Enhanced denitration monolithic catalyst coating slurry, and preparation method and application thereof

A kind of integral catalyst and catalyst technology, which is applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. It can solve the problems of affecting catalyst activity, large amount of addition, and not very firm adsorption, etc., to achieve benefit Stable storage, extended stable period, and the effect of adding a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of Hyperdispersant

[0037] (1-1) Add 75ml of cyclohexanone, 2.8ml of styrene and 2.5g of maleic anhydride in the four-necked flask equipped with stirring, reflux condensation, thermometer and nitrogen device, and add 0.005g after three times of vacuuming and nitrogen replacement The benzoyl peroxide was heated to 110 °C in a water bath for 4 hours and then cooled to room temperature. Then adjust the pH value to 7-8 with 30% sodium hydroxide to obtain a light yellow slightly viscous liquid, which is a copolymer of styrene and maleic anhydride, which is denoted as hyperdispersant A for later use.

[0038] (1-2) In the four-necked flask equipped with stirrer, reflux condenser, dropping funnel and thermometer, add 80ml of deionized water, 0.4g of emulsifier sodium lauryl sulfate, 20g of butyl acrylate and 30g of Methyl methacrylate, stirred and dissolved, heated to 80°C in a water bath, 13ml of acrylic acid and an aqueous solution containing 0.48g o...

Embodiment 2

[0043] Example 2: Catalyst Coating Suspension Slurry Preparation

[0044] (a) Solution preparation: weigh the catalyst active component V 2 O 5 The precursor salt ammonium metavanadate 2.30g and the catalyst promoter WO 3 20.2 g of the precursor salt of ammonium paratungstate was dissolved in 120 ml of deionized water at 80-90 °C, and cooled to room temperature to obtain mixed solution A.

[0045] (b) Pre-dispersion of hyperdispersant: 0.9 g of hyperdispersant A and 0.09 g of n-hexanol are uniformly dispersed in mixed solution A under stirring to obtain mixed solution B.

[0046] (c) ball milling liquid preparation: weigh 5 g of ethanolamine and 40 g of silica sol with a mass concentration of 25%, slowly add to the mixed solution B obtained in step (b) under stirring, and mix thoroughly to obtain ball milling mixed liquid C.

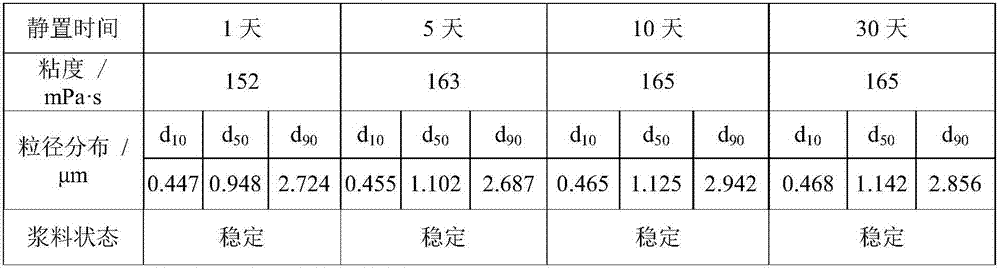

[0047] (d) Ball milling slurry: weigh 90 g of anatase TiO 2 Place in a ball-milling tank, slowly add the ball-milling mixed solution C obtained in s...

Embodiment 3

[0051] Example 3: Catalyst Coating Suspension Slurry Preparation

[0052] (a) Solution preparation: weigh the catalyst active component V 2 O 5 The precursor salt ammonium metavanadate 10.0g and the catalyst promoter WO 3 50.0 g of the precursor salt of ammonium paratungstate was dissolved in 440 ml of deionized water at 80-90 °C, cooled to room temperature, and mixed solution A was obtained.

[0053] (b) Pre-dispersion of hyperdispersant: 7.0 g of hyperdispersant B and 0.7 g of n-hexanol are uniformly dispersed in mixed solution A under stirring to obtain mixed solution B.

[0054] (c) ball milling liquid preparation: weigh 10 g of ethanolamine and 80 g of silica sol with a mass concentration of 25%, slowly add to the mixed solution B obtained in step (b) under stirring, and mix thoroughly to obtain ball milling mixed liquid C.

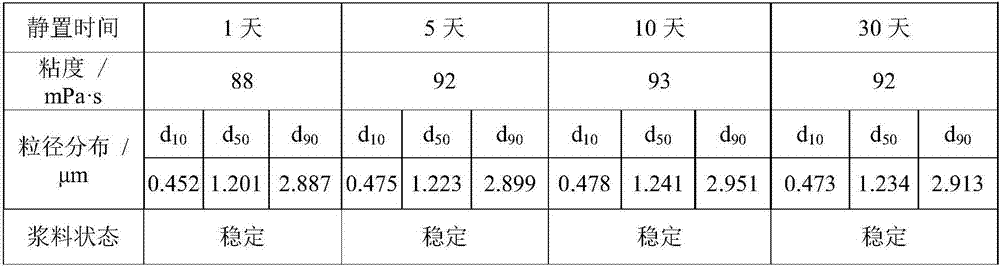

[0055] (d) Ball milling slurry: weigh 150 g of anatase TiO 2 Place in a ball-milling tank, slowly add the ball-milling mixed solution C obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| F | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com