Sand blasting device for valve body machining

A technology of sandblasting device and valve body, which is applied to used abrasive treatment devices, metal processing equipment, abrasive feeding devices, etc. Conducive to leveling and decoration, avoiding material agglomeration and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

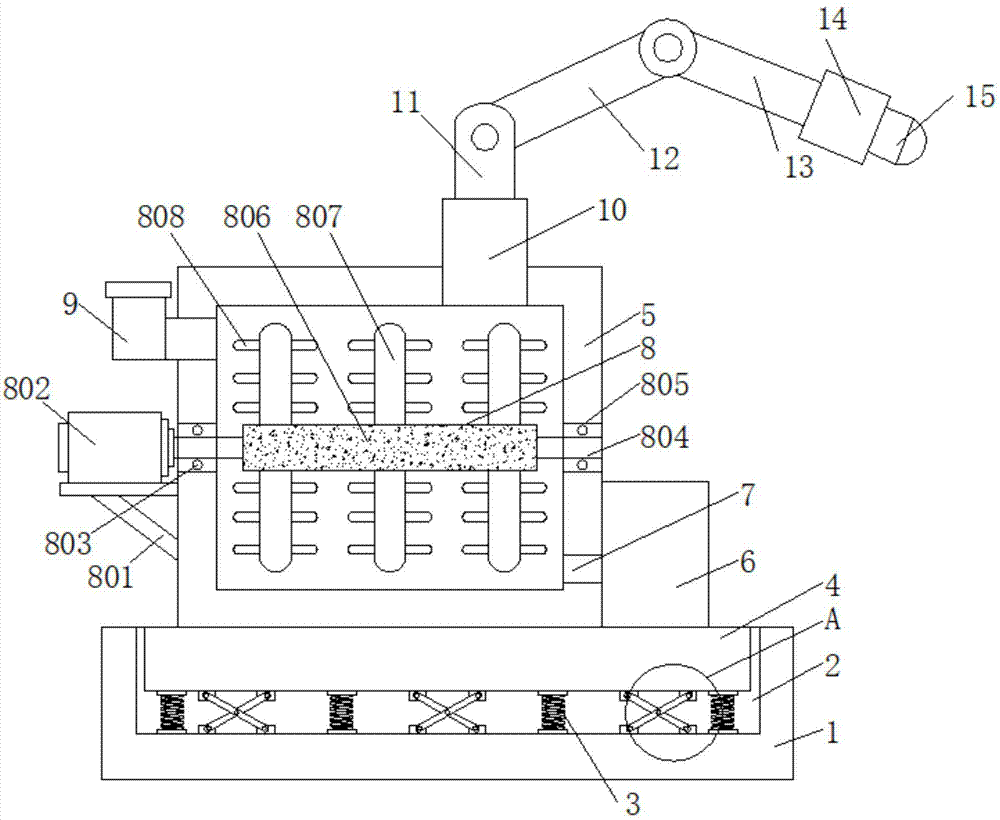

[0030] A sandblasting device for valve body processing, comprising a base 1, a groove 2 is provided in the middle of the top of the base 1, a shock absorbing device 3 is fixedly connected to the inner top wall of the groove 2, and a mounting device 3 is fixedly connected to the top of the shock absorbing device 3 Block 4, one side of the top of the installation block 4 is fixedly connected to the sand storage box 5, and the other side of the top of the installation block 4 is fixedly connected to the air compressor 6, and the exhaust of the air compressor 6 is connected to the sand storage box through the connecting pipe 7. One side of the sand storage box 5 is fixedly connected, and the inside of the sand storage box 5 is provided with a stirring device 8. The top of the sand storage box 5 away from the air compressor 6 is fixedly connected with a feeding hopper 9, and the top of the sand storage box 5 is fixedly connected with a sand outlet. Pipe 10, the top of the sand outle...

Embodiment 2

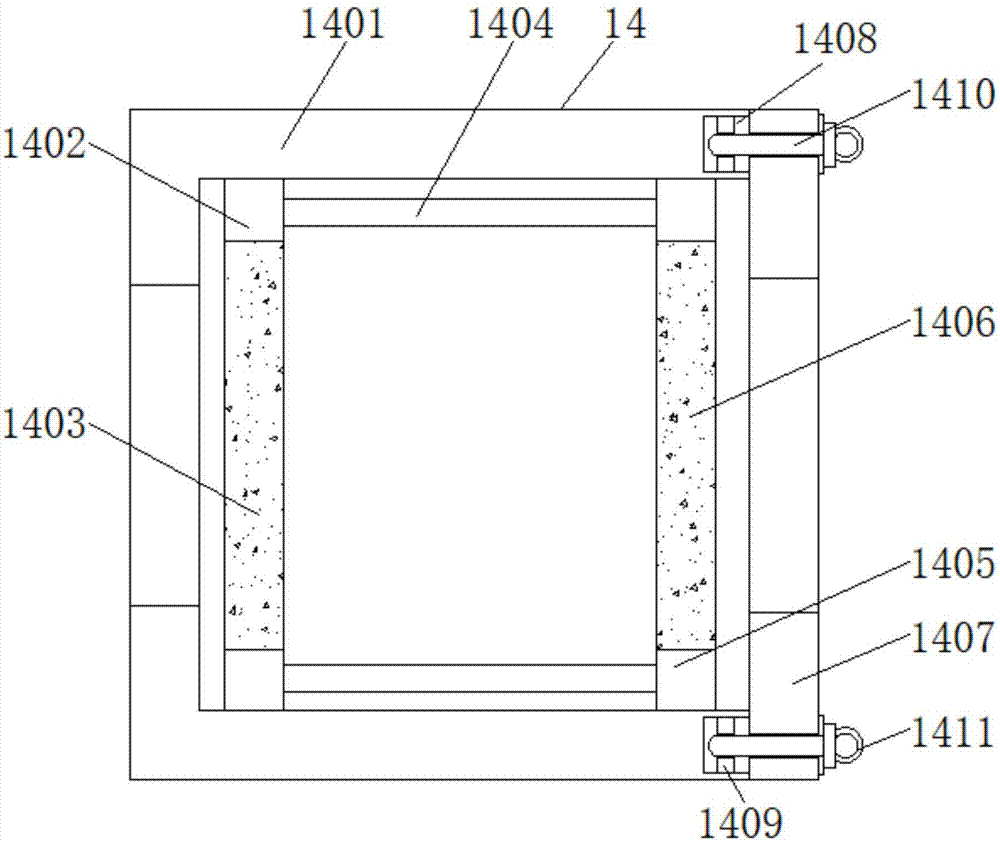

[0032] A sandblasting device for valve body processing, comprising a base 1, a groove 2 is provided in the middle of the top of the base 1, a shock absorbing device 3 is fixedly connected to the inner top wall of the groove 2, and a mounting device 3 is fixedly connected to the top of the shock absorbing device 3 Block 4, one side of the top of the installation block 4 is fixedly connected to the sand storage box 5, and the other side of the top of the installation block 4 is fixedly connected to the air compressor 6, and the exhaust of the air compressor 6 is connected to the sand storage box through the connecting pipe 7. One side of the sand storage box 5 is fixedly connected, and the inside of the sand storage box 5 is provided with a stirring device 8. The top of the sand storage box 5 away from the air compressor 6 is fixedly connected with a feeding hopper 9, and the top of the sand storage box 5 is fixedly connected with a sand outlet. Pipe 10, the top of the sand outle...

Embodiment 3

[0035] A sandblasting device for valve body processing, comprising a base 1, a groove 2 is provided in the middle of the top of the base 1, a shock absorbing device 3 is fixedly connected to the inner top wall of the groove 2, and a mounting device 3 is fixedly connected to the top of the shock absorbing device 3 Block 4, one side of the top of the installation block 4 is fixedly connected to the sand storage box 5, and the other side of the top of the installation block 4 is fixedly connected to the air compressor 6, and the exhaust of the air compressor 6 is connected to the sand storage box through the connecting pipe 7. One side of the sand storage box 5 is fixedly connected, and the inside of the sand storage box 5 is provided with a stirring device 8. The top of the sand storage box 5 away from the air compressor 6 is fixedly connected with a feeding hopper 9, and the top of the sand storage box 5 is fixedly connected with a sand outlet. Pipe 10, the top of the sand outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com