Method for reducing oxidizing and jamming of high-carbon steel intermediate billet in induction heating area

A technology of induction heating and blank oxidation card, which is applied in the field of iron oxide scale mitigation and control, can solve problems such as affecting the coiling rate, affecting the stable operation of IH, and heating module deformation, and achieves the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

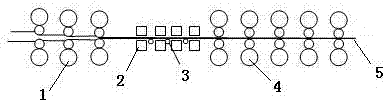

Image

Examples

Embodiment 1

[0037] A method for reducing the oxidation jamming of high-carbon steel intermediate billets in the induction heating area. The process route is: molten steel-ladle turret-tundish-crystallizer-sector section-rough rolling R1-R2-R3-induction heating furnace-high pressure Descaling - finishing rolling F1-F2-F3-F4-F5 - laminar cooling - coiler;

[0038] The composition is designed as: C: 0.17~0.70%, Si: 0.10~0.14%, Mn: 0.12~0.22%, Alt: 0.010~0.030%, S: ≤0.01%, P: ≤0.017%, O≤0.01%, N : ≤0.006%.

[0039] Tundish superheat 15-30 ℃, continuous casting casting speed ≥ 4.8m / min.

[0040] Rough rolling R3 outlet temperature ≥ 950 ℃ to ensure the induction heating inlet temperature, R3 outlet intermediate billet thickness 13-14mm.

[0041] The outlet temperature of induction heating is 1120°C-1125°C mainly to control the finish rolling temperature, and the finish rolling temperature is 800-815°C.

[0042] Layer cooling is carried out according to the cooling rate of 50% in the previou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com