High-tolerant UV environment-friendly clear varnish for Americian solid wooden cabinet

A transparent varnish, high-resistance technology, used in coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high organic volatiles, human injury, low efficiency, etc., to achieve good weather resistance, fast drying speed, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

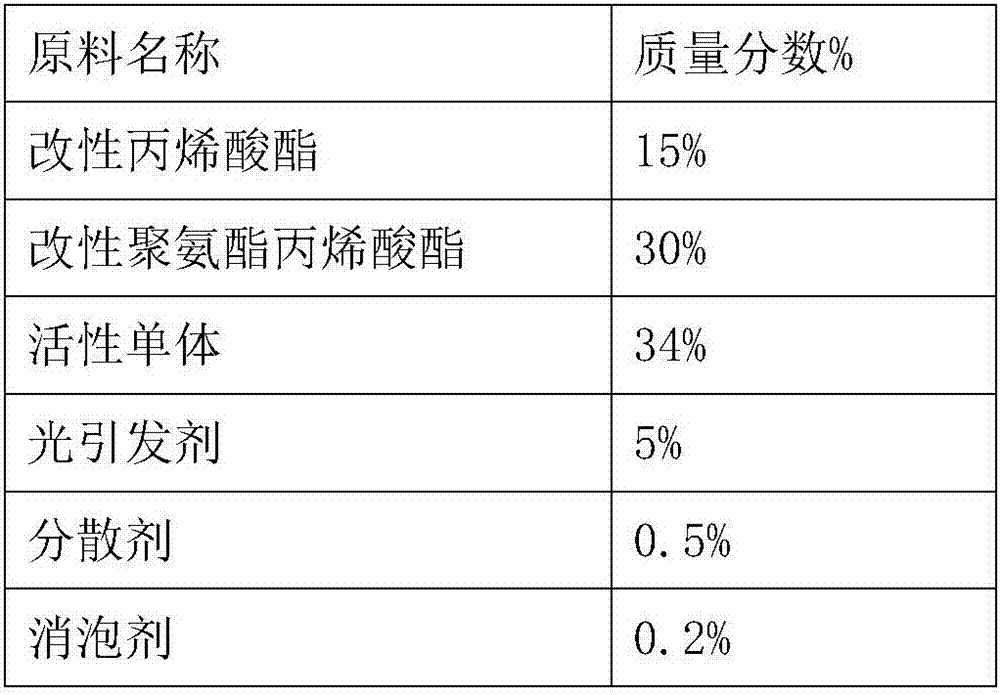

[0030] Embodiment 1: primer preparation proportioning:

[0031]

[0032]

[0033] Viscosity: 100cp.

[0034] raw material name

mass fraction%

15%

Modified epoxy acrylate

30%

active monomer

40.3%

5%

Dispersant

1%

0.2%

matting powder

8%

leveling agent

0.5%

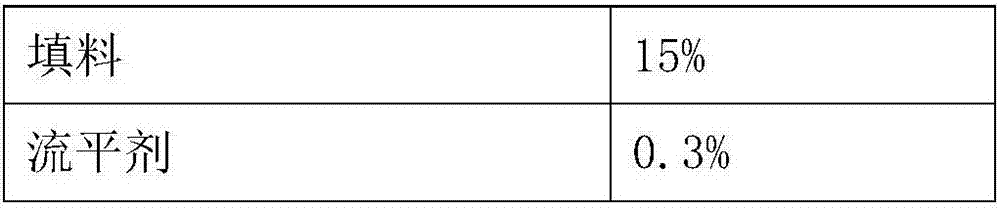

[0035] raw material name

Modified acrylate

12%

Modified polyurethane acrylate

33%

active monomer

34%

5%

Dispersant

0.5%

0-1%

filler

15%

leveling agent

0.3%

[0036] Viscosity: 100cp.

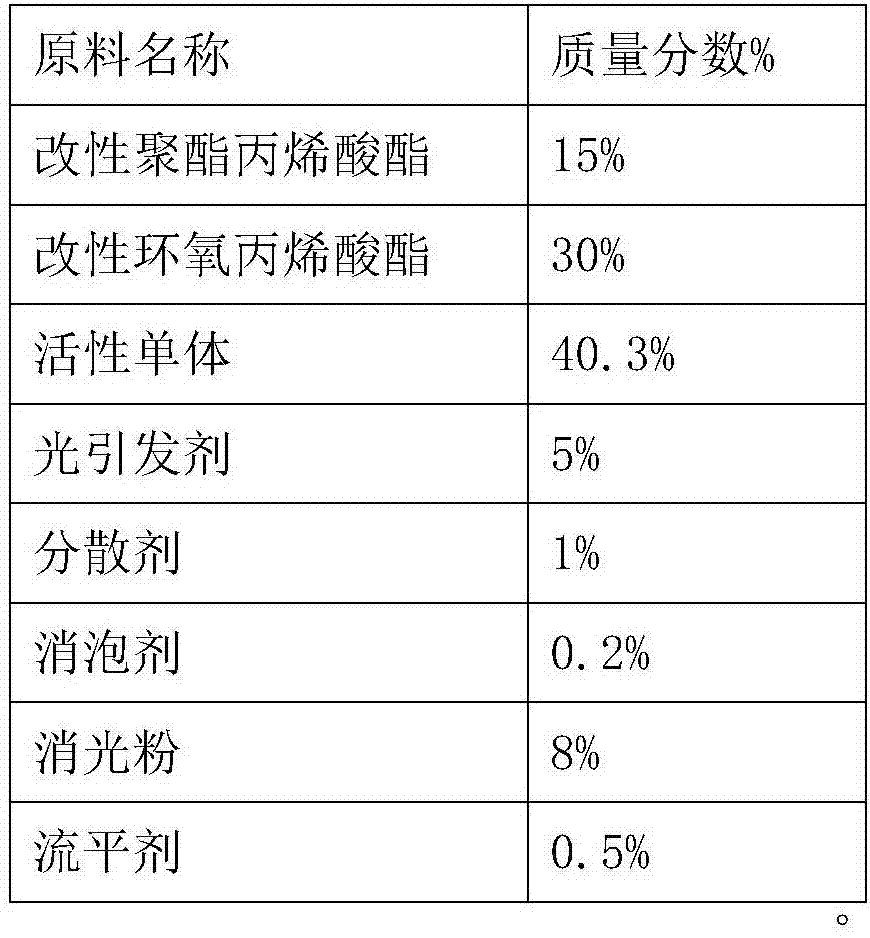

[0037] raw material name

20%

Modified epoxy acrylate

25%

active monomer

40.3%

5%

Dispersant

1%

Defoame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com