Low damage carboxymethyl hydroxypropyl guanidine gum foam fracturing fluid of low permeability gas reservoir and preparation method of low damage carboxymethyl hydroxypropyl guanidine gum foam fracturing fluid

A technology of carboxymethyl hydroxypropyl guanidine and foam fracturing fluid, which is applied in the field of fracturing and stimulation, can solve the problems of reservoir water damage to fracturing effect, high residue content, difficult flowback, etc., and achieve ideal fracturing effect, The effect of low residue content and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

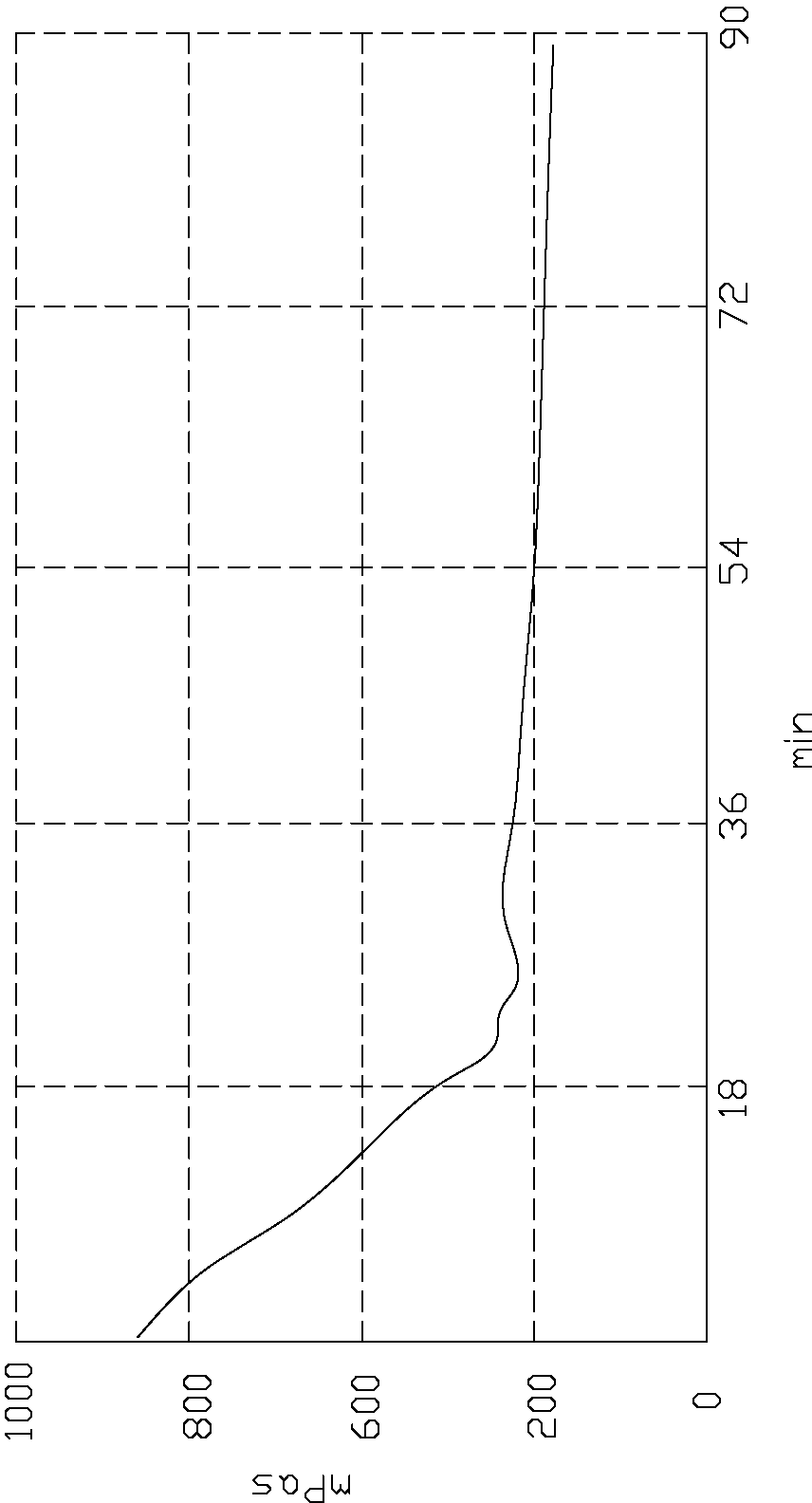

Image

Examples

Embodiment 1

[0015] Embodiment 1, the low-damage carboxymethyl hydroxypropyl guar gum foam fracturing fluid of the low-permeability gas reservoir contains 100 parts by weight of base liquid, 0.2 to 0.5 parts of crosslinking agent, and 0.03 to 0.03 parts of gel breaker. 0.04 parts, liquid nitrogen, the volume of liquid nitrogen is 5% to 7% of the total volume of base liquid and crosslinking agent.

Embodiment 2

[0016] Embodiment 2, the low-damage carboxymethyl hydroxypropyl guar gum foam fracturing fluid of the low-permeability gas reservoir contains 100 parts of base liquid, 0.2 or 0.5 parts of crosslinking agent, and 0.03 or 0.03 parts of breaker by weight. 0.04 parts, liquid nitrogen, the volume of liquid nitrogen is 5% or 7% of the total volume of base liquid and crosslinking agent.

Embodiment 3

[0017] Example 3, the base liquid contains 0.25 to 0.4 parts of carboxymethyl hydroxypropyl guar gum, 0.5 parts of clay stabilizer, 0.5 part of drainage aid, 0.1 part of bactericide, and 0.2 to 0.3 parts of crosslinking accelerator by weight. 98.2 to 98.45 parts of water. When carboxymethyl hydroxypropyl guar gum is added to water, it is easy to increase the viscosity, which is conducive to stirring into a uniform mixture without forming "fish eyes", which is not only convenient for liquid preparation, but also prevents the "fish eyes" from breaking the glue and affecting the reservoir s damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com