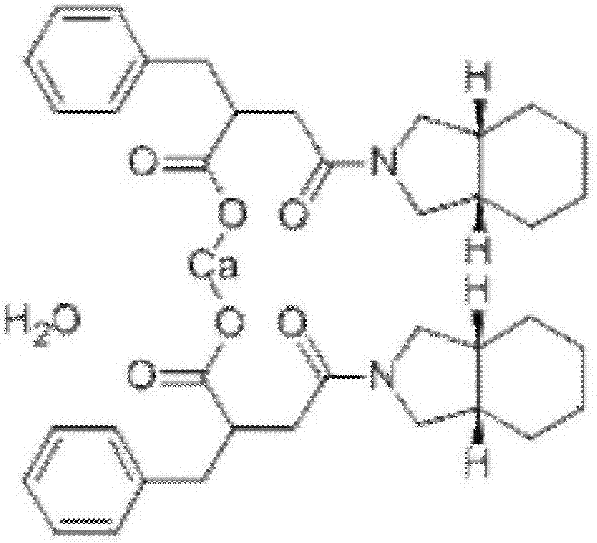

Preparation method of mitiglinide calcium

A technology of mitiglinide calcium and benzyl succinic acid, which is applied in the field of pharmacy, can solve the problems of long steps, lack of purity, and short steps, and achieve the effects of reducing related substances, saving reagents, and shortening reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] Step 1: Synthesis of benzylidene succinic acid: Add 480 grams of anhydrous methanol and 65 grams of sodium methylate into the reaction tank to stir and dissolve, add 450 grams of diethyl succinate, heat to reflux, and drop 100 grams of benzene Formaldehyde, reflux for not less than 1 hour, then distill methanol, slowly add 480 grams of 40% sodium hydroxide solution, add drinking water, dichloromethane, stir for 30-60 minutes, add concentrated hydrochloric acid dropwise to adjust the pH value to 2- 3. Precipitate the product and dry it.

[0067] The molar ratio of diethyl succinate and benzaldehyde to the above reaction is 5.0.

[0068] Step 2: Synthesis of benzyl succinic acid: dissolve benzylidene succinic acid with 4.8 times the absolute ethanol of benzylidene succinic acid, add 3% activated carbon for decolorization for 2 hours, filter the activated carbon, add to the reaction tank and stir, pass through Nitrogen, exhaust the air, add 25 grams of 10% palladium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

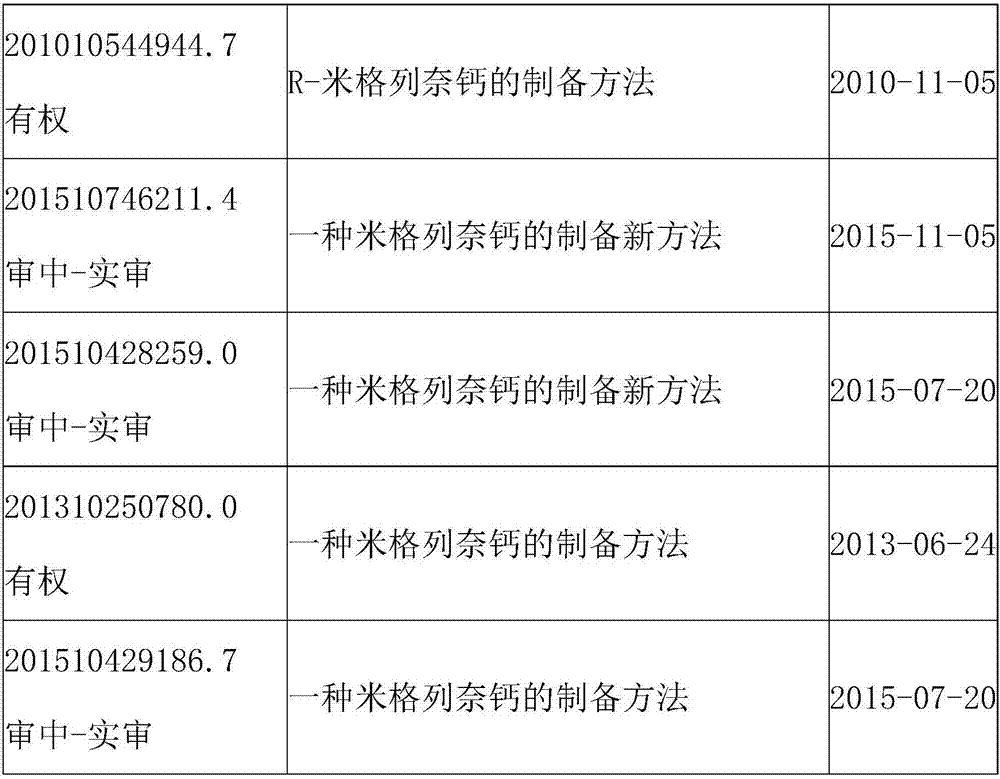

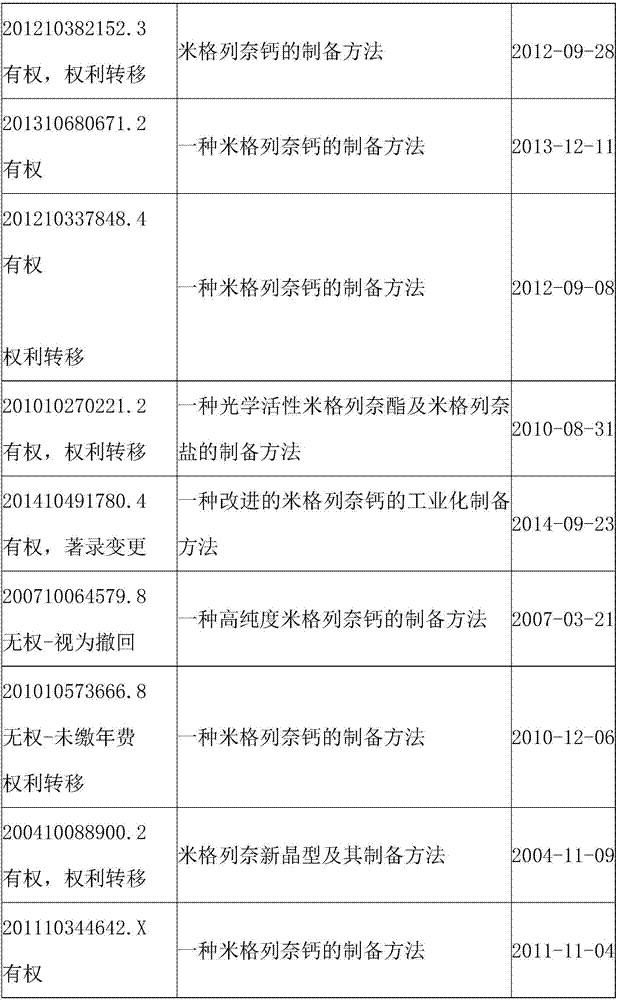

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com