Telmisartan tablet and preparation method thereof

A technology for telmisartan and tableting, which is applied in the field of telmisartan tablets and their preparation, can solve the problem that serious agglomeration or bed collapse is likely to occur, materials are easily adsorbed on the wall of a device, and telmisartan is not easy to mix. problems of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention provides a kind of preparation method of telmisartan tablet, wherein, described preparation method comprises:

[0019] 1) under the condition that solvent exists, telmisartan is mixed with acid-base regulator, makes telmisartan sodium salt;

[0020] 2) adding a binder to telmisartan sodium salt to prepare a slurry, adding a part of the filler, drying and granulating to obtain granules;

[0021] 3) Tablets are added after adding the remaining filler and lubricant to the granules to obtain telmisartan tablets; wherein,

[0022] The acid-base regulator includes at least sodium hydroxide.

[0023] In the present invention, telmisartan is first mixed with an acid-base regulator in the presence of a solvent, then a part of the filler is added after adding a binder therein, and dried and granulated to obtain granules, and further, to the above granules Add the filling agent of remaining part and all lubricants and mix tabletting, make the telmisartan in...

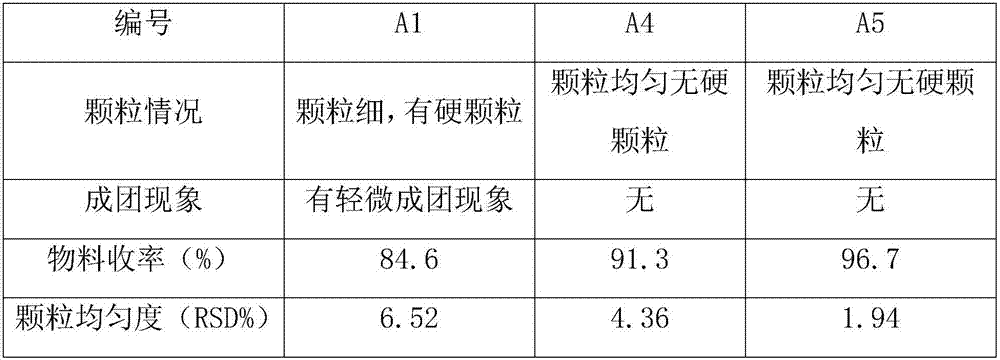

Embodiment 1

[0037] The sodium hydroxide 3.36g that weighed recipe quantity (in 1000 pieces) joins 150mL purified water, after stirring and dissolving, add meglumine 12g, after stirring and dissolving completely, add telmisartan raw material 40g, after stirring and dissolving completely, Finally, povidone was added, stirred and dissolved, and ultrasonically degassed to obtain a slurry. Weighed 122.24g of mannitol as a substrate and added it to a fluidized bed for granulation, plus 31.92g of mannitol, 12g of hydroxypropyl cellulose, and stearic acid. 1.68g of magnesium and 4.8g of talc powder were mixed and pressed into tablets to obtain Telmisartan Tablet A1. Among them, the parameters of the fluidized bed are: the spraying speed is 10r / min, the air inlet temperature is 50°C, the fan frequency is 30Hz, and the material temperature is controlled at about 40°C.

Embodiment 2

[0039] Prepare according to the preparation method of Example 1, the difference is that the spraying speed is 4r / min, the air inlet temperature is 60°C, and the material temperature is controlled at about 45°C to obtain Telmisartan Tablet A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com