Regeneration method for supported noble metal catalyst

A precious metal catalyst and supported technology, which is applied in the regeneration field of supported precious metal catalysts, can solve certain problems in stability control and amplification, no reports of industrial application, influence on catalyst stability, etc. Sulfur-containing impurities, the effect of reducing catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a 2L hydrogenation autoclave, add 1400g of nitro T acid with a mass concentration of 20% and 0.28g of a Pd / C catalyst with a loading rate of 5%. Put on the autoclave, and use nitrogen and hydrogen to exhaust the air in the autoclave 3 times each , Fill with hydrogen, start stirring, and carry out hydrogenation reaction. The reaction temperature is 60°C and the pressure is 1.5MPa. Use a hydrogen mass flow meter to monitor the end of the reaction. When the hydrogen is not consumed, stop stirring, close the hydrogen inlet valve, cool down, discharge the residual gas in the kettle, open the kettle, the reaction mother liquor is filtered out of the catalyst, and the filtrate is analyzed by liquid chromatography. Calculate raw material conversion rate and product selectivity; the catalyst is directly used without any treatment. The results are shown in Table 1:

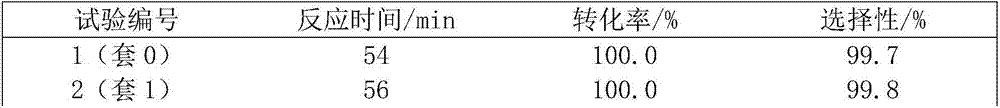

[0028] Table 1 Application of the catalyst in Example 1

[0029]

[0030]

Embodiment 2

[0032] Filter out the Pd / C catalyst from the reaction mother liquor in the above-mentioned embodiment set 9 and add all of it to a 100 mL autoclave, and then add 30 g of Na with a mass concentration of 0.25% 2 CO 3 Aqueous solution, put on the kettle to ensure that there is no leakage, first replace the air in the kettle with nitrogen three times, and then use CO 2 Replace the nitrogen in the kettle three times, and finally fill with CO with a total pressure of 0.8MPa and a volume ratio of 2:1 2 With O 2 Start stirring, heat to 140°C, and continue stirring at this temperature for 3.5 hours, turn off stirring and heating, wait to cool to room temperature, filter, and wash the filter cake with deionized water to neutral;

[0033] Transfer the catalyst treated in the above steps to a 50mL flask, add 20g of tetrahydrofuran solvent, stir, heat to 40°C, and add 0.8g N dropwise 2 H 4 .H 2 O, after dripping, continue to stir for 2.0h, filter, first wash with tetrahydrofuran, and then wash t...

Embodiment 3

[0038] The Pd / C catalyst in the reaction mother liquor of the set 9 of Example 2 was filtered out as described above, and the catalyst was regenerated using the same method as that of Example 2, and the regenerated catalyst was applied. The experimental method was the same as that of Example 1. The results are shown in Table 3:

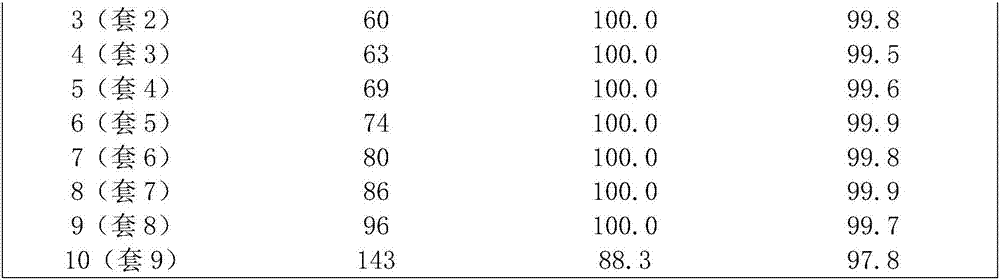

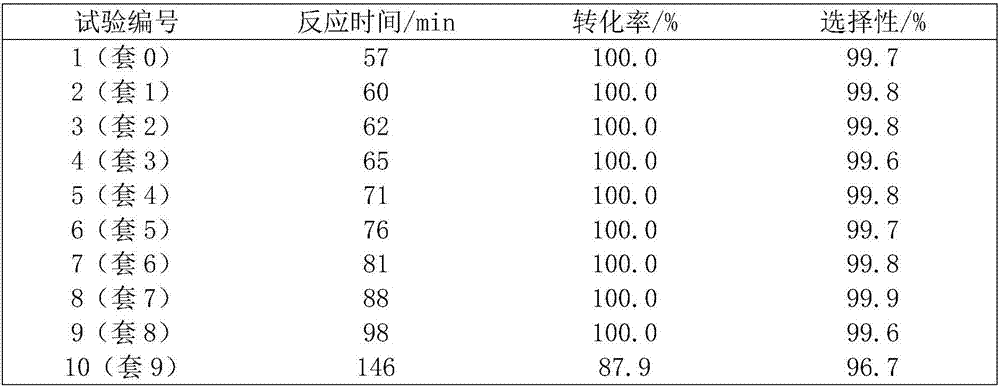

[0039] Table 3 Application of the catalyst in Example 3

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com