Compound additive for polypropylene random copolymer tubular product

A technology of polypropylene pipes and composite additives, applied in the field of polymer material additives, which can solve the problems of product surface roughness, swelling, and affecting the long-term performance of PPR pipes, so as to improve surface flatness and smoothness, and improve hot water resistance Erosion performance and the effect of maintaining long-term weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

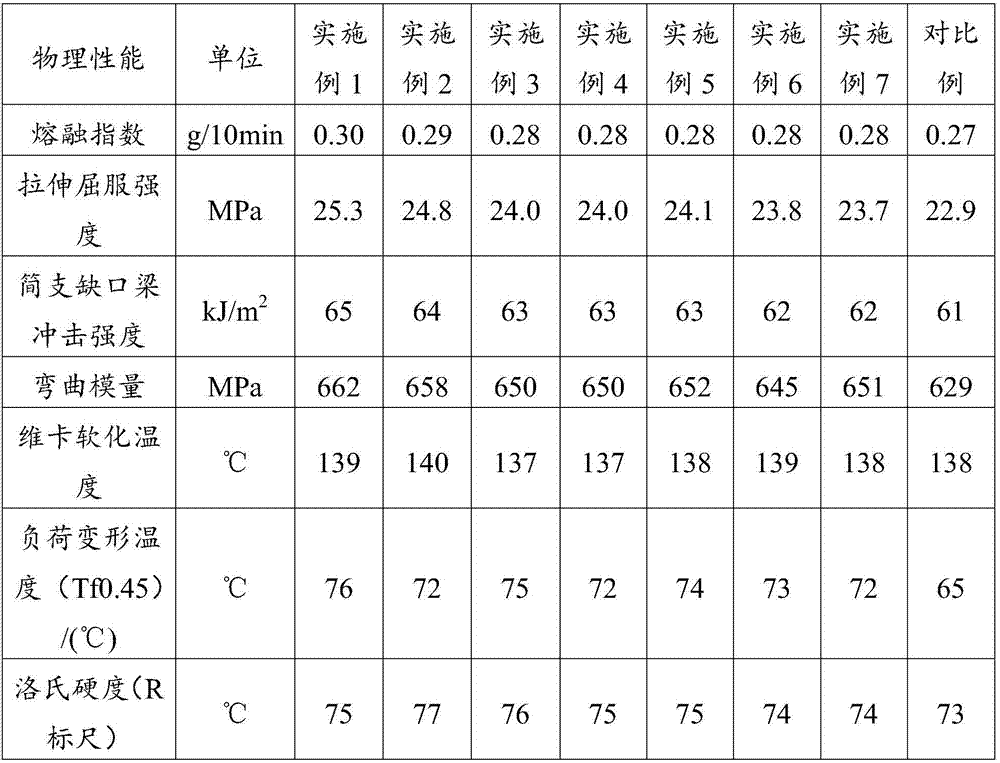

Examples

Embodiment 1

[0023] An embodiment of the composite additive for random copolymerized polypropylene pipes of the present invention, the composite additive for random copolymerized polypropylene pipes described in this embodiment includes the following components in parts by weight: 20 parts of processing aids, long-acting anti- 20 parts of oxygen agent, 40 parts of antioxidant and 20 parts of stearate.

[0024] Wherein, the processing aid is a mixture of fluorine-containing rubber polymer and oxidized polyethylene wax, and the weight ratio of the fluorine-containing rubber polymer and oxidized polyethylene wax is: fluorine-containing rubber polymer: oxidized polyethylene wax= 2:1; the long-acting antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene; the antioxidant It is a mixture of tris[2.4-di-tert-butylphenyl]phosphite and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]pentaerythritol ester, the tris[2.4- The weight ratio of di-tert-butylphenyl] pho...

Embodiment 2

[0029] An embodiment of the composite additive for random copolymerized polypropylene pipes of the present invention, the composite additive for random copolymerized polypropylene pipes described in this embodiment includes the following components in parts by weight: 20 parts of processing aids, long-acting anti- 30 parts of oxygen agent, 40 parts of antioxidant and 10 parts of stearate.

[0030] Wherein, the processing aid is a mixture of fluorine-containing rubber polymer and oxidized polyethylene wax, and the weight ratio of the fluorine-containing rubber polymer and oxidized polyethylene wax is: fluorine-containing rubber polymer: oxidized polyethylene wax= 1:1; the long-acting antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene; the antioxidant It is a mixture of tris[2.4-di-tert-butylphenyl]phosphite and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]pentaerythritol ester, the tris[2.4- The weight ratio of di-tert-butylphenyl] pho...

Embodiment 3

[0033]An embodiment of the composite additive for random copolymerized polypropylene pipes in the present invention, the composite additive for random copolymerized polypropylene pipes in this embodiment contains the following components in parts by weight: 10 parts of processing aids, long-acting anti- 10 parts of oxygen agent, 60 parts of antioxidant and 20 parts of stearate.

[0034] Wherein, the processing aid is a mixture of fluorine-containing rubber polymer and oxidized polyethylene wax, and the weight ratio of the fluorine-containing rubber polymer and oxidized polyethylene wax is: fluorine-containing rubber polymer: oxidized polyethylene wax= 1:2; the long-acting antioxidant is 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene; the antioxidant It is a mixture of tris[2.4-di-tert-butylphenyl]phosphite and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate]pentaerythritol ester, the tris[2.4- The weight ratio of di-tert-butylphenyl] phosphite and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com