Process and device for continuously producing high-quality N-fatty acyl amino acid salt surfactant

A fatty acyl amino acid and surfactant technology, applied in the field of daily chemical industry, can solve problems such as residue, product quality, application impact, etc., and achieve the effect of reducing the formation of fatty acid sodium and inhibiting invalid decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

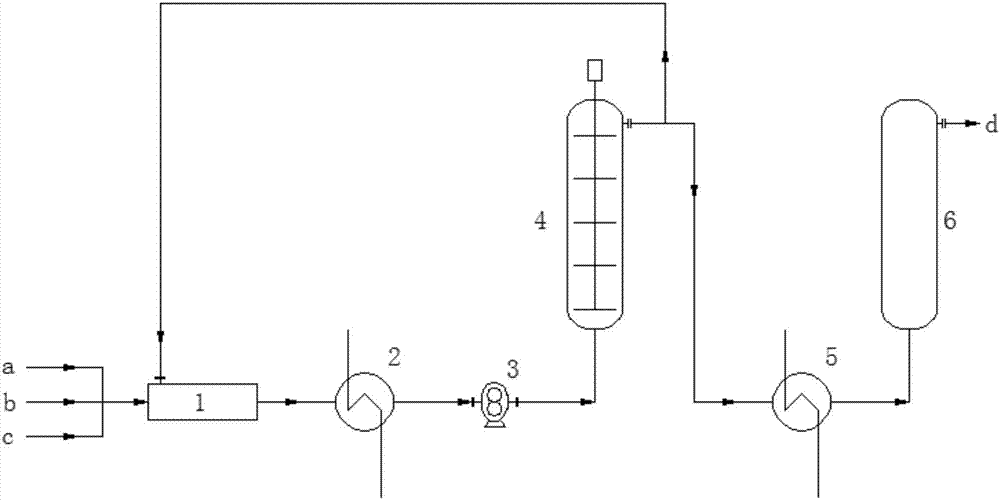

Embodiment 1

[0050] Embodiment 1: the mass concentration is 20% amino acid mixture aqueous solution (wherein the mass ratio of alanine and lysine is 100:8), lauroyl chloride, mass concentration are 20% liquid caustic soda respectively enter mixing device and mix homogeneously, wherein The feed rate of amino acid mixture aqueous solution is 108kg / h, the feed rate of lauroyl chloride is 40kg / h, the flow rate of liquid caustic soda is automatically adjusted according to the pH meter reading, and the pH is controlled at 9.5 ± 0.2; the speed of circulating reaction materials is 1000kg / h; After being cooled by the cooler, it is transported to the amidation column by the delivery pump for amidation reaction. The reaction temperature is controlled at 20°C, and the residence time of the reaction material in the amidation column is 5h; the reacted product enters the aging kettle at a rate of 200kg / h , control the aging temperature to 60°C, and the aging time to 6h; the rest of the reacted products en...

Embodiment 2

[0051] Embodiment 2: mass concentration is 25% amino acid mixture aqueous solution (wherein the mass ratio of alanine and lysine is 100:10), cocoyl chloride, mass concentration are that 15% liquid caustic soda enters mixing device respectively and mixes evenly, Wherein the feed rate of the amino acid mixture aqueous solution is 50kg / h, the feed rate of the acid chloride is 36kg / h, the flow rate of the liquid caustic soda is automatically adjusted according to the pH meter reading, and the pH is controlled at 10.0 ± 0.2; the speed of the circulating reaction material is 1000kg / h; After being cooled by the cooler, it is transported to the amidation column by the delivery pump for amidation reaction, the reaction temperature is controlled at 18°C, and the residence time of the reaction material in the amidation column is 6h; the reacted product enters the aging kettle at a rate of 160kg / h , the aging temperature is controlled to be 70°C, and the aging time is 4h; the rest of the r...

Embodiment 3

[0052] Embodiment 3: the aqueous solution of amino acid mixture that mass concentration is 15% (wherein the mass ratio of alanine and arginine is 100:2), lauroyl chloride, mass concentration is that 32% liquid caustic soda enters mixing device respectively and mixes evenly, wherein The feed rate of the amino acid mixture aqueous solution is 152kg / h, the feed rate of the acid chloride is 50kg / h, the flow of liquid caustic soda is automatically adjusted according to the pH meter reading, and the pH is controlled at 10.5 ± 0.2; the speed of the circulating reaction material is 1000kg / h; After the cooler cools down, use the transfer pump to transport it to the amidation column for amidation reaction. The reaction temperature is controlled at 15°C. The residence time of the reaction material in the amidation column is 4h; the reacted product enters the aging kettle at 250kg / h. The aging temperature is controlled at 50°C, and the aging time is 8 hours; the rest of the reacted product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com