Method for continuously extracting durene from coal-sourced aromatic hydrocarbon

A technology of durene and aromatics, applied in the field of durene preparation, which can solve the problems of low process safety, easy generation of static electricity, and high risk, and achieve the effect of simple and safe process operation, meeting market requirements, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

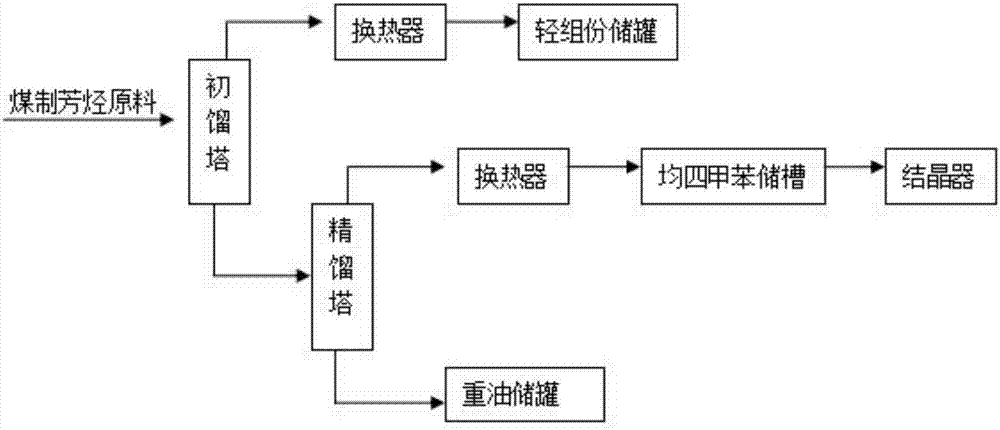

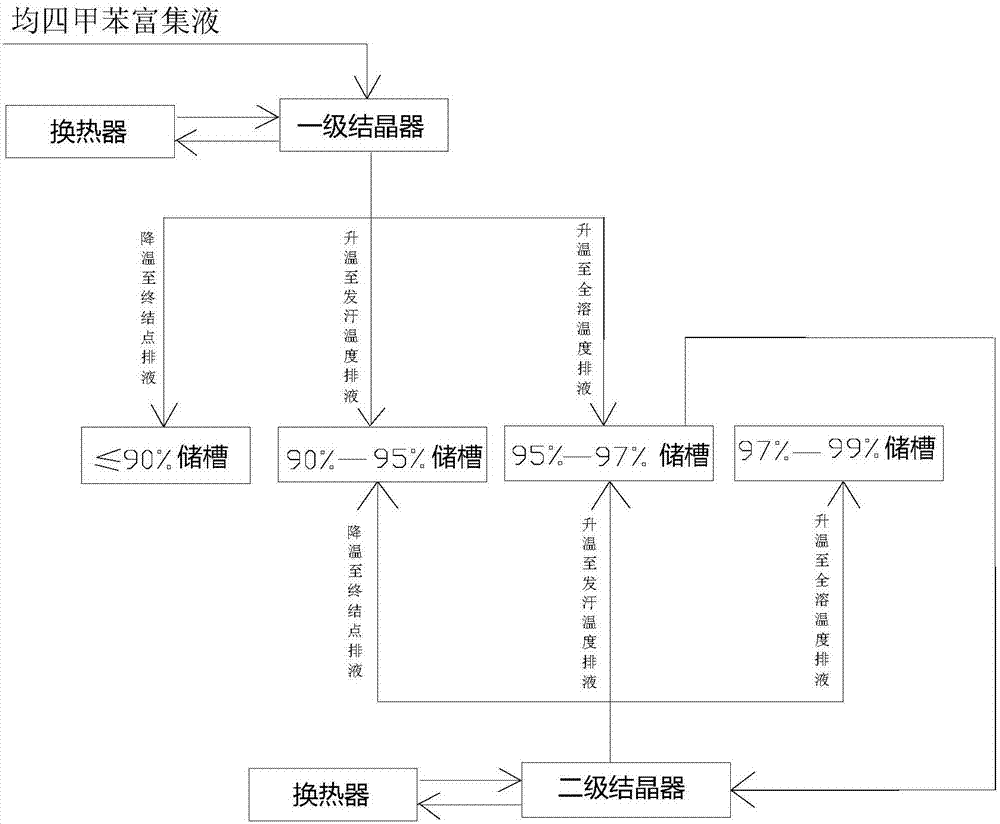

[0029] Coal-to-aromatic raw materials enter the primary distillation tower. The negative pressure in the primary distillation tower is 60KPa, and the temperature of the primary distillation tower is 190°C. Light components such as trimethylbenzene are separated from the top of the tower, and put into light components through a heat exchanger The component storage tank, the remaining liquid in the tower bottom enters the rectification tower, the negative pressure of the rectification tower is 60KPa, and the temperature of the tower bottom of the rectification tower is 200°C. The durene enriched liquid extracted from the top of the rectification tower is stored in the durene storage tank through a heat exchanger, and then sent to the first-stage crystallizer. The temperature is lowered to 50 °C at a cooling rate of 5 °C / h, and the uncrystallized The liquid is discharged into the 90% storage tank, and then the temperature is raised to 60°C at a constant temperature of 5°C / h and sw...

Embodiment 2

[0031] Coal-to-aromatic raw materials enter the initial distillation tower, the negative pressure in the initial distillation tower is 90KPa, and the temperature of the initial distillation tower is 160°C. Light components such as trimethylbenzene are separated from the top of the tower, and put into light components through a heat exchanger. The component storage tank, the remaining liquid in the bottom of the tower enters the rectification tower, the negative pressure of the rectification tower is 90KPa, and the temperature of the bottom of the rectification tower is 160°C. The durene enriched liquid extracted from the top of the rectification tower is stored in the durene storage tank through a heat exchanger, and then sent to the first-stage crystallizer. The temperature is lowered to 65°C at a cooling rate of 2°C / h, and the uncrystallized The liquid is discharged into the 90% storage tank, and then the temperature is raised to 77°C at a heating rate of 2°C / h to sweat at a ...

Embodiment 3

[0033] Coal-to-aromatic raw materials enter the initial distillation tower, the negative pressure in the initial distillation tower is 40KPa, and the temperature of the initial distillation tower is 200°C. Light components such as trimethylbenzene are separated from the top of the tower, and put into light components through a heat exchanger. Component storage tank, the remaining liquid in the bottom of the tower enters the rectification tower, the negative pressure of the rectification tower is 40KPa, and the temperature of the bottom of the rectification tower is 200°C. The durene enriched liquid extracted from the top of the rectification tower is stored in the durene storage tank through a heat exchanger, and then sent to the primary crystallizer. The temperature is lowered to 60°C at a cooling rate of 4°C / h, and the uncrystallized The liquid is discharged into the 90% storage tank, and then the temperature is raised to 70°C at a rate of 3°C / h, and the temperature is sweate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com