Method and device for improving energy efficiency of molten iron storage and transportation

A molten iron and energy efficiency technology, applied in the field of metallurgy, can solve the problems of large surface heat loss of molten iron, lack of heat preservation measures in molten iron, energy loss of molten iron, etc., so as to reduce the loss of molten iron, improve metal yield, and reduce the effect of dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

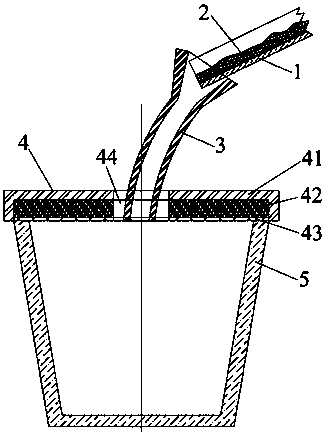

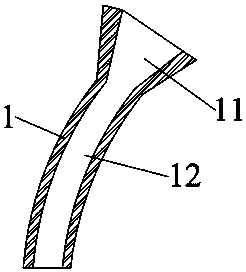

[0026] Such as figure 1 and figure 2 , this embodiment relates to a bushing for tapping, including a bushing body 3, the bushing body 3 defines an inner cavity, and the inner cavity forms a tapping channel, that is, during the tapping process, the molten iron 2 flows from the The sleeve body 3 flows into the molten iron storage and transportation equipment 5, which can isolate the molten iron 2 from the air, so that the tapping process can be carried out under the condition of sealing, heat preservation and protection as much as possible. The casing body 3 includes an upper funnel-shaped inlet section 11 and a lower column-shaped drainage section 12, the inlet section 11 is coaxially connected with the drainage section 12; the diameter of the top of the inlet section 11 is larger than the width of the molten iron chute 1 . The funnel-shaped inlet section 11 is provided to receive the molten iron 2 , and the top of the drainage section 12 communicates with the bottom of the ...

Embodiment 2

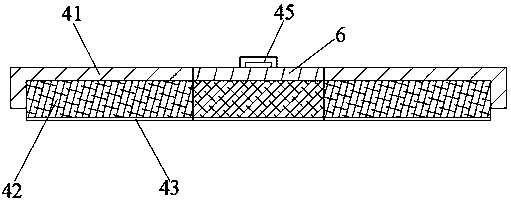

[0030] Such as Figure 3-Figure 4 , this embodiment relates to a thermal insulation cover 4, which is covered on the storage and transportation equipment for storing and transporting molten iron 2 or molten steel, and includes a casing 41 and a first thermal insulation body arranged on the inner surface of the casing 41. The casing 41 is provided with a liquid inlet, and the liquid inlet extends downwards and passes through the first heat insulating body to form a liquid inlet channel 44 . Wherein, the length, width or diameter of the liquid inlet should be greater than the diameter of the molten iron flow column or the molten steel flow column, so that the molten iron 2 or molten steel can enter the storage and transportation equipment along the liquid inlet channel 44 . By arranging the insulation cover 4, a near-closed inner chamber containing molten iron 2 / molten steel is formed with the body of the storage and transportation equipment, and the storage and transportation e...

Embodiment 3

[0036] Such as figure 1 , the present embodiment relates to a device for improving the energy efficiency of molten iron storage and transportation, including a thermal insulation channel and a thermal insulation cover 4 covered on the molten iron storage and transportation equipment 5, and the thermal insulation cover 4 and the molten iron storage and transportation equipment 5 body form a closed interior cavity, the heat preservation cover 4 is provided with an iron inlet 44, and the heat preservation channel extends from the outlet end of the molten iron chute 1 to the iron inlet 44. The above-mentioned heat preservation channel is preferably the tapping bushing described in Embodiment 1, and the above heat preservation cover 4 is preferably the heat preservation cover 4 described in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com