Preparation method of alpha-phase silicon nitride powder

A technology based on silicon nitride powder and silicon tetrachloride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of unsuitability for large-scale production, strict raw material requirements, high cost, etc. control, uniform grain size distribution, and the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1, preparation of α-phase silicon nitride powder

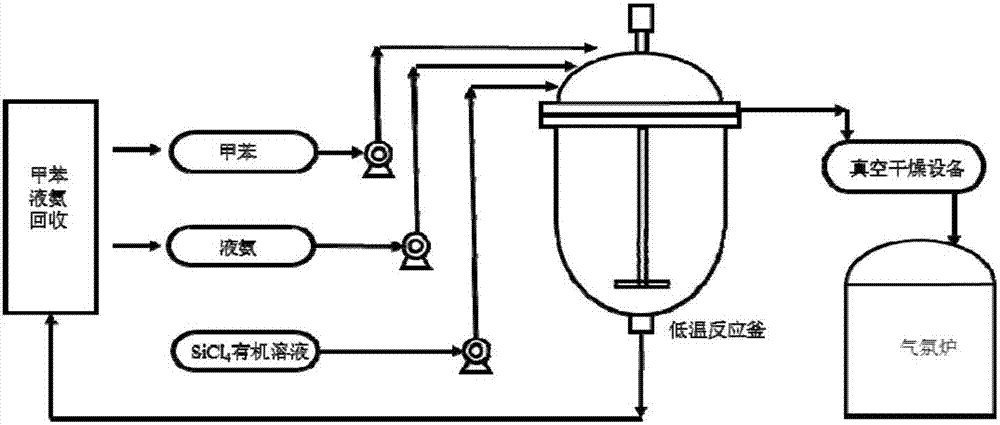

[0051] according to figure 2 The flow chart shown in the preparation of α-phase silicon nitride powder, the specific steps are as follows:

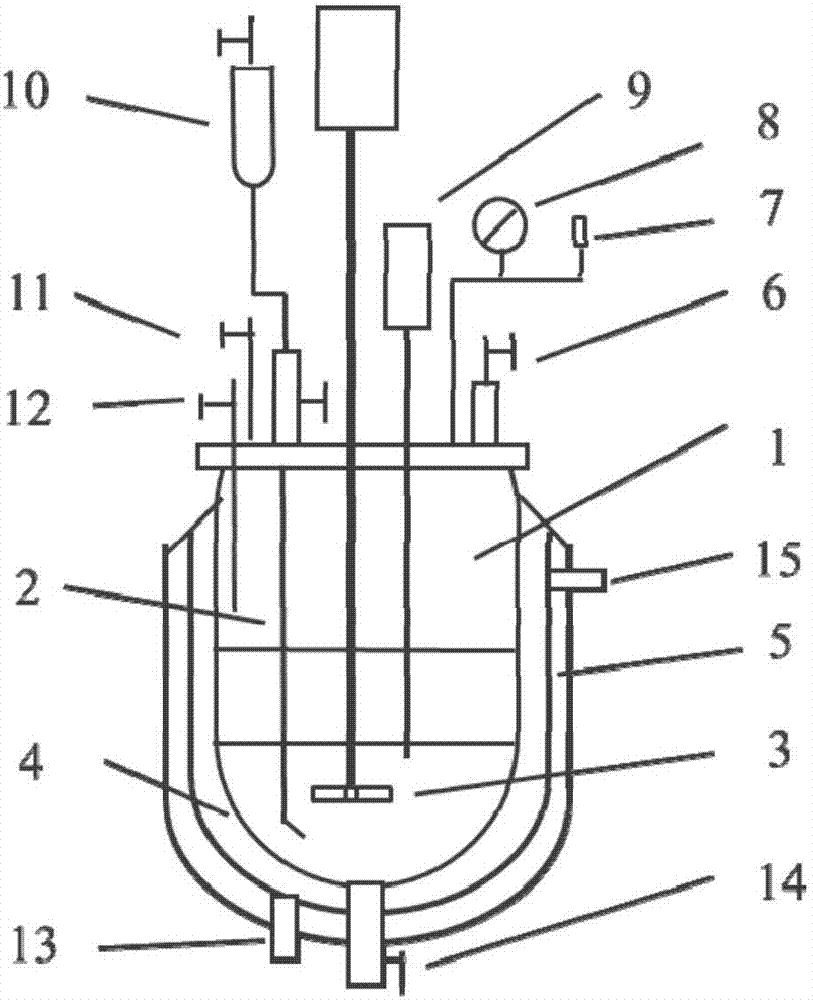

[0052] (1) Control the temperature in the reactor to be -45°C, place a mixed solution of 200 volumes of toluene and 200 volumes of xylene and 100 volumes of liquid ammonia in figure 1 In the reaction kettle shown, let it stand for stratification; mix 5 volumes of silicon tetrachloride with 95 volumes of toluene, put the mouth of the silicon tetrachloride feeding tube into the toluene layer in the reaction kettle, and pass it into the feeding tank The mixture of silicon tetrachloride and toluene was injected into the toluene layer by nitrogen pressure, and the feeding rate was controlled at 3mL / min, so that silicon tetrachloride diffused to the liquid phase interface of toluene and liquid ammonia, and the stirring paddle was continuously stirred. The rotation speed is 70 ...

Embodiment 2

[0056] Example 2, preparation of α-phase silicon nitride powder

[0057] according to figure 2 The flow chart shown in the preparation of α-phase silicon nitride powder, the specific steps are as follows:

[0058] (1) Control the temperature in the reactor to be -50°C, place a mixed solution of 300 volumes of toluene and 100 volumes of xylene and 100 volumes of liquid ammonia in figure 1 In the reaction kettle shown, let it stand for stratification; mix 10 volumes of silicon tetrachloride with 90 volumes of toluene, put the mouth of the silicon tetrachloride feeding tube into the toluene layer in the reaction kettle, and pass it into the feeding tank The mixed solution of silicon tetrachloride and toluene was injected into the toluene layer by means of nitrogen pressure, and the feeding rate was controlled at 5mL / min, so that the silicon tetrachloride diffused to the liquid phase interface of toluene and liquid ammonia, and the stirring paddle continued to stir. The rotatio...

Embodiment 3

[0062] Example 3, preparation of α-phase silicon nitride powder

[0063] according to figure 2 The flow chart shown in the preparation of α-phase silicon nitride powder, the specific steps are as follows:

[0064] (1) Control the temperature in the reactor to be -55°C, place 400 volumes of toluene and 100 volumes of liquid ammonia in figure 1 In the reaction kettle shown, let it stand for stratification; mix 10 volumes of silicon tetrachloride with 90 volumes of toluene, put the mouth of the silicon tetrachloride feeding tube into the toluene layer in the reaction kettle, and pass it into the feeding tank The mixed solution of silicon tetrachloride and toluene was injected into the toluene layer by means of nitrogen pressure, and the feeding rate was controlled at 5mL / min, so that the silicon tetrachloride diffused to the liquid phase interface of toluene and liquid ammonia, and the stirring paddle continued to stir. The rotation speed is 100 rpm, silicon tetrachloride and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com