°C for 3 hours. Decompose the binder, then keep the temperature at 1050°C for 4 hours, crush the pre-fired block sample, grind it into powder, sieve i...

Embodiment 2

[0024] Using 99.8% pure Na 2 CO 3 , 99.8% Na 2 CO 3 , 99.8% TiO 2 , 99.9% Er 2 o 3 and 99.9% Yb 2 o 3 As raw material, according to the chemical formula (K 0.5 Na 0.5 ) 0.998-x Er 0.002 Yb x NbO 3 (x=0.002, 0.004, 0.006, 0.008) are weighed separately, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of raw material, agate ball volume, and ball milling medium absolute ethanol is approximately equal to 1:1.2 : 1, it was ball milled for 10 hours, and the raw material after ball milling was put into an oven and baked at 80° C. for 3 hours. After that, the dried raw materials are pressed into a raw material body with a diameter of 40mm by a tablet machine at 200Mpa, and then the pressed body is put into a KBF1400 box furnace for pre-burning, and the pre-fired condition is 700°C for 0.5 hours. Decompose the binder, then keep the temperature at 1200°C for 2 hours, crush the pre-fired block sample, grind it into powder, siev...

Embodiment 3

[0026] Using 99.8% pure Na 2 CO 3 , 99.8% Na 2 CO 3 , 99.8% TiO 2 , 99.9% Er 2 o 3 and 99.9% Yb 2 o 3 As raw material, according to the chemical formula (K 0.5 Na 0.5 ) 0.998-x Er 0.002 Yb x NbO 3 (x=0.002, 0.004, 0.006, 0.008) are weighed separately, put into a ball mill tank and mixed for ball milling, ball milling conditions: the volume ratio of raw material, agate ball volume, and ball milling medium anhydrous ethanol is approximately equal to 1:1.1 : 1.3, it was ball milled for 5 hours, and the raw material after ball milling was put into an oven and baked at 80° C. for 3 hours. After that, the dried raw materials are pressed into a raw material body with a diameter of 40mm by a tablet machine at 200Mpa, and then the pressed body is put into a KBF1400 box furnace for pre-burning, and the pre-fired condition is 700°C for 0.5 hours. Decompose the binder, then keep the temperature at 1200°C for 2 hours, crush the pre-fired block sample, grind it into powder, si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com