Non-phosphorus corrosion and scale inhibitor

A corrosion and scale inhibitor, phosphorus-free corrosion inhibition technology, applied in the field of industrial circulating cooling water treatment, can solve the problem of destroying the ecological balance of water bodies, and achieve good synergistic effects, good compatibility, and good corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with specific embodiments.

[0034] The components and raw materials are all commercially available industrial products.

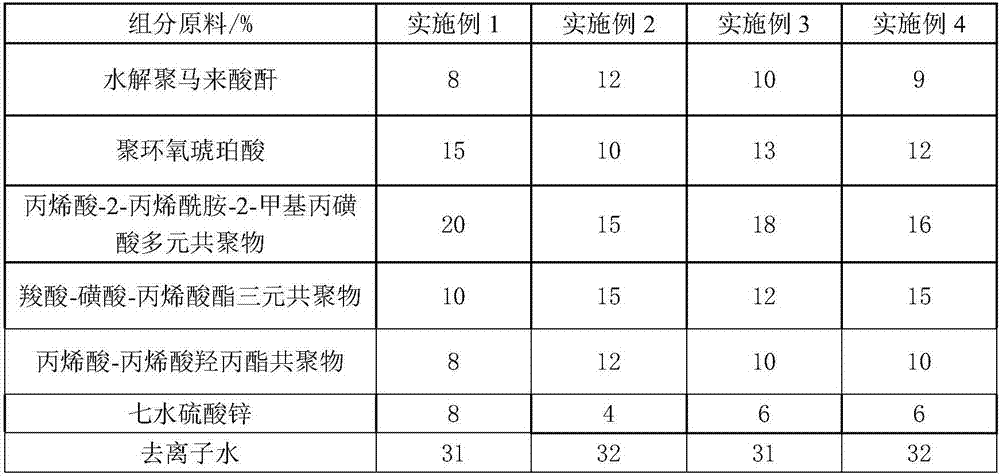

[0035] The formula of corrosion and scale inhibitor is shown in Table 1

[0036] Table 1 Corrosion and scale inhibitor formula

[0037]

[0038] Any embodiment in the above table is prepared according to the following method: hydrolyzed polymaleic anhydride, polyepoxysuccinic acid, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid multipolymer, carboxylic acid-sulfonic acid- Acrylate terpolymer, acrylic acid-hydroxypropyl acrylate copolymer, zinc sulfate heptahydrate and deionization were added into the stirring vessel in turn, and the product was obtained under normal temperature and pressure with stirring speed of 80r / min and stirring for 90min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com