Integrated device for catalytic-cracking-flue-gas desulfurization, denitration, dust removing and acid mist removing and method

A catalytic cracking, desulfurization and denitrification technology, applied in chemical instruments and methods, combined devices, gas treatment, etc., can solve problems such as non-compliance with emission standards, nitrogen oxides failing to meet technical guarantee value indicators, and soot concentration failing to meet emission standards, etc. , to achieve the effect of solving tailing and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

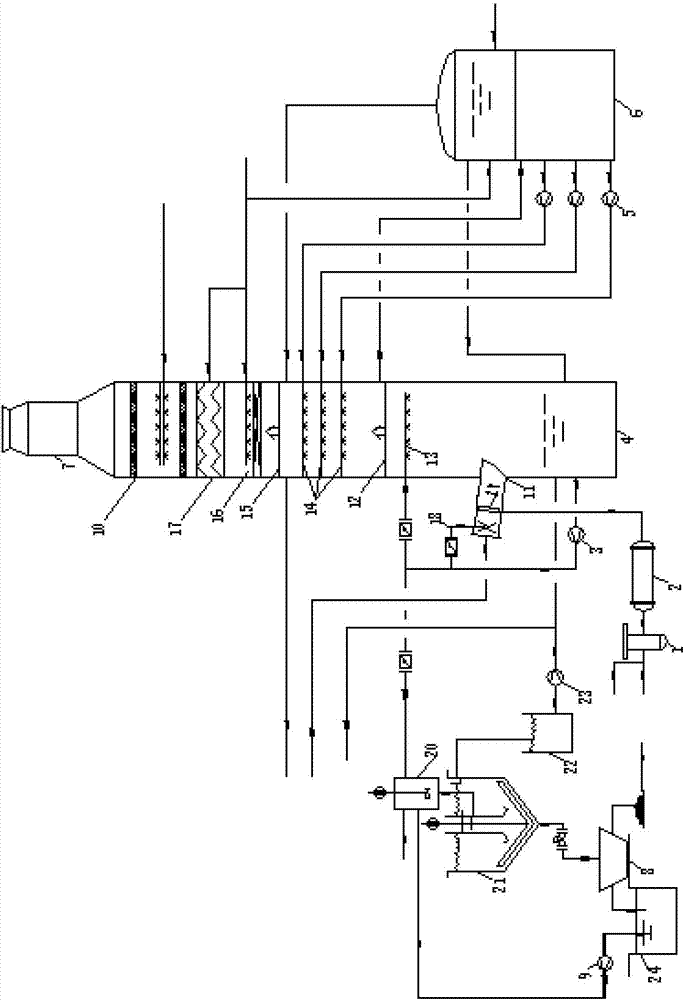

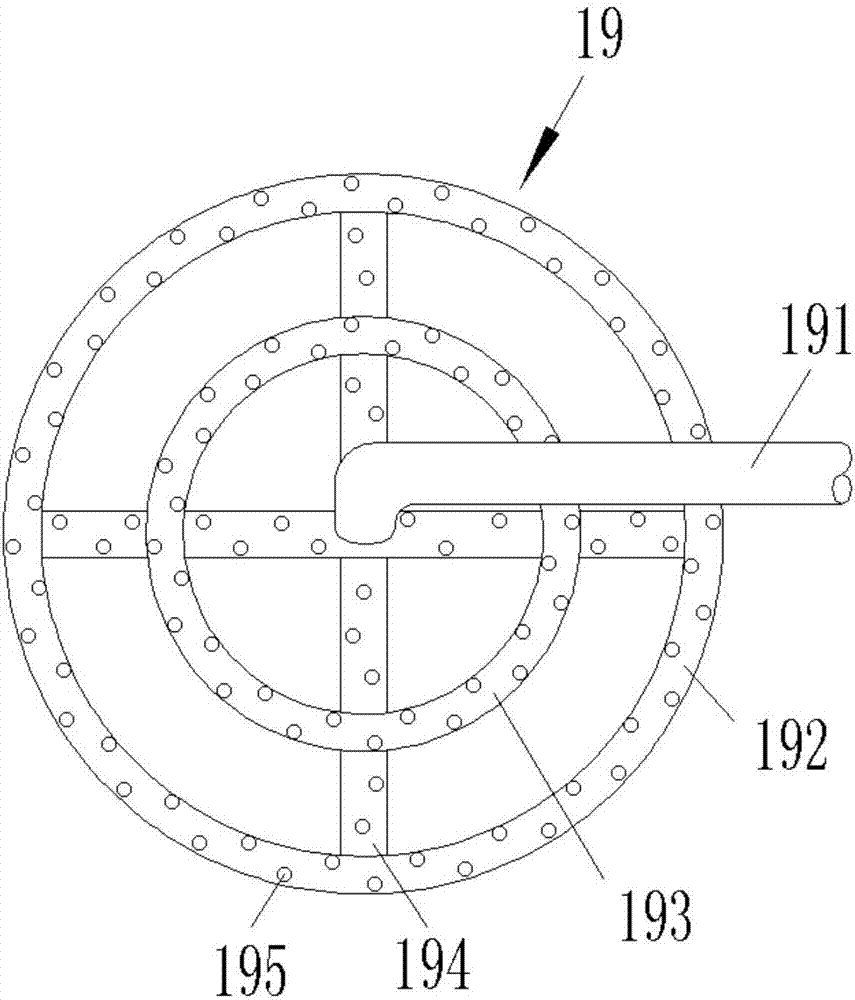

[0030] like figure 1 As shown, an integrated device for catalytic cracking flue gas desulfurization, denitration, dust removal and acid mist removal includes an ozone generator 2 and a desulfurization tower 4; the desulfurization tower 4 is provided with an inclined flue 11 and a chimney 7, and the inclined flue 11 and the chimney 7, according to the flue gas flow direction in the desulfurization tower 4, the quenching spray pipe 18, the ozone gas distribution plate 19, the accident spray pipe 13, the first air lift cap 12, several empty tower spray pipes 14, the first The two-liter air cap 15, the ammonia demister 16, the roof ridge demister 17 and the wire mesh demister 10; the ozone generator 2 is communicated with the ozone air distribution plate 19 through a pipeline.

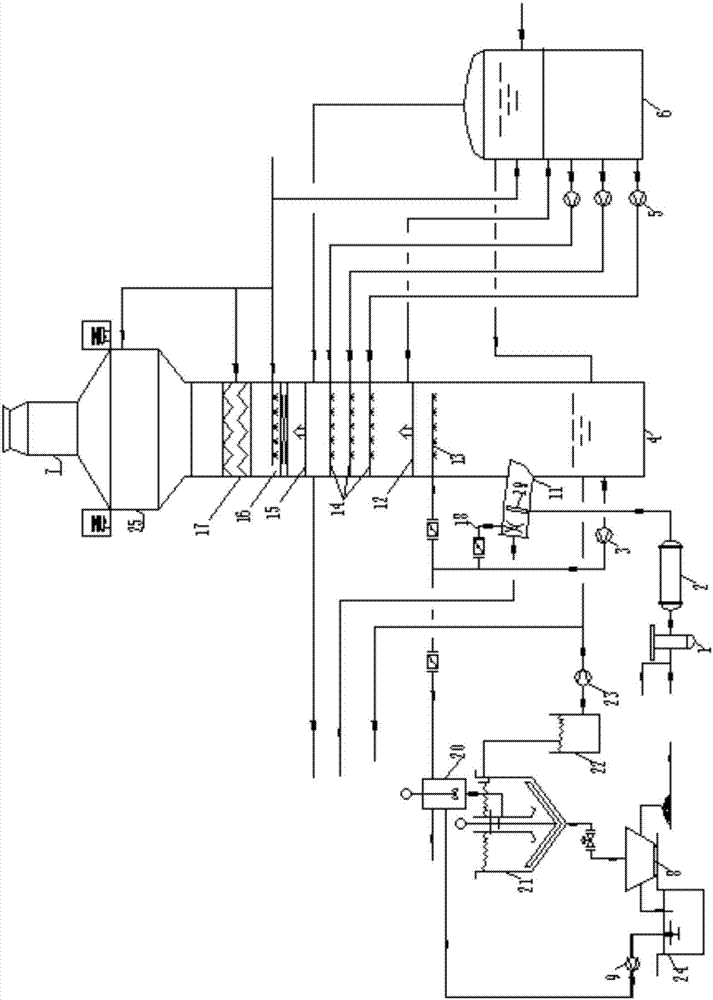

[0031] like figure 2 As shown, the acid mist content of the flue gas at the inlet of the wire mesh demister 10 is > 70 mg / Nm 3 , the wire mesh demister 10 is replaced with an electric demister 25.

[0...

Embodiment 2

[0059] A method for treating flue gas from catalytic cracking using the device of Example 1, comprising the following steps: flue gas with a temperature ≤ 200°C and a humidity of 7% to 10% from the waste heat boiler of the catalytic cracking unit, the concentration of sulfur dioxide in the flue gas is between 1000~2000mg / Nm 3 、NOx content 100~350mg / Nm 3 And the concentration of catalyst dust is 30~600mg / Nm 3 The flue gas is cooled through the quenching spray pipe 18, and then the ozone desulfurization is carried out through the ozone gas distribution pan 19, and then through the accident spray pipe 13, the first gas-raising cap 12, several empty tower spray pipes 14, the second gas-raising Cap 15, ammonia demister 16, roof ridge demister 17 and wire mesh demister 10 or electric demister 25 remove ammonia mist, water mist and sulfuric acid mist.

[0060] Specifically, the reaction contact time of the flue gas for ozone desulfurization is 1 to 2 seconds, the ammonia demister 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com