Dust treatment system for dusting workshop

A dust treatment and workshop technology, which is applied to sound equipment, dispersed particle filtration, instruments, etc., can solve the problems of difficulty in meeting emission standards, high equipment investment costs, shortening the service life of filter cartridges, etc., and achieve ideal noise reduction and noise reduction effects. , Improve the filter effect, improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

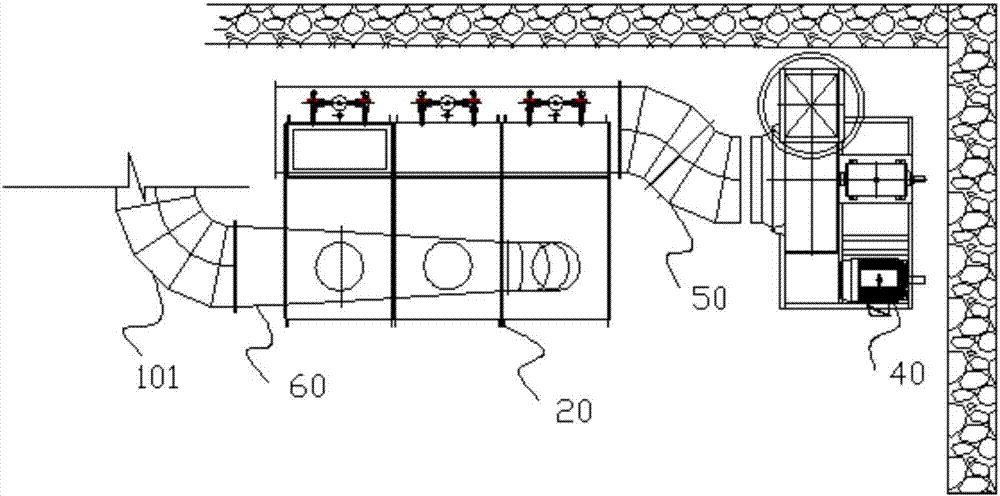

[0056] Embodiment: a kind of dust processing system for powder spraying workshop, such as Figure 1.1 to Figure 8 As shown, it includes a dust collection device 10, a horizontal filter cartridge dust collector 20 and a smoke exhaust device 30 arranged in sequence according to the dust flow direction, and an induced draft fan 40 is also provided on the flow channel of the dust; the dust collection device and The horizontal filter cartridge dust collector is connected, and the horizontal filter cartridge dust collector is connected to the smoke exhaust device;

[0057] The horizontal filter cartridge type dust collector is provided with at least one dust processing bin, each dust processing bin includes a first bracket 201, a bin body 202, an exhaust gas inlet 203, a clean gas outlet 204 and a dust collecting hopper 205 , the bin body is installed on the first bracket, the exhaust gas inlet is located at the upper end of the bin body, the clean gas outlet is located at the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com