Ni-based catalyst prepared through solution combustion and method thereof

A nickel-based catalyst, solution combustion technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve uneven distribution of active substances, poor 1,4-butanediol selectivity, 1 ,4-butynediol conversion rate is not high, to achieve the effect of high conversion rate and selectivity, good stability and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

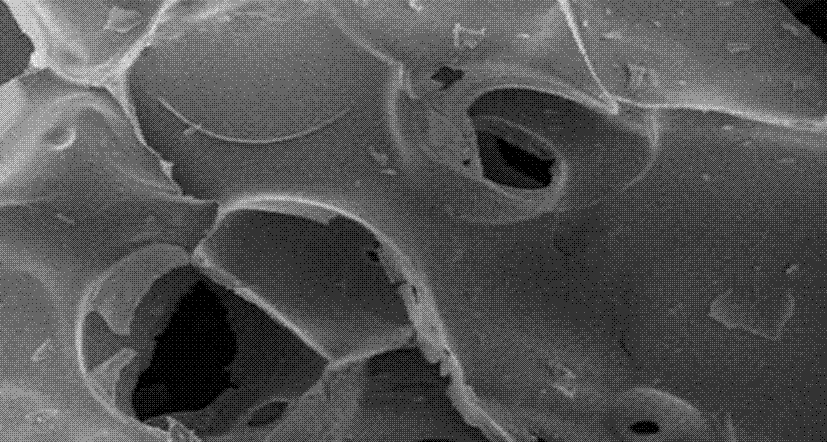

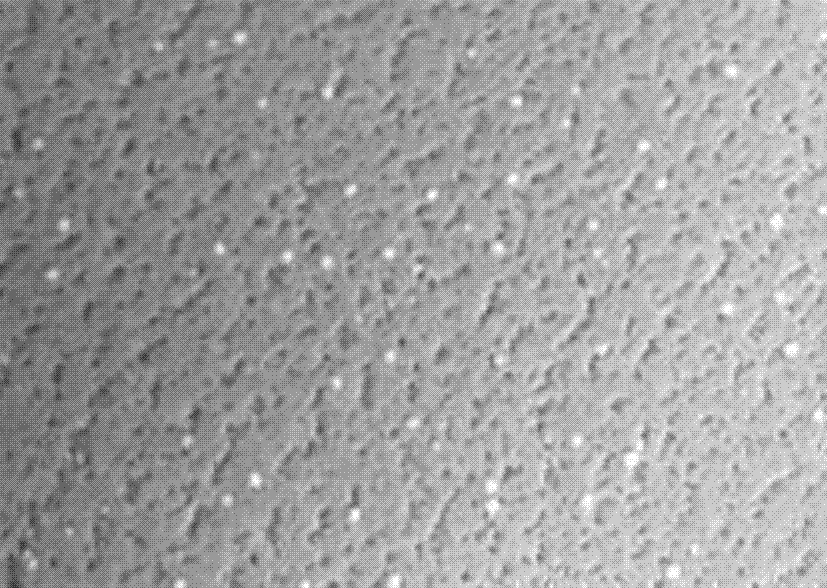

[0018] Embodiment 1: this nickel-based catalyst prepared by the solution combustion process obtains as follows: the first step, take a certain amount of nickel nitrate hexahydrate or nickel acetate or a kind of in nickel chloride, and nonaqueous One of aluminum nitrate, aluminum acetate or aluminum chloride, with polypyrrolidone as a shape control agent, mixed with deionized water and ethylene glycol with a volume ratio of 1:1 to obtain a mixed solution, and ultrasonicated for 20 to 30 minutes , to prepare a precursor test solution, the amount of polypyrrolidone added is 0.1% to 0.5% of the total mass of raw materials, the concentration of metal nickel ions in the precursor test solution is 0.05 mol / L to 1.28 mol / L, and the concentration of aluminum ions is 0.49 mol / L; in the second step, put the precursor test solution in a muffle furnace, program the temperature from room temperature to 400 ℃ to 800 ℃, burn for 6 hours to 8 hours, take it out, cool, grind, sieve, and use 40 ...

Embodiment 2

[0019] Embodiment 2: this nickel-based catalyst prepared by solution combustion process obtains as follows: the first step, take a certain amount of nickel nitrate hexahydrate or nickel acetate or a kind of in nickel chloride respectively, and nonaqueous One of aluminum nitrate, aluminum acetate or aluminum chloride, with polypyrrolidone as a shape control agent, mixed with deionized water and ethylene glycol with a volume ratio of 1:1 to obtain a mixed solution, and ultrasonicated for 20 to 30 minutes , to prepare the precursor test solution, the addition amount of polypyrrolidone is 0.1% or 0.5% of the total mass of raw materials, the metal nickel ion concentration in the precursor test solution is 0.05 mol / L or 1.28 mol / L, and the aluminum ion concentration is 0.49 mol / L; in the second step, place the precursor test solution in a muffle furnace, program the temperature from room temperature to 400 °C or 800 °C, burn for 6 hours or 8 hours, take it out, cool, grind, sieve, u...

Embodiment 3

[0020] Embodiment 3: As the control of the programmed temperature rise rate in the above embodiment, the programmed temperature rise rate is 10° C. / min to 40° C. / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com