Ether alcohol composite foaming agent and preparation method thereof

A composite foaming agent, ether alcohol technology, applied in the field of ether alcohol composite foaming agent and its preparation, can solve the problems of foaming performance, thermal stability gap, foaming agent can not meet the development needs of foam concrete, etc., to achieve Excellent foaming performance and stability, expanding the use temperature range, and improving the effect of foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

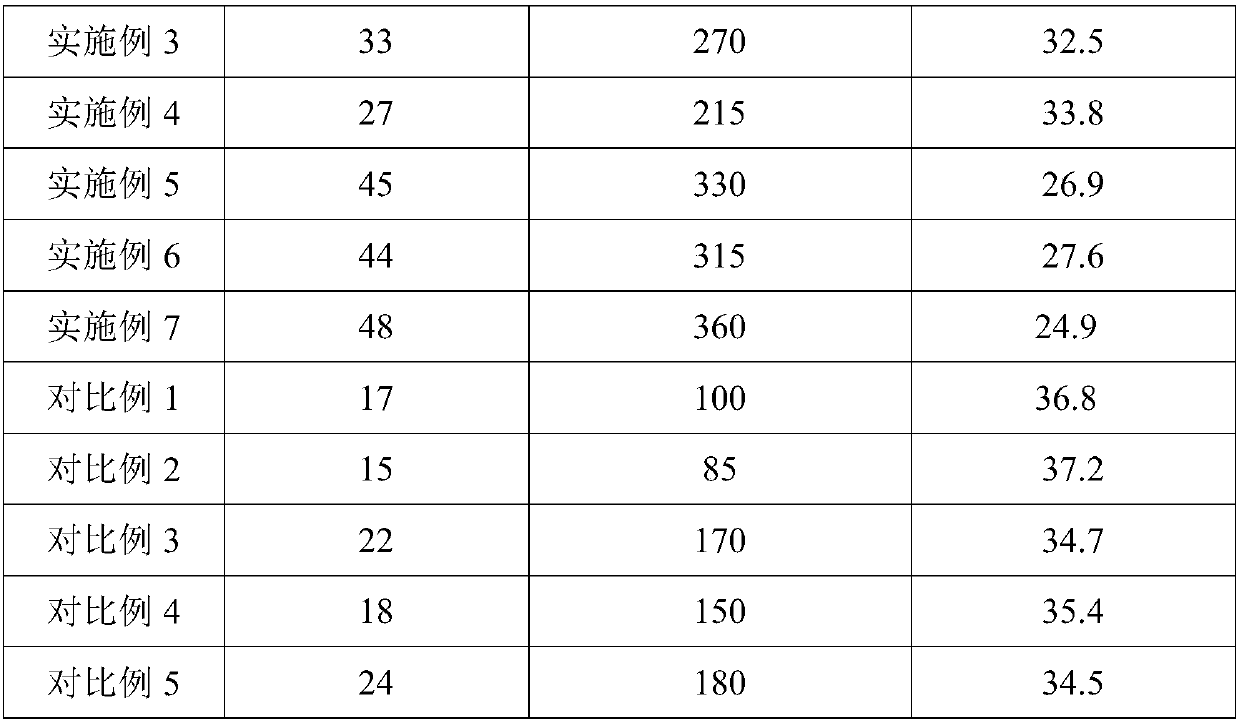

Examples

preparation example Construction

[0064] As a preferred technical solution of the present invention, the preparation method adopted by the isomeric alcohol polyoxyethylene ether includes at least the following steps:

[0065] a) First, mix 20-30% by weight of isomeric fatty alcohol and 5-20% by weight of sodium hydroxide and then stir;

[0066] b) In step a), 50-75% by weight of ethylene oxide is added, and after stirring, the ethoxylation reaction is carried out at 30-50°C for 3-5h.

[0067] The sum of the weight percentages of the isomeric fatty alcohol, sodium hydroxide and ethylene oxide is 100%.

[0068] In a most preferred embodiment, the preparation method adopted by the isomeric alcohol polyoxyethylene ether includes at least the following steps:

[0069] a) First mix 25wt% of isomeric fatty alcohol and 15wt% of sodium hydroxide and then stir;

[0070] b) In step a), 60% by weight of ethylene oxide is introduced, and after stirring, the ethoxylation reaction is carried out at 45° C. for 3 to 5 hours.

[0071] The ...

Embodiment 1

[0114] Example 1 provides an ether alcohol composite foaming agent, and the weight percentage calculation includes at least the following components:

[0115] Ether alcohol surfactant: 5%,

[0116] Amino acid surfactant: 1%,

[0117] Enhancer: 0.1%,

[0118] Stabilizer: 0.01%,

[0119] Water: 93.89%;

[0120] The ether alcohol surfactants are laureth-7 and C 13 The weight ratio of isomeric alcohol ether 10EO is 2:1; the amino acid surfactant is a mixture of sodium lauroyl glutamate and sodium cocoyl glycinate, and the weight ratio is 1:3; the enhancer It is sodium dodecylbenzene sulfonate; the stabilizer is polyacrylamide.

[0121] The preparation method of ether alcohol composite foaming agent includes the following steps:

[0122] At room temperature, add 20wt% of water in the stirring tank, then add 1wt% of amino acid surfactant, stir well, and then add 5wt% ether alcohol surfactant, 0.1wt% enhancer, 0.01wt% stabilizer, fully After stirring, make up the remaining part of the water.

[...

Embodiment 2

[0125] Example 2 provides an ether alcohol composite foaming agent, and the weight percentage calculation includes at least the following components:

[0126] Ether alcohol surfactant: 20%,

[0127] Amino acid surfactant: 8%,

[0128] Enhancer: 1%,

[0129] Stabilizer: 1%,

[0130] Water: 70%;

[0131] The ether alcohol surfactants are laureth-7 and C 13 The weight ratio of isomeric alcohol ether 10EO is 2:1; the amino acid surfactant is a mixture of sodium lauroyl glutamate and sodium cocoyl glycinate, and the weight ratio is 1:3; the enhancer It is sodium dodecylbenzene sulfonate; the stabilizer is polyacrylamide.

[0132] The preparation method of ether alcohol composite foaming agent includes the following steps:

[0133] Add 20wt% water in the mixing tank at room temperature, then add 8wt% amino acid surfactant, stir well, then add 20wt% ether alcohol surfactant, 1wt% enhancer, 1wt% stabilizer, and stir well. After that, make up the remaining part of the water.

[0134] Mix the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| atomic number | aaaaa | aaaaa |

| atomic number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com