Controllable pulse gas energy pressure cracking device

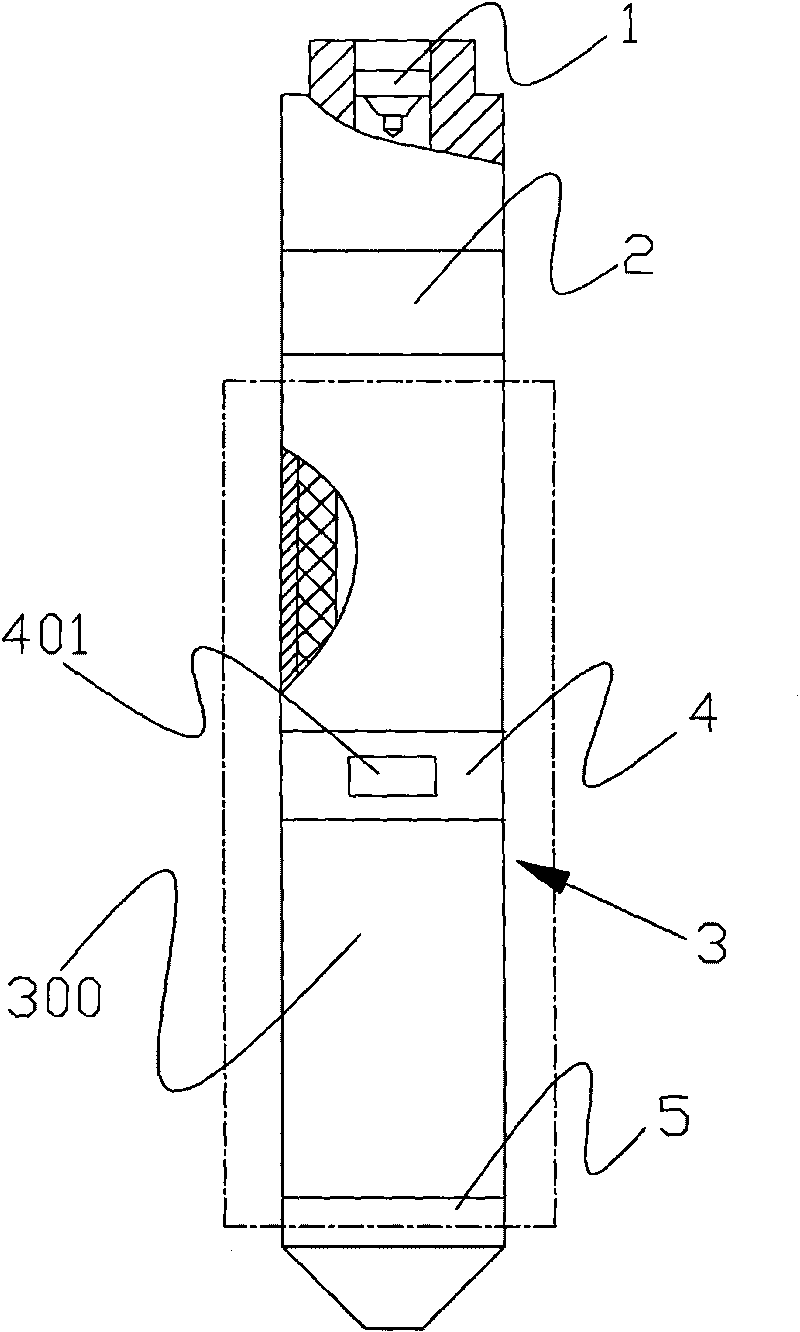

A gas energy and pulse technology, applied in the field of controllable pulse gas energy fracturing device, can solve the problems of uncontrollable fracturing process, inability to achieve effective connection between formation and wellbore, low productivity, etc. Large quantity, safe and reliable construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

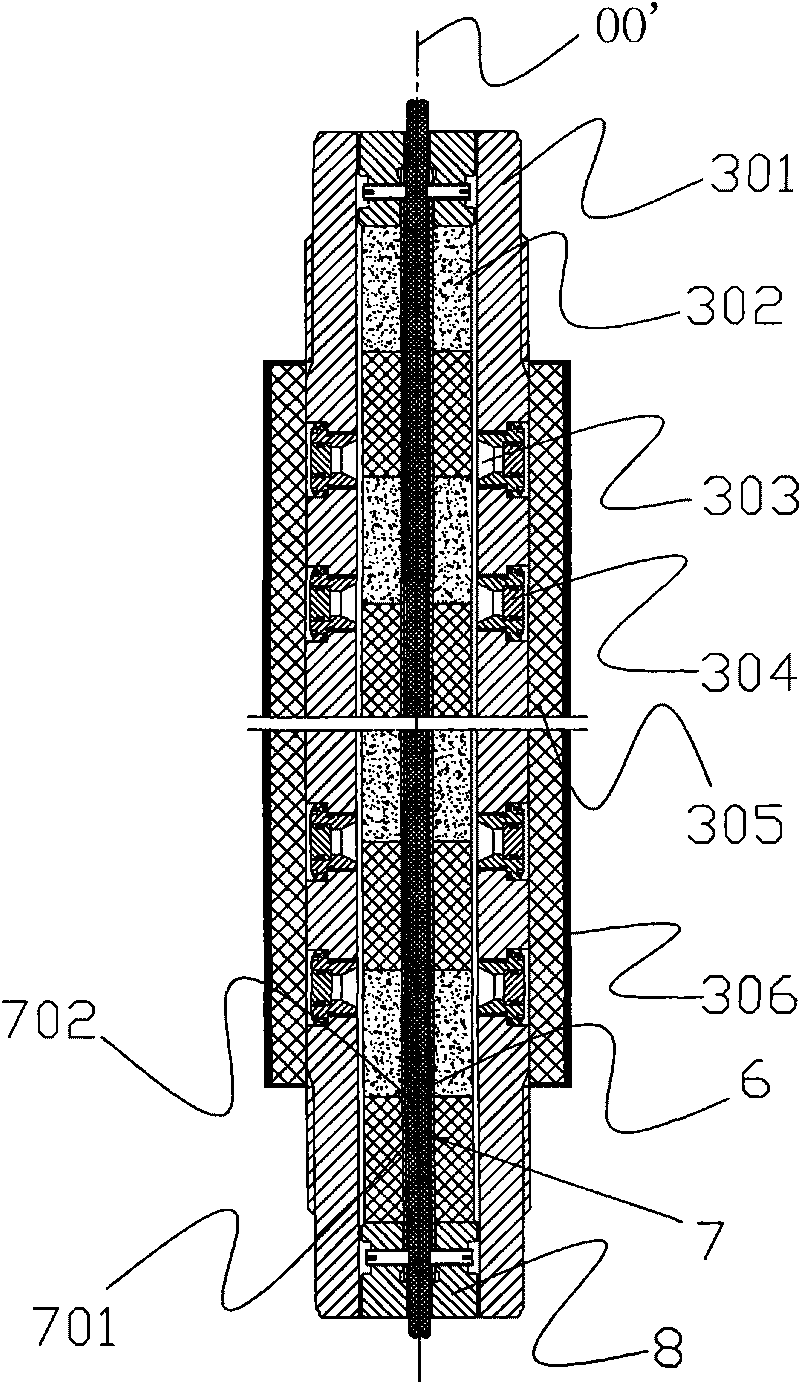

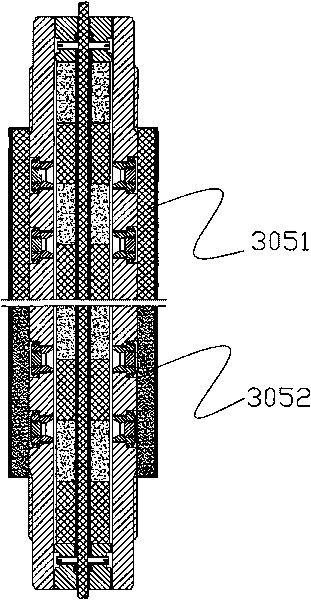

[0039]In the present invention, according to the principle of clapboard detonation transmission, detonation-to-combustion mechanism and two-stage ignition principle, the detonator or ignition / initiator 1 is detonated, and the internal charge column 302 in the central tube 301 is rapidly excited through the ignition channel 7, and the ignited internal charge The column 302 detonates or burns to form high pressure gas and hot metal particles, producing a high pressure deflagration gas. The primary high-pressure gas pushes away the channel sealing cover 304 of the pressure relief fire transmission channel 303 on the central tube 301, and the red-hot metal particles ignite the outer cartridge 305 along with the high-pressure airflow to form a secondary pulse high-energy combustion gas. The inner drug column 302, the outer drug barrel 305 and the waterproof sealing protective layer 306 made of energetic materials burn in sequence, effectively prolonging the pressure platform, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com