Coal mine underground gas extraction long drilled hole and coiled-tubing-in-casing perforation staged fracturing method

A technology of gas drainage and staged fracturing, which is applied in the direction of gas discharge, mining fluid, mining equipment, etc. Difficult boreholes and other problems, to achieve good fracturing effects, low construction friction, and improve drilling gas drainage volume and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

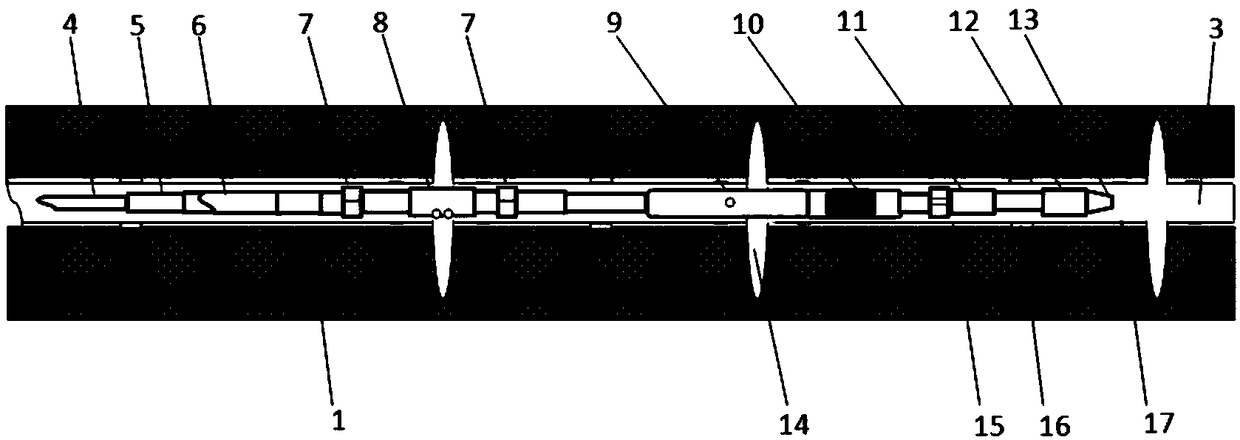

[0039] see figure 1 , shows the coal mine underground coal seam roof gas drainage method for staged fracturing with coiled tube perforation in long borehole casing of the present invention.

[0040] The continuous pipe perforation segmental fracturing method in the long borehole casing for gas drainage in the coal mine comprises the following steps:

[0041] Step 1: Under the coal mine, from the roof 2 of mudstone or sandstone at a certain distance from the top boundary of the broken soft coal seam 1, drill a gas drainage long borehole 3 of a preset length;

[0042] Specifically, the directional construction of the gas drainage long borehole 3 is carried out from the bottom slate roadway or the roof slate roadway by using the tunnel directional drilling rig for coal mines. The horizontal section of the gas drainage long borehole 3 is located above the top of the broken soft coal seam 1 In the roof 2 of mudstone or sandstone between 0.5m-2m, the drilling length is preferably g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com