A kind of oral pharmaceutical preparation with sustained release effect and preparation method thereof

A pharmaceutical preparation and oral cavity technology, which is applied in the field of pharmaceutical preparation, can solve the problem that oral bactericidal drugs cannot obtain the ideal slow-release effect, and achieve the effect of inhibiting the growth of oral bacteria and prolonging the release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

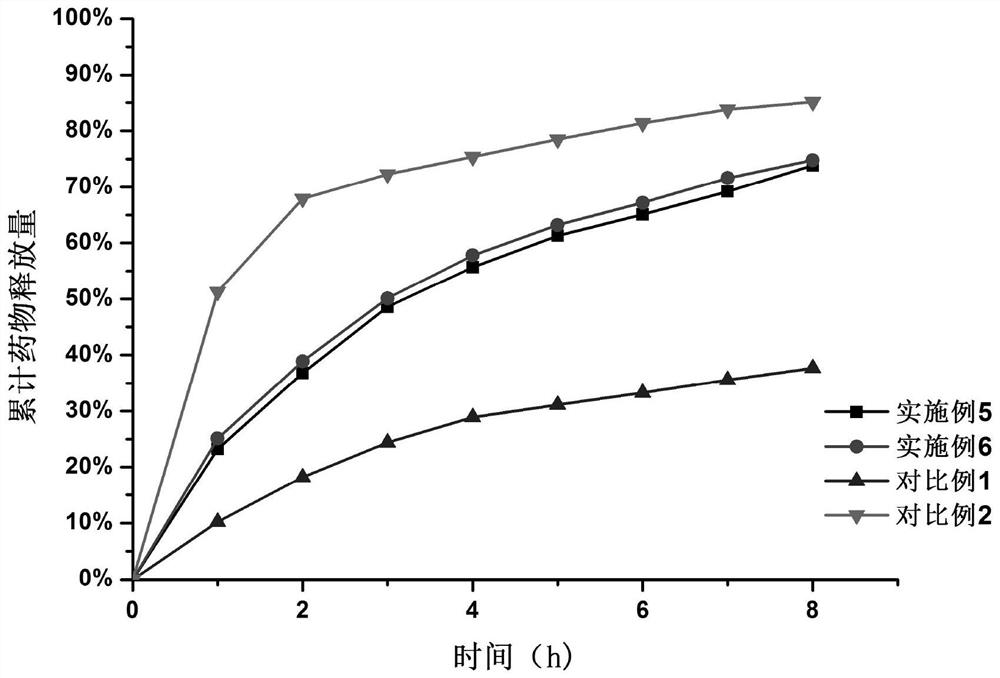

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned oral pharmaceutical preparation, comprises the following steps:

[0045] The ethanol solvent is used to dissolve and disperse 5-20 parts of the controlled-release agent, 60-90 parts of the forming agent and 5-20 parts of the bactericidal drug to obtain a sample stock solution with a mass fraction of 5%-20%.

[0046] And through the spray dryer, the parameters are set as follows:

[0047] Injection rate 10-40mL / min, air volume 50-70m 3 / h, atomization air pressure 0.1-0.2Mpa, air inlet temperature 140-160°C, needle pass frequency 60S, and powder particles were prepared.

Embodiment 1

[0050] A preparation method of an oral pharmaceutical preparation with sustained-release effect, comprising the following process steps:

[0051] Add 10 parts of cetylpyridinium chloride, 30 parts of triacetyl-β-cyclodextrin, 50 parts of ethyl cellulose, and 10 parts of stearic acid into the beaker, and add 75% ethanol solution, heat and stir at 40°C until Mix evenly to obtain a sample stock solution with a mass fraction of 10%, and pass it through a spray dryer. The parameters are set as follows: sample injection rate 10mL / min, air volume 60m 3 / h, atomization air pressure 0.1Mpa, air inlet temperature 140°C, needle pass frequency 60S, and powder particles with a particle size of 5 μm were prepared.

Embodiment 2

[0053] A preparation method of an oral pharmaceutical preparation with sustained-release effect, comprising the following process steps:

[0054] Add 15 parts of cetylpyridinium chloride, 75 parts of ethyl cellulose, and 10 parts of stearic acid into a beaker, and add 75% ethanol solution, heat at 40°C and stir until evenly mixed to obtain a sample with a mass fraction of 10% Stock solution, and through the spray dryer, the parameters are set as follows: injection rate 10mL / min, air volume 60m 3 / h, atomization air pressure 0.1Mpa, air inlet temperature 140°C, needle pass frequency 60S, and powder particles with a particle size of 5 μm were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com