Production technology of cotton-soybean fiber-polypropylene fiber quick-to-dry fabric

A knitted fabric and production process technology, applied in the field of textile fabrics, can solve problems such as poor wearing comfort and poor skin affinity, and achieve the effects of enhanced moisture drainage, improved moisture regain, and optimized moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

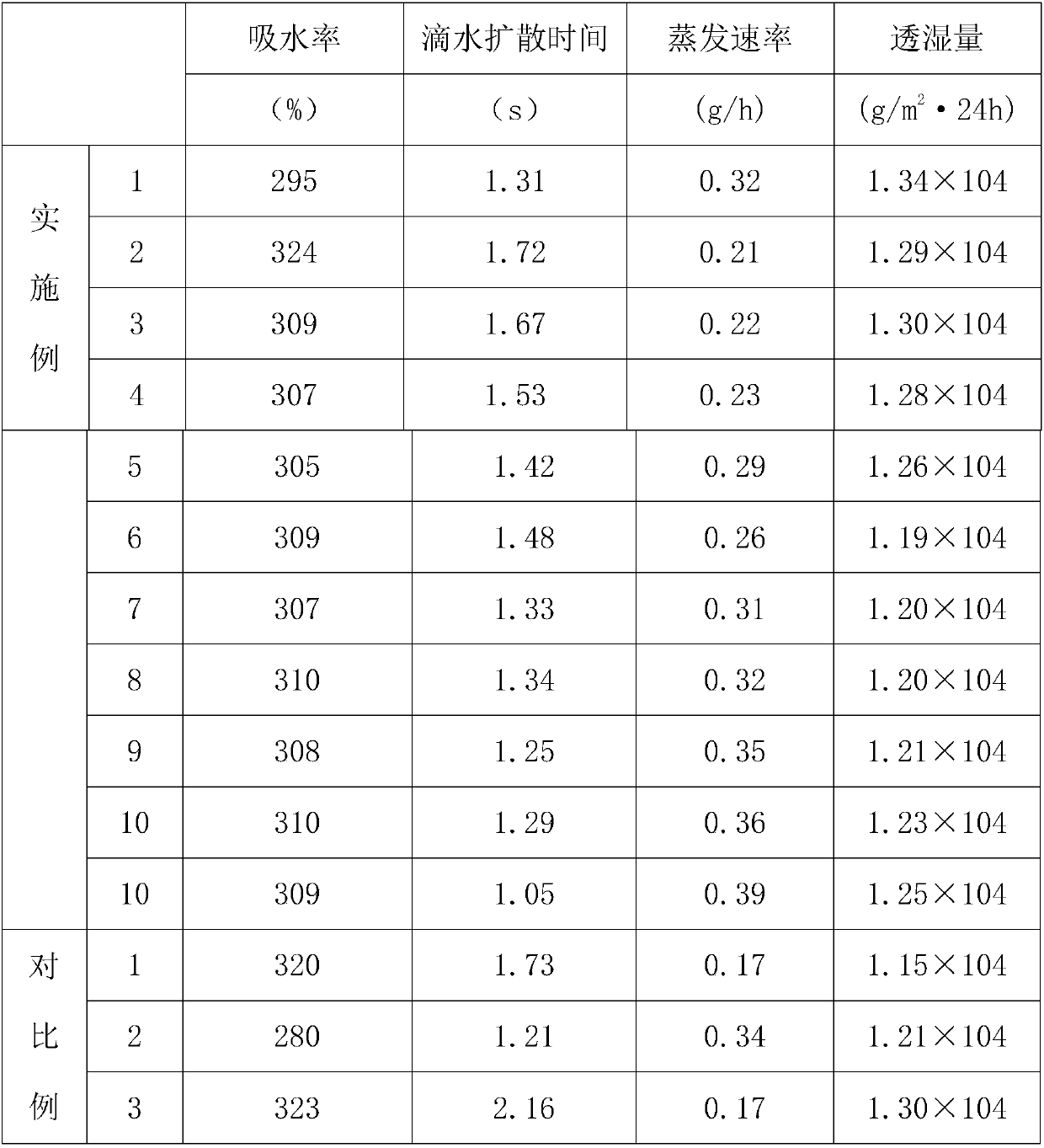

Examples

Embodiment 1

[0020] The production process of cotton soybean fiber polypropylene quick-drying knitted fabric includes the steps of configuring raw fiber, spinning, weaving, dyeing, shaping and soft finishing. The knitted fabric is made of double-sided weft knitting of gray yarn. The percentage by weight is: 20% cotton fiber, 30% soybean fiber and 50% fine-denier polypropylene fiber; the gray yarn spinning process includes a microwave treatment process for the cotton fiber and soybean fiber in the raw material fibers.

[0021] The microwave treatment process parameters of cotton fiber are: microwave frequency 2450MHz, microwave output power 340W, irradiation time 1min; the microwave treatment process parameters of soybean fiber are: microwave frequency 2450MHz, microwave output power 400W, irradiation time 0.6min .

[0022] Example 1 did not undergo dyeing pretreatment before dyeing. The shaping temperature is 150°C, the shaping pressure is 10Kpa, and the vehicle speed is 30m / min. The mai...

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is: the fiber main component and weight percent of gray yarn are: 40% cotton fiber, 30% soybean fiber and 30% fine-denier polypropylene fiber; the microwave treatment process parameter of cotton fiber The microwave frequency is 2450MHz, the microwave output power is 345W, and the irradiation time is 1.5min; the microwave processing parameters of soybean fiber are: the microwave frequency is 2450MHz, the microwave output power is 410W, and the irradiation time is 1min.

Embodiment 3

[0026] The difference between embodiment 3 and embodiment 1 is: the fiber main component and weight percent of gray yarn are: 30% cotton fiber, 35% soybean fiber and 35% fine-denier polypropylene fiber; the microwave treatment process parameter of cotton fiber The microwave frequency is 2450MHz, the microwave output power is 380W, and the irradiation time is 1.2min; the microwave treatment process parameters of soybean fiber are: the microwave frequency is 2450MHz, the microwave output power is 430W, and the irradiation time is 0.8min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com