Preparation method of fracturing supercritical carbon dioxide thickener containing siloxane polymer

A carbon dioxide and polymer technology, applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc. Thickening effect, enhanced fracturing performance, excellent thickening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

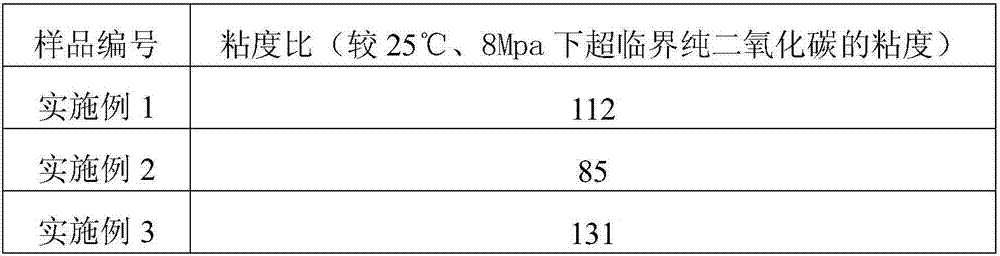

Examples

Embodiment 1

[0060] A preparation method of siloxane polymer supercritical carbon dioxide thickener for fracturing, the steps are as follows:

[0061] 1) Preparation of modified polydimethylsiloxane with aminopropyl terminated vinyl side chain

[0062] Under the protection of nitrogen, add 2.1 g of deionized water dropwise to a three-neck flask 1 containing 10.4g of aminopropyltriethoxysilane at 25°C and react for 5 hours. Dissolve the viscous hydrolysate in 100mL of toluene at 25°C and stir for 1-7 hours. ,Stand for layers, separate the remaining deionized water, and remove toluene by rotary evaporation at 100°C. The remaining product was added to a three-necked flask 2 containing 35.4g of tetramethyltetravinylcyclotetrasiloxane and 63g of octamethylcyclotetrasiloxane, and 0.25g of tetramethylammonium hydroxide was added and reacted at 85°C for 18h, and then removed. Set the layers to remove tetramethylammonium hydroxide, wash with saturated brine, remove ionized water and low-boiling substan...

Embodiment 2

[0070] As described in Example 1, the difference is that the amount of deionized water used in step (1) is 1.1 g.

Embodiment 3

[0072] As described in Example 1, the difference is that the amount of tetramethyltetravinylcyclotetrasiloxane used in step (1) is 45 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com