Non-phosphorus composite scale and corrosion inhibitor and preparation method thereof

A scale and corrosion inhibitor, phosphorus-free scale inhibition technology, applied in the chemical field, can solve the problems of aggravating the eutrophication of water bodies, achieve the effect of less usage, prevent the formation of various scales, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

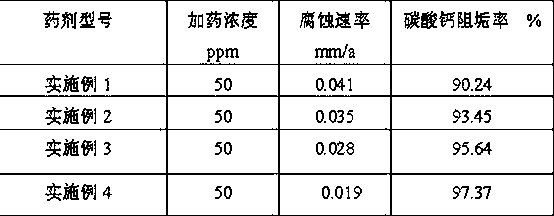

Examples

Embodiment 1

[0038] Raw materials are calculated by weight

[0039] step one:

[0040] Check whether the reactor is clean, close the valves, and add 24 parts of water to the reactor.

[0041] Step two:

[0042] Add 12 parts of zinc sulfate into the reaction kettle, raise the temperature to 50°C, and stir until completely dissolved.

[0043] Step three:

[0044] Add 13 parts of sodium gluconate to the reaction kettle and stir until all of them are dissolved.

[0045] Step four:

[0046] Add 15 parts of acrylic acid, 20 parts of polyaspartic acid, 1 part of mercaptobenzothiazole, and 15 parts of acrylic acid-2-acrylamido-2'-methylpropylsulfonic acid copolymer to the reactor in turn, mix and stir .

[0047] Step five:

[0048] After sampling and testing are qualified, the material is released, labeled and put into storage.

Embodiment 2

[0050] Raw materials by weight

[0051] step one:

[0052] Check whether the reactor is clean, close each valve, and add 29 parts of water to the reactor.

[0053] Step two:

[0054] Add 12 parts of zinc chloride into the reaction kettle, raise the temperature to 50°C, and stir until completely dissolved.

[0055] Step three:

[0056] Add 15 parts of sodium gluconate to the reaction kettle, and stir until it is completely dissolved.

[0057] Step four:

[0058] Add 13 parts of polymaleic anhydride, 15 parts of polyaspartic acid, 1 part of mercaptobenzothiazole, and 15 parts of acrylic acid-2-acrylamide-2'-methylpropyl sulfonic acid copolymer in order Mix and stir.

[0059] Step five:

[0060] After sampling and testing are qualified, the material is released, labeled and put into storage.

Embodiment 3

[0062] Raw materials by weight

[0063] step one:

[0064] Check whether the reactor is clean, close the valves, and add 32 parts of water to the reactor.

[0065] Step two:

[0066] Add 12 parts of zinc chloride into the reaction kettle, raise the temperature to 55°C, and stir until completely dissolved.

[0067] Step three:

[0068] Add 10 parts of sodium gluconate to the reaction kettle, and stir until completely dissolved.

[0069] Step four:

[0070] Add 15 parts of polymaleic acid, 15 parts of polyaspartic acid, 1 part of mercaptobenzothiazole, and 15 parts of acrylic acid-2-acrylamide-2'-methylpropylsulfonic acid copolymer into the reaction kettle in sequence Mix and stir.

[0071] Step five:

[0072] After sampling and testing are qualified, the material is released, labeled and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com