Rice hull powder master batch and preparation method thereof

A technology of rice husk powder and master batch, applied in the field of rice husk powder master batch and its preparation, can solve the problems of affecting the quality and size of finished products, reducing the qualified rate of products, waste of raw materials, etc., so as to ensure product quality and size, and accurately control Material ratio, the effect of reducing the loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

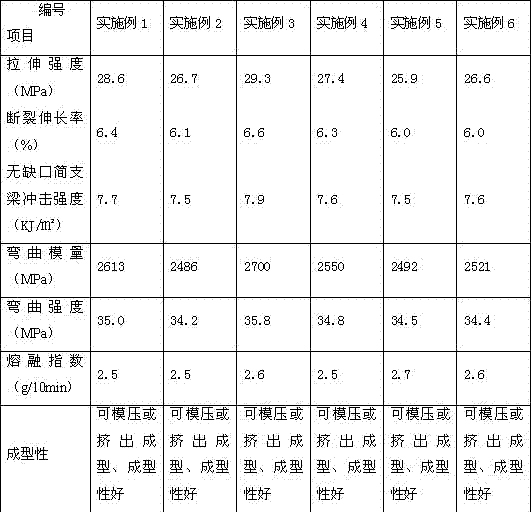

Examples

Embodiment 1

[0025] Rice husk powder masterbatch consists of 1Kg rice husk powder, 100g HDPE, 20g EVA, 50g plasticizer TBC, 10g antioxidant 100, 20g EVA wax, 2g ethanol aqueous solution with a mass concentration of 50%, 10g siloxane coupling agent Prepared.

[0026] The preparation method of the rice husk powder masterbatch of the present embodiment is as follows:

[0027] S1. Add 2 g of ethanol aqueous solution with a mass concentration of 50% dropwise into 10 g of siloxane coupling agent to fully hydrolyze the siloxane coupling agent, and set aside.

[0028] S2. Dry the rice husk powder with a diameter of 60 mesh first, take 1 kg of rice husk powder and place it in a high-speed mixer at a temperature of 120°C, mix and stir for 5 minutes, then add hydrolyzed siloxane coupling agent, and continue stirring for 10 minutes.

[0029] S3. Add 100g HDPE, 50g plasticizer TBC, 10g antioxidant 100, and 20g EVA to the high-speed mixer in sequence, and increase the working temperature of the high-sp...

Embodiment 2

[0032] Rice husk powder masterbatch consists of 1Kg rice husk powder, 95g PP, 15g LLDPE, 45g epoxy soybean oil, 8g antioxidant 100, 20g PE wax, 2g ethanol aqueous solution with a mass concentration of 50%, 10g siloxane coupling agent Prepared.

[0033] The preparation method of the rice husk powder masterbatch of the present embodiment is as follows:

[0034] S1. Add 2 g of 50% ethanol aqueous solution dropwise to 10 g of siloxane coupling agent to fully hydrolyze the siloxane coupling agent, and set aside.

[0035] S2. Dry the rice husk powder with a diameter of 50 mesh first, take 1 kg of rice husk powder and place it in a high-speed mixer at a temperature of 125° C., mix and stir for 6 minutes, then add hydrolyzed siloxane coupling agent, and continue stirring for 10 minutes.

[0036] S3. Add 95g PP, 45g epoxidized soybean oil, 8g antioxidant 100, and 15g LLDPE to the high-speed mixer in sequence, and increase the working temperature of the high-speed mixer to 160°C, and c...

Embodiment 3

[0039] Rice husk powder masterbatch is prepared from 1Kg rice husk powder, 108g PVC, 22g LLDPE, 55g epoxy soybean oil, 12g antioxidant 168, 21gPE wax, 2g ethanol aqueous solution with a mass concentration of 50%, and 12g siloxane coupling agent made.

[0040] The preparation method of the rice husk powder masterbatch of the present embodiment is as follows:

[0041] S1. Add 2 g of ethanol aqueous solution with a mass concentration of 50% dropwise into 12 g of siloxane coupling agent to fully hydrolyze the siloxane coupling agent, and set aside.

[0042] S2. Dry the rice husk powder with a diameter of 60 mesh first, take 1 kg of rice husk powder and place it in a high-speed mixer at a temperature of 115°C, mix and stir for 4 minutes, then add hydrolyzed siloxane coupling agent, and continue stirring for 13 minutes.

[0043] S3. Add 108g PVC, 55g epoxidized soybean oil, 12g antioxidant 168, and 22g LLDPE to the high-speed mixer in sequence, and increase the working temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com