Graphene modified cable material for high-voltage direct current cable and preparation method thereof

A graphene modification, high-voltage DC technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of poor mechanical properties of cable materials, easy dielectric breakdown, and poor filler dispersion, etc. It is suitable for large-scale promotion, improving coating efficiency and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

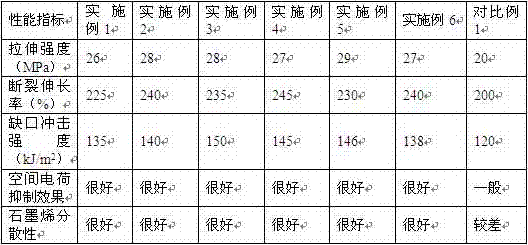

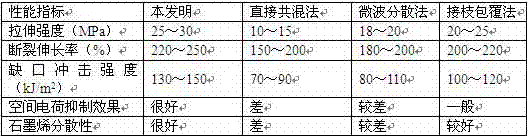

Examples

Embodiment 1

[0038] The parts by weight of the raw materials of the graphene modified cable material are:

[0039]0.3 parts of magnetic particles, 0.6 parts of gelatin, 6 parts of graphene micropowder, 4 parts of hyperbranched silicone urethane acrylate prepolymer, 0.7 parts of surfactant, 1 part of acetic acid solution, 3 parts of isopropanol, 0.7 parts of glutaraldehyde aqueous solution 1 part, 1 part of flame retardant, 0.7 part of stabilizer, 82 parts of matrix resin;

[0040] The magnetic particles are ferric oxide particles; the surfactant is Tween 20; the mass concentration of the acetic acid solution is 5%; the mass concentration of the glutaraldehyde aqueous solution is 25%; the flame retardant is tributyl phosphate; Salt lead sulfate; matrix resin is polyethylene;

[0041] The parts by weight of each component of the hyperbranched silicone urethane acrylate prepolymer are: 6 parts of trimethylolpropane, 14 parts of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester, 10 parts...

Embodiment 2

[0048] The parts by weight of the raw materials of the graphene modified cable material are:

[0049] 0.2 parts of magnetic particles, 0.4 parts of gelatin, 5 parts of graphene micropowder, 3 parts of hyperbranched silicone polyurethane acrylate prepolymer, 0.8 parts of surfactant, 2 parts of acetic acid solution, 2 parts of isopropanol, 0.6 parts of glutaraldehyde aqueous solution 1 part, 2 parts of flame retardant, 1 part of stabilizer, 83 parts of matrix resin;

[0050] The magnetic particles are ferric oxide particles; the surfactant is Tween 40; the mass concentration of the acetic acid solution is 4%; the mass concentration of the glutaraldehyde aqueous solution is 20%; the flame retardant is toluene-diphenyl phosphate; the stabilizer It is lead stearate; the matrix resin is polyvinyl chloride;

[0051] The parts by weight of each component of the hyperbranched silicone urethane acrylate prepolymer are: 4 parts of trimethylolpropane, 12 parts of N,N-dihydroxyethyl-3-ami...

Embodiment 3

[0058] The parts by weight of the raw materials of the graphene modified cable material are:

[0059] 0.5 parts of magnetic particles, 0.8 parts of gelatin, 7 parts of graphene micropowder, 5 parts of hyperbranched silicone urethane acrylate prepolymer, 0.5 parts of surfactant, 1 part of acetic acid solution, 4 parts of isopropanol, 0.6 parts of glutaraldehyde aqueous solution part, 2 parts of flame retardant, 0.6 part of stabilizer, 78 parts of matrix resin;

[0060] The magnetic particles are ferric oxide particles; the surfactant is Tween 60; the mass concentration of acetic acid solution is 6%; the mass concentration of glutaraldehyde aqueous solution is 30%; the flame retardant is chlordane anhydride; the stabilizer is trisalt base lead salicylate; base resin is polypropylene;

[0061] The parts by weight of each component of the hyperbranched silicone urethane acrylate prepolymer are: 8 parts of trimethylolpropane, 14 parts of N,N-dihydroxyethyl-3-aminopropionic acid me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com