Device and method for cogeneration of ethylene glycol by coal pyrolysis production semicoke technique

A technology of coal pyrolysis and ethylene glycol, which is applied in gasification process, chemical instruments and methods, coke oven, etc., can solve the problems of comprehensive utilization of pyrolysis tail gas that needs further research and development, few mature technologies, and high operating costs, and achieves Considerable economic benefits, the effect of solving dust pollution and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

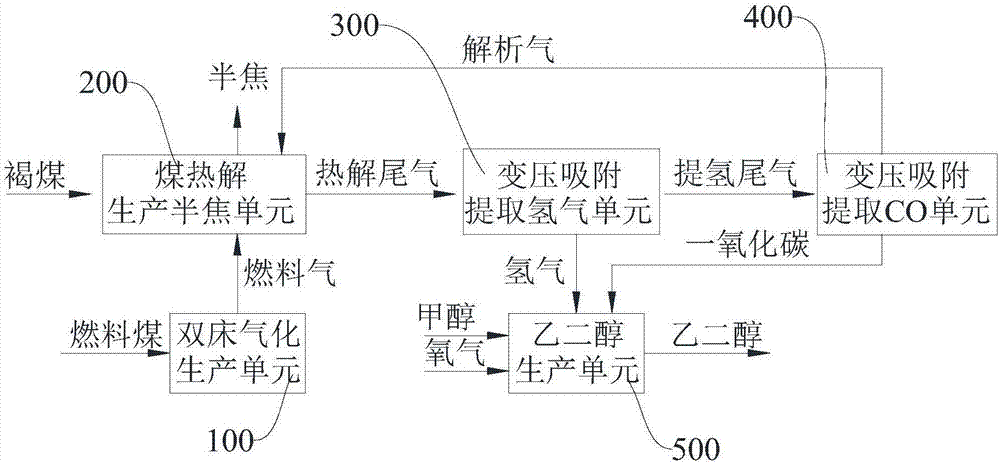

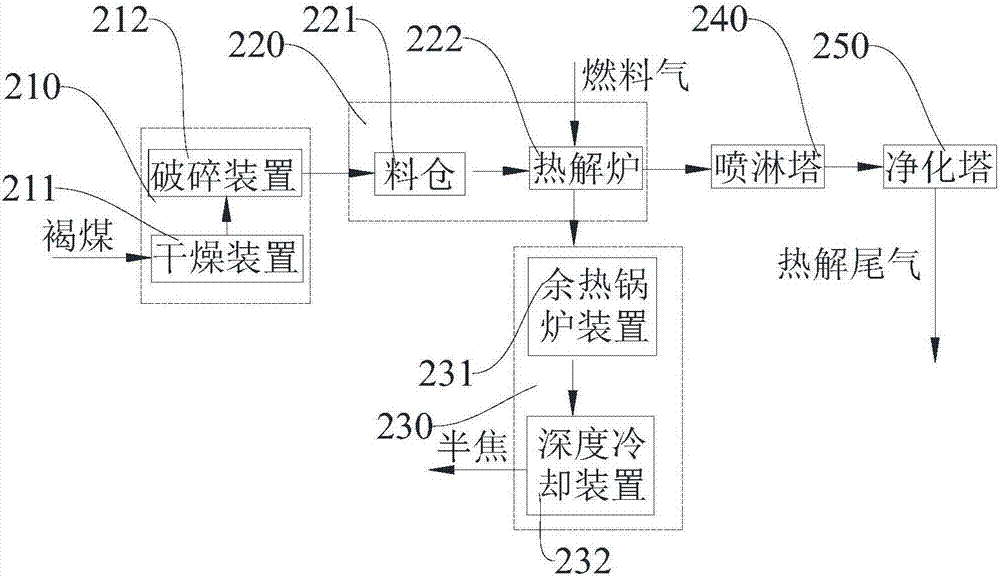

[0036] figure 1 The flow chart of the device for producing semi-coke and co-producing ethylene glycol by pyrolysis of coal provided in this example. see figure 1, in this embodiment, the coal pyrolysis production semi-coke process co-production of ethylene glycol device includes a twin-bed gasification production unit 100, coal pyrolysis semi-coke production unit 200, pressure swing adsorption hydrogen extraction unit 300, pressure swing adsorption extraction A carbon monoxide unit 400 and an ethylene glycol production unit 500 . The twin-bed gasification production unit 100 provides thermal energy for the coal pyrolysis semi-coke production unit 200 to produce semi-coke and obtain by-products, which are first subjected to pressure swing adsorption hydrogen extraction unit 300 to extract hydrogen, and then pressure swing adsorption The carbon monoxide extraction unit 400 extracts carbon monoxide, and passes the carbon monoxide and hydrogen into the ethylene glycol production...

Embodiment 2

[0076] This embodiment also provides a method for co-production of ethylene glycol by coal pyrolysis to produce semi-coke process, which is carried out by using the coal pyrolysis to produce semi-coke process co-production of ethylene glycol device provided in Example 1, and the content of embodiment 1 is the same Applicable to this embodiment, the method includes the following steps:

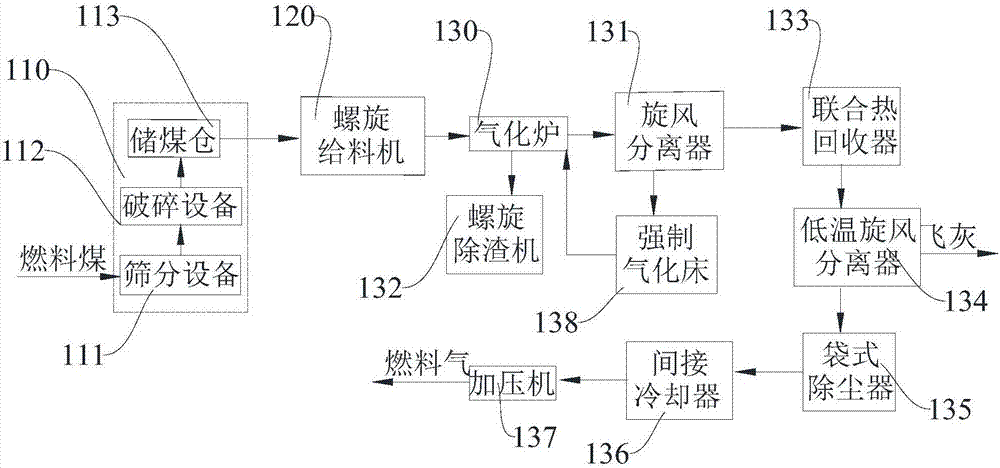

[0077] S1. Process the fuel coal through the gasifier 130 of the twin-bed gasification production unit 100 to obtain fuel gas; that is, the fuel coal is firstly screened through a screening device to remove lump coal with a particle size greater than 30mm, and the lump coal is additionally Use: The pulverized coal (with a particle size below 30mm) that has passed the primary screening is transported to the crushing equipment 112, and after being crushed to a size below 8mm, it is transported to the coal storage bin 113 by a belt conveyor.

[0078] The coal in the coal storage bunker 113 is fed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com