Electrode for preparing cover glass

A cover glass and electrode technology, applied in glass furnace equipment, glass manufacturing equipment, electric furnace, etc., can solve the problems of shortened life, increased Mo loss, and easy oxidation of molybdenum electrodes, so as to prolong the service life and increase the compactness , high antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

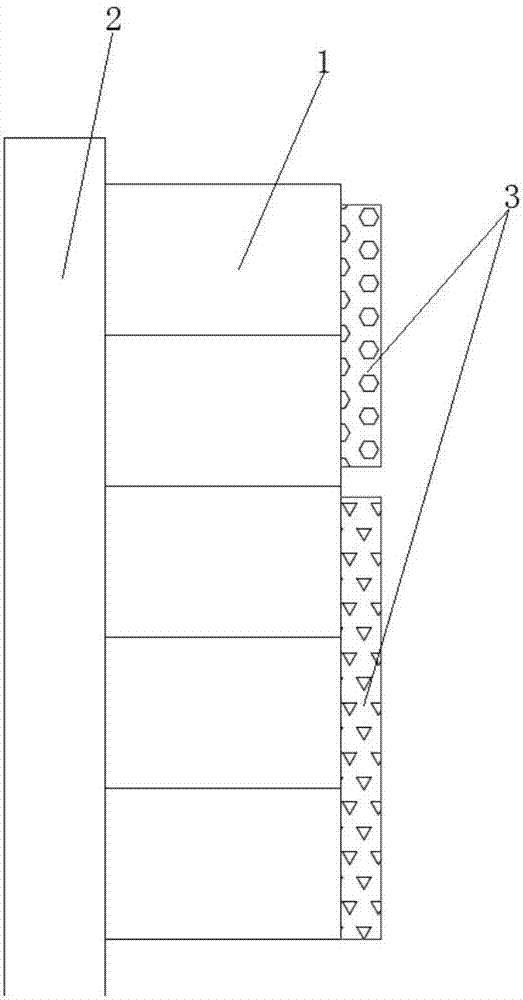

Image

Examples

Embodiment 1

[0024] With 96% tin dioxide SnO 2 as the base material, and in tin dioxide SnO 2 Add 0.8% Sb in 2 o 3 ; 1.8% ZrO 2 ; 0.4% CuO to make an electrode with a length of 480 mm, a width of 95 mm, and a height of 145 mm.

Embodiment 2

[0026] With 96.3% tin dioxide SnO 2 as the base material, and in tin dioxide SnO 2 Add 1% Sb in 2 o 3 ; 1.9% ZrO 2 ; 0.4% CuO to make an electrode with a length of 500 mm, a width of 100 mm and a height of 150 mm.

Embodiment 3

[0028] With 96.5% tin dioxide SnO 2 as the base material, and in tin dioxide SnO 2 Add 1.1% Sb in 2 o 3 ; 2.0% ZrO 2 ; 0.5% CuO to make an electrode with a length of 520 mm, a width of 105 mm, and a height of 155 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com