Polyester composition, and preparation method thereof

A technology of composition and polyester, which is applied in the field of polymers to achieve the effect of improving toughness and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

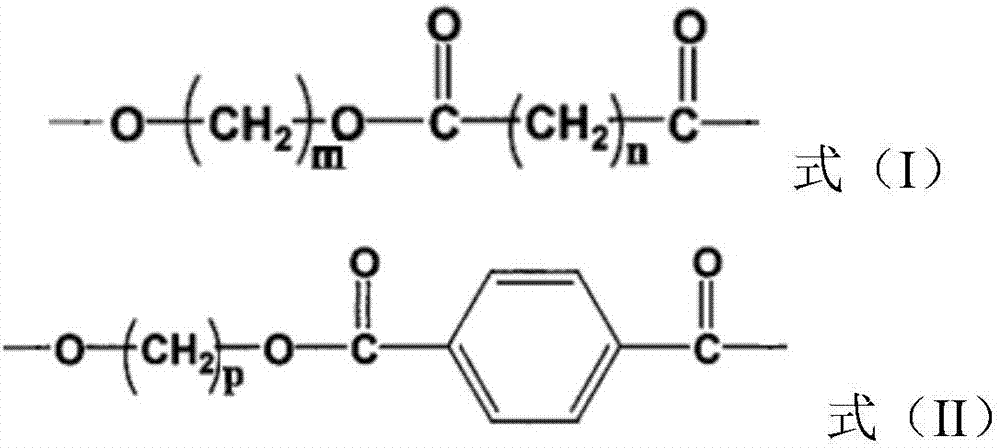

[0020] In the present invention, the aliphatic-aromatic copolyester can be at least one of random copolymers, alternating copolymers, block copolymers and graft copolymers, preferably random copolymers and / or block copolymers. In the present invention, the source of the aliphatic-aromatic copolyester is not particularly limited, and it can be obtained by conventional means in the field, for example, it can be obtained commercially, or it can be prepared according to the method disclosed in CN100429256C. Specifically, the preparation method of the aliphatic-aromatic copolyester may include the following steps: adding 1,4-butanediol, dimethyl benzoate and a catalyst as described in US11312373 to the reactor, Heat and stir under atmosphere until a clear solution is obtained. Subsequently, the temperature was raised to 160-220°C for reaction. When most of the distilled methanol in the system is removed, add succinic acid and raise the temperature to 180-240°C. Distill off most ...

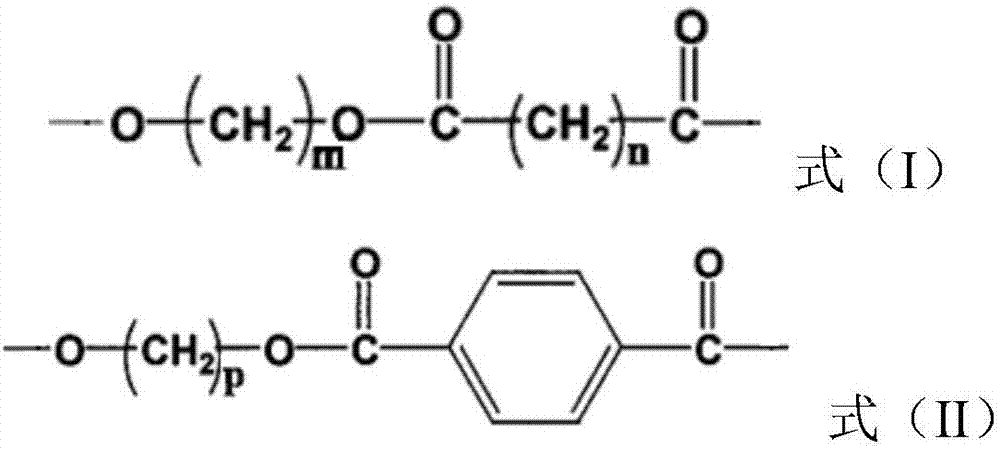

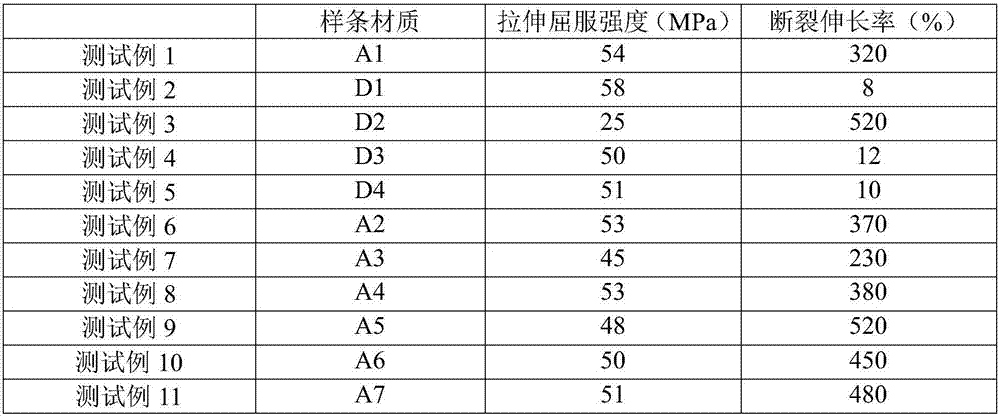

Embodiment 1

[0048] This example is used to illustrate the polyester composition provided by the present invention and its preparation method.

[0049] With 180g polybutylene terephthalate (purchased from DuPont Company, trade mark is Crastin SC164NC010, the same below), 20g butylene terephthalate-butylene succinate copolyester (weight average molecular weight is 100,000 , wherein, taking the total molar number of succinate butylene glycol repeating unit and terephthalate butylene glycol repeating unit as a basis, the content of terephthalate butylene glycol repeating unit 80 mol%) and 2g calcium carbonate are stirring Mixing under the condition of mixing, the stirring rate is 10rpm, and the time is 10min. The obtained mixture is extruded and granulated by a twin-screw extruder, the screw speed is controlled to be 10rpm, the screw torque is 20N*m, and the temperature of each section from the feed port to the extrusion port in the twin-screw extruder is 240 °C, 250°C, 260°C, 260°C, 265°C, ...

Embodiment 2

[0059] This example is used to illustrate the polyester composition provided by the present invention and its preparation method.

[0060] With 180g polybutylene terephthalate (purchased from DuPont, trade mark is Crastin SC164NC010), 20g butylene terephthalate-butylene succinate copolyester (weight-average molecular weight is 100,000, wherein, Taking the total molar number of butanediol succinate repeating unit and butanediol terephthalate repeating unit as a benchmark, the content of butanediol terephthalate repeating unit is 60 mole %) and 2g calcium carbonate under the condition of stirring Mixing, stirring at a rate of 10 rpm for 10 min. The obtained mixture is extruded and granulated by a twin-screw extruder, the screw speed is controlled to be 10rpm, the screw torque is 20N*m, and the temperature of each section from the feed port to the extrusion port in the twin-screw extruder is 240 °C, 250°C, 260°C, 260°C, 265°C, 260°C to prepare polyester composition A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com