High-rate graphite negative electrode material, preparation method thereof and lithium ion battery

A graphite negative electrode, high-rate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor fast charging ability, achieve the effect of improving fluidity, increasing layer spacing, and increasing lithium storage junctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

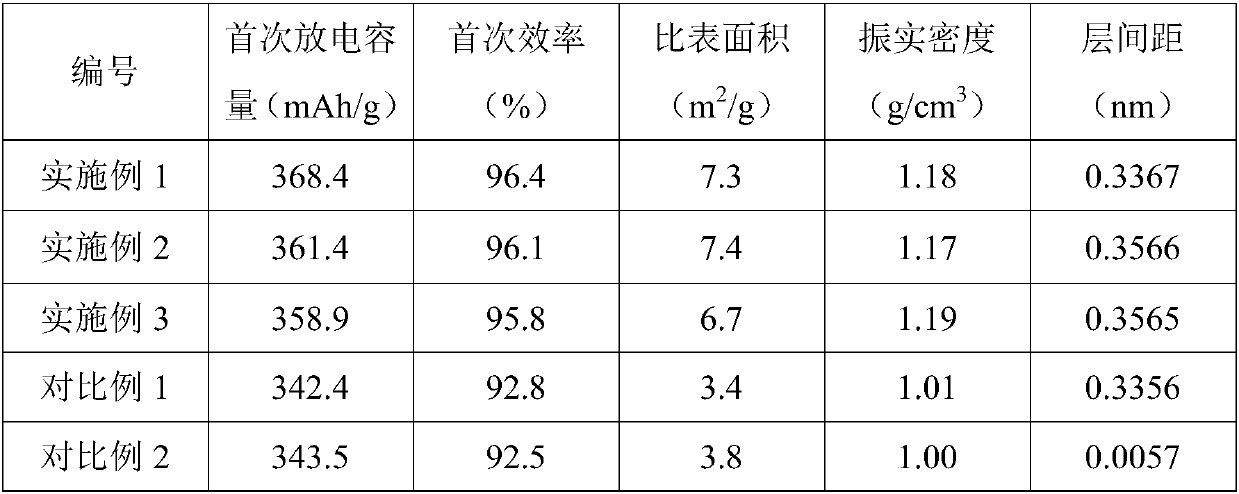

Examples

Embodiment 1

[0033] The high-magnification graphite negative electrode material of this embodiment includes a graphite core and a hard carbon material layer doped on the surface of the graphite core, the hard carbon material layer is doped with lithium nitride, and the thickness of the hard carbon material layer is 100 nm.

[0034] The preparation method of the high-magnification graphite negative electrode material of the present embodiment adopts the following steps to prepare:

[0035] 1) Add 5g of phenolic resin to 500mL of ethanol, disperse evenly, add 0.5g of passivated lithium powder, and disperse evenly again to obtain the coating solution; then add 100g of natural graphite to the coating solution and mix evenly, and prepare the precursor by spray drying body particles;

[0036] 2) Under a nitrogen atmosphere, the precursor particles are reacted with nitrogen gas by EDM to prepare a lithium nitride doped precursor; the power of the electric spark is 750W, the voltage is 100V, and t...

Embodiment 2

[0040] The high-magnification graphite negative electrode material of this embodiment includes a graphite core and a hard carbon material layer doped on the surface of the graphite core, the hard carbon material layer is doped with lithium nitride and element S, and the thickness of the hard carbon material layer is 300nm .

[0041] The preparation method of the high-magnification graphite negative electrode material of the present embodiment adopts the following steps to prepare:

[0042] 1) Add 1g of epoxy resin to 500mL of ethanol, disperse evenly, add 0.1g of passivated lithium powder, and disperse evenly again to obtain the coating solution; then add 100g of natural graphite to the coating solution and mix evenly, and prepare by spray drying Precursor particles;

[0043] 2) Under a nitrogen atmosphere, the precursor particles are reacted with nitrogen gas by EDM to prepare a lithium nitride doped precursor; the power of the electric spark is 600W, the voltage is 80V, and t...

Embodiment 3

[0047] The high-magnification graphite negative electrode material in this embodiment includes a graphite core and a hard carbon material layer doped on the surface of the graphite core, the hard carbon material layer is doped with lithium nitride, and the thickness of the hard carbon material layer is 500 nm.

[0048] The preparation method of the high-magnification graphite negative electrode material of the present embodiment adopts the following steps to prepare:

[0049] 1) Add 10g of furfural resin to 500mL of ethanol, disperse evenly, add 1g of passivated lithium powder, and disperse evenly again to obtain the coating solution; then add 100g of natural graphite to the coating solution and mix evenly, and prepare the precursor by spray drying particles;

[0050] 2) Under a nitrogen atmosphere, the precursor particles are reacted with nitrogen by EDM to prepare a lithium nitride doped precursor; the power of the electric spark is 800W, the voltage is 120V, and the output ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com