Hexavalent chromium reducing agent and preparation method thereof

A reducing agent, hexavalent chromium technology, applied in the field of building materials, can solve problems such as poor high temperature resistance, achieve the effects of preventing oxygen oxidation, solving high temperature resistance and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

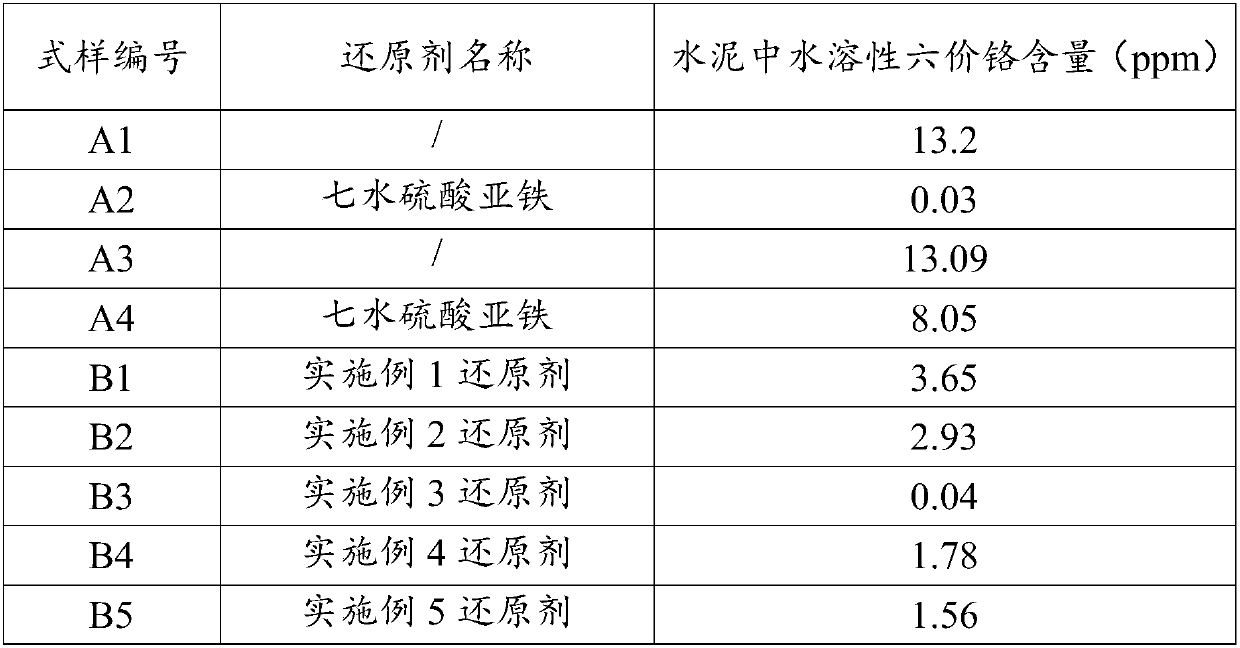

Examples

preparation example Construction

[0026] The present invention also provides a kind of preparation method of hexavalent chromium reducing agent, comprises the following steps:

[0027] In step a, 10-30 parts of dispersant are dissolved in 47-85 parts of water at 30°C-90°C, stirred and left for a period of time, 40-60 parts of iron-containing compound are dissolved in the solution, and stirred again.

[0028] Preferably, the temperature of the water is 50°C-80°C. In this step, the dispersant can be left for 1-2 hours after dissolving to remove air bubbles in the solution.

[0029] In step b, after dissolving 3 to 5 parts of reducing agent in 3 to 5 parts of water to prepare a reducing agent solution, slowly add the reducing agent solution dropwise to the solution prepared in step a, and continue stirring to obtain a dispersed nanometer zero-valent iron agent solution.

[0030] During specific implementation, since the reducing agent solution is added to the solution prepared in step a and stirred, a large num...

Embodiment 1

[0036] Dissolve 15 g of sodium carboxymethyl cellulose in 85 g of water at 40° C., and place it for 1 hour to completely remove the air bubbles to obtain an aqueous solution of sodium carboxymethyl cellulose. 5 g of sodium borohydride was dissolved in 5 g of water to obtain an aqueous solution of sodium borohydride.

[0037] Dissolve 50 g of ferrous sulfate into the above-mentioned sodium carboxymethyl cellulose aqueous solution, then gradually add the above-mentioned sodium borohydride aqueous solution dropwise, and stir for 1 hour to obtain an aqueous sodium carboxymethyl cellulose solution containing 10 g of nanometer zero-valent iron.

[0038] Mix 10 g of sodium carboxymethyl cellulose solution of nano zero-valent iron with 90 g of ferrous sulfate heptahydrate and stir for 3 hours, and dry in an oven at 50°C for 8 hours under nitrogen protection to prepare nano-zero-valent iron particles and carboxymethyl Sodium cellulose coated hexavalent chromium reducing agent.

Embodiment 2

[0040] Dissolve 10 g of sodium alginate in 47 g of water at 30° C., and place it for 2 hours to completely remove air bubbles to obtain an aqueous solution of sodium alginate. 3 g of sodium borohydride was dissolved in 3 g of water to obtain an aqueous solution of sodium borohydride.

[0041] Dissolve 40g of ferrous sulfate into the above-mentioned sodium alginate aqueous solution, then gradually add the above-mentioned sodium borohydride aqueous solution dropwise, and after stirring for 1 hour, an aqueous sodium alginate solution containing 8g of nanometer zero-valent iron is obtained.

[0042] Mix 15 g of sodium alginate solution of nano-zero-valent iron with 60 g of ferrous sulfate heptahydrate and stir for 2.5 hours, and dry in an oven at 30°C for 48 hours under nitrogen protection to prepare nano-zero-valent iron particles and sodium alginate-wrapped Hexavalent chromium reducing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com