Ultrasonic vibration auxiliary micro-bulging device and method for thin-wall complex-curved-surface micro-structure component

A technology of ultrasonic vibration and complex curved surface, which is applied in the field of material forming, can solve the problems such as the inability to manufacture microstructural components in the existing process, and achieve the effects of good consistency, increasing the bulging forming limit, and increasing the elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

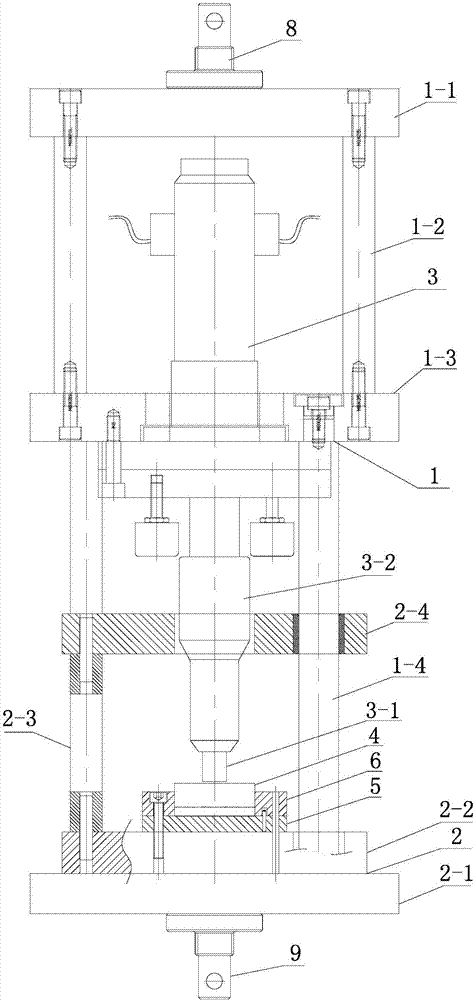

[0018] see figure 1 Explain that the ultrasonic vibration-assisted micro-bulging device for thin-walled complex curved surface microstructure components includes an upper connecting seat 1, a lower connecting seat 2, an ultrasonic vibration source 3, a punch 4, a die 5, and a pressure plate 6;

[0019] The ultrasonic vibration source 3 is installed on the upper connecting seat 1, the upper connecting seat 1 is vertically slidably installed on the lower connecting seat 2, the die 5 is installed on the lower connecting seat 2, and the binder plate 6 is connected with the die 5 and between them Used to place the blank plate to be formed, the punch 4 is driven by the punch machine, the punch 4 is slidably set in the inner hole of the pressing plate 6, and the lower surface of the punch 4 has an array of raised microstructures 4-1, The upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com