Pre-joint-coating method for welded junction of steel pipe

A welding joint and steel pipe technology, which is applied in welding equipment, tubular objects, arc welding equipment, etc., can solve the problem of high difficulty in anti-corrosion repairing operations, and achieve the effects of reducing safety and environmental protection risks, ensuring anti-corrosion performance, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiment of the present application provides a method for pre-filling welded joints of steel pipes, which solves the technical problem of high difficulty in the internal anti-corrosion repairing of steel pipes in the prior art, reduces the repairing process and difficulty, and prolongs the life cycle of pipelines. The technical effect of reducing the safety and environmental protection risks caused by pipeline corrosion and leakage.

[0035] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

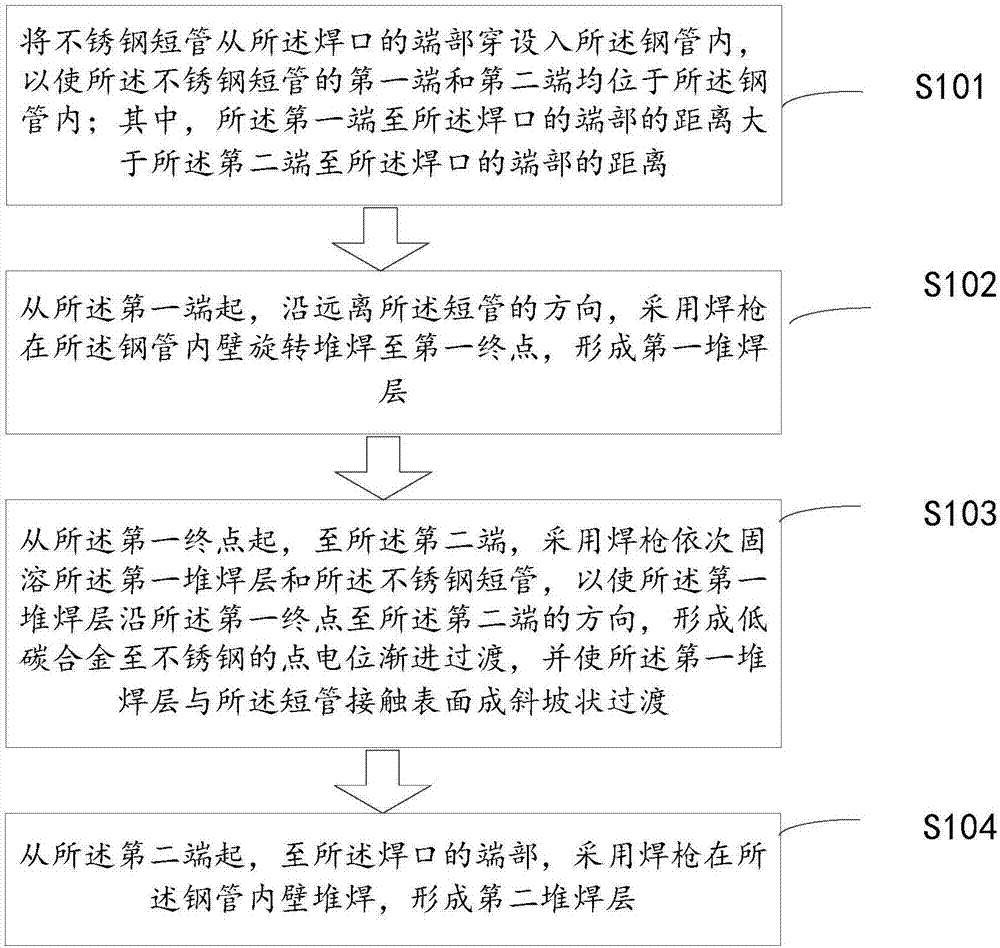

[0036] This application provides a method for pre-filling welded joints of steel pipes, including:

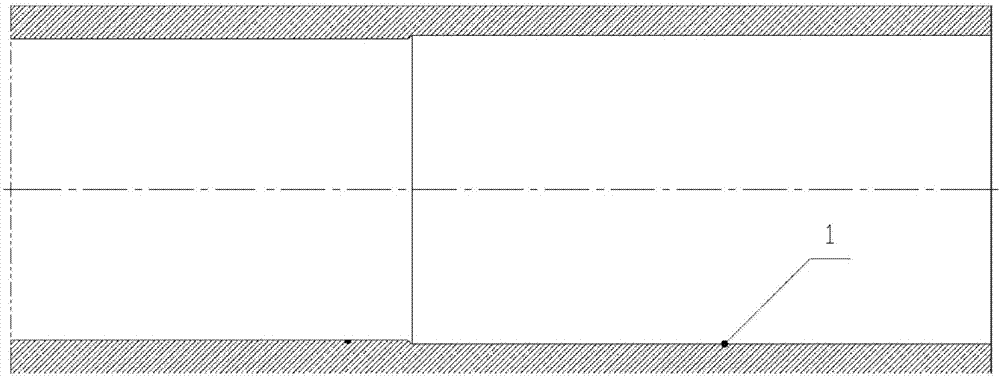

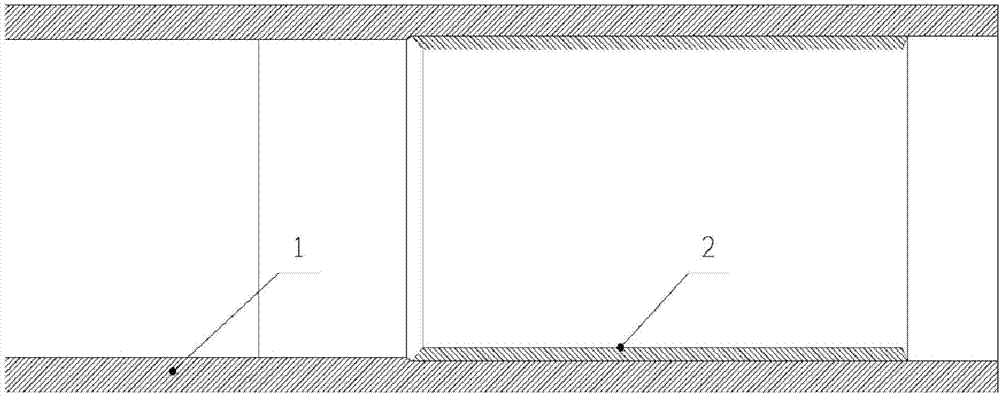

[0037] The short stainless steel pipe is inserted into the steel pipe from the end of the welding port, so that the first end and the second end of the short stainless steel pipe are located in the steel pipe; wherein, the first end to The distance from the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com