Multi-parameter online monitoring system and method for hot-pressing solidification process of composite material

A composite material and monitoring system technology, which is applied in the field of multi-parameter online monitoring system in the hot-press curing process of composite materials, can solve the problems of strain-temperature cross-sensitivity, inability to realize online monitoring, and high difficulty coefficient of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

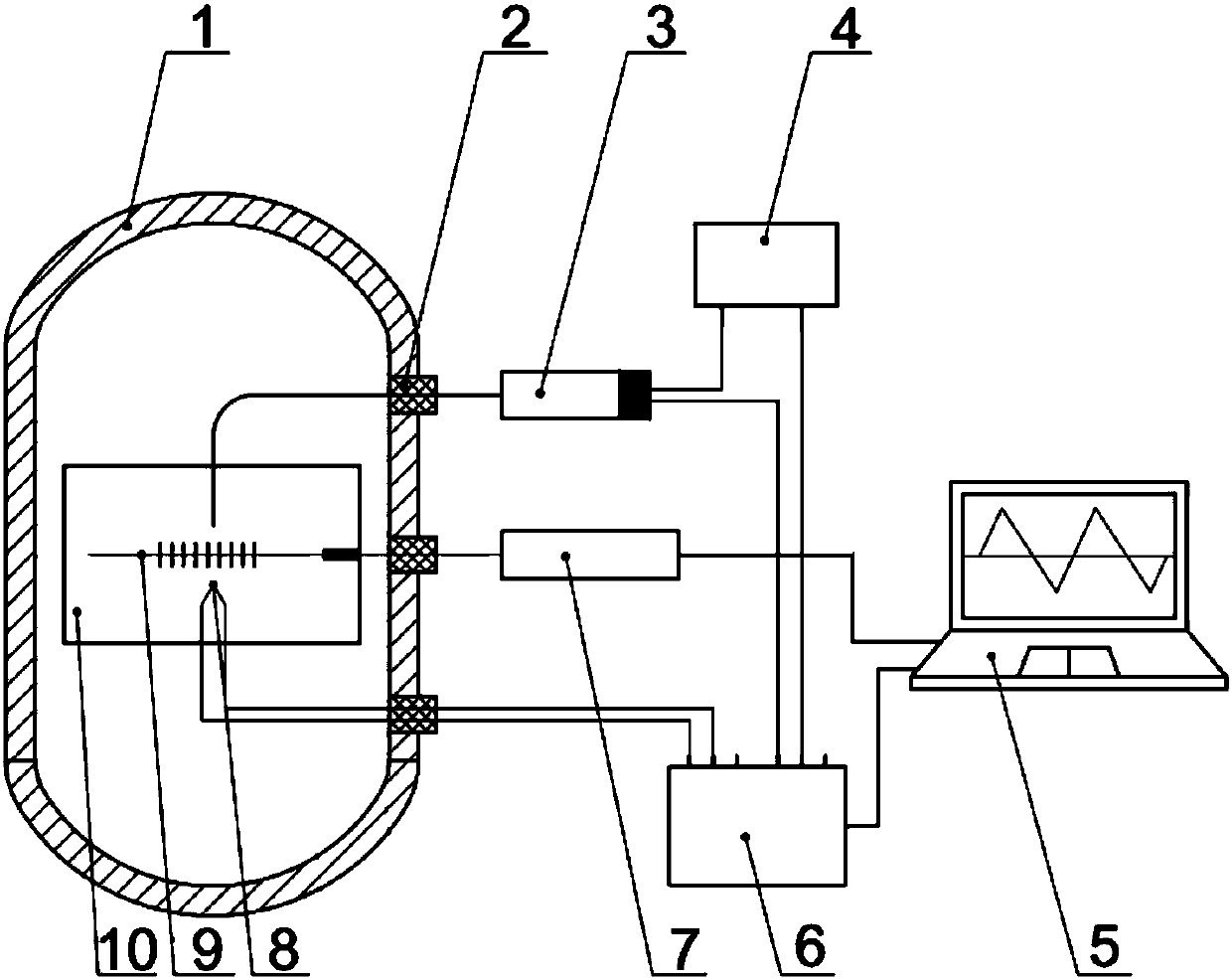

[0055] A multi-parameter online monitoring system for the hot-press curing process of composite materials, see figure 1 , including a temperature sensor 8, a fiber grating sensor 9, a fiber grating demodulator 7, a pressure sensor 3, a data recorder 6 and a host computer 5.

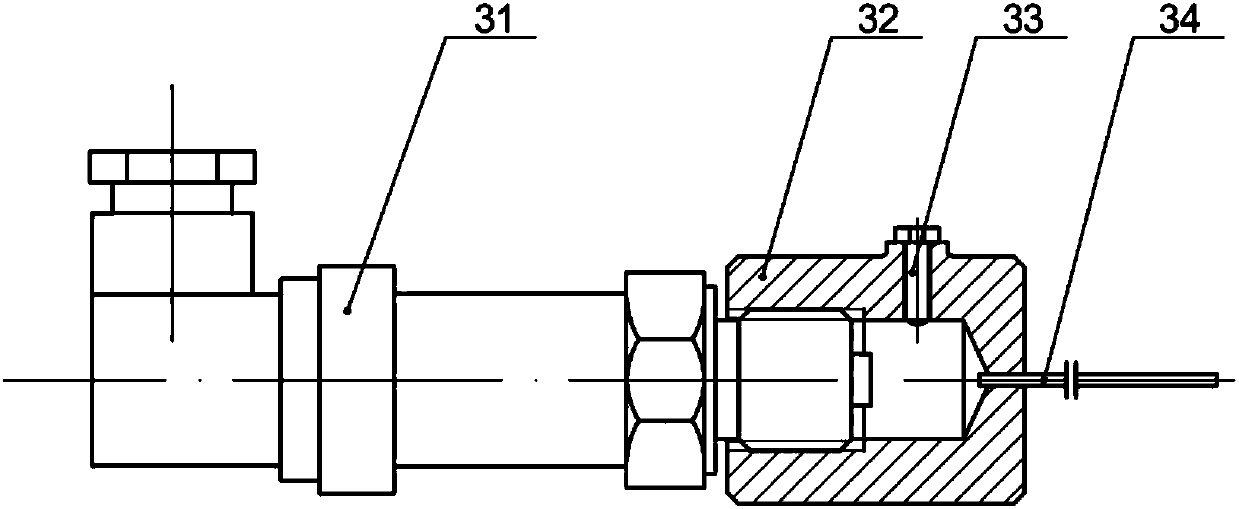

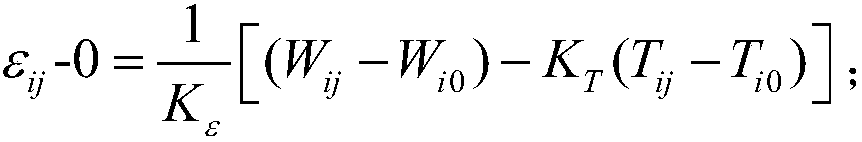

[0056]The hot-press curing process is carried out in the autoclave 1, and multiple measured points can be set for parameter monitoring at multiple positions of the composite material during the hot-press curing process. The measuring end of the temperature sensor 8, the grid area of the fiber grating sensor 9 and the measuring end of the pressure sensor 3 all pass through the reserved hole 2 provided on the autoclave 1 and enter the autoclave 1 and bury it to be monitored. At the measured point of the composite material 10, the reserved hole 2 is sealed with a high temperature resistant sealant. The signal transmission end of the temperature sensor 8 is connected with the data recorder 6 and the data r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com