Automatic assembling machine for piston cooling nozzle

A piston cooling nozzle, automatic assembly machine technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of uneven quality, low efficiency, difficulty in automatic assembly of three parts, etc., and achieve high assembly accuracy , fast speed and obvious advantages in market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments and drawings.

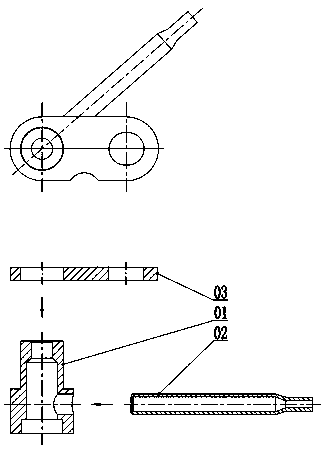

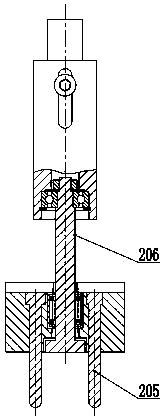

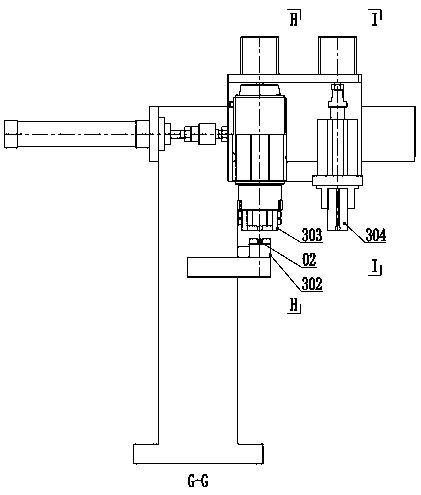

[0043] In the embodiment, such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, an automatic assembly machine for piston cooling nozzles includes: an assembly machine 1, for the pressure pipe assembly of valve body 01 and oil pipe 02, and the pressure plate assembly of valve body 01 and mounting piece 03; valve body positioner 2, It is used to transport valve body 01 and adjust the plug hole on the circumferential wall of valve body 01 to a specified angle; oil pipe positioner 3 is used to transport oil pipe 02 and align the plug end of oil pipe 02 with the plug of valve body 01 The connecting hole is convenient for pressure tube assembly; the installation piece positioner 4 is used to transport the installation piece 03, adjust the front and back of the installation piece 03, the front and back sides, and facilitate the installation of the pressure plate. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com