High-quality centrifugal casting method for steel pipe blank

A technology of centrifugal casting and steel tube billet, applied in the field of high-quality centrifugal casting steel tube billet, can solve the problems of uneven material, uneven distribution, difficult control, etc., to reduce inclusion content, high metal yield, and prevent oxygen oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Centrifugal casting of high-quality 4140 steel pipe billet for petroleum, its specification is φ550 / 350×2000mm, its centrifugal casting method:

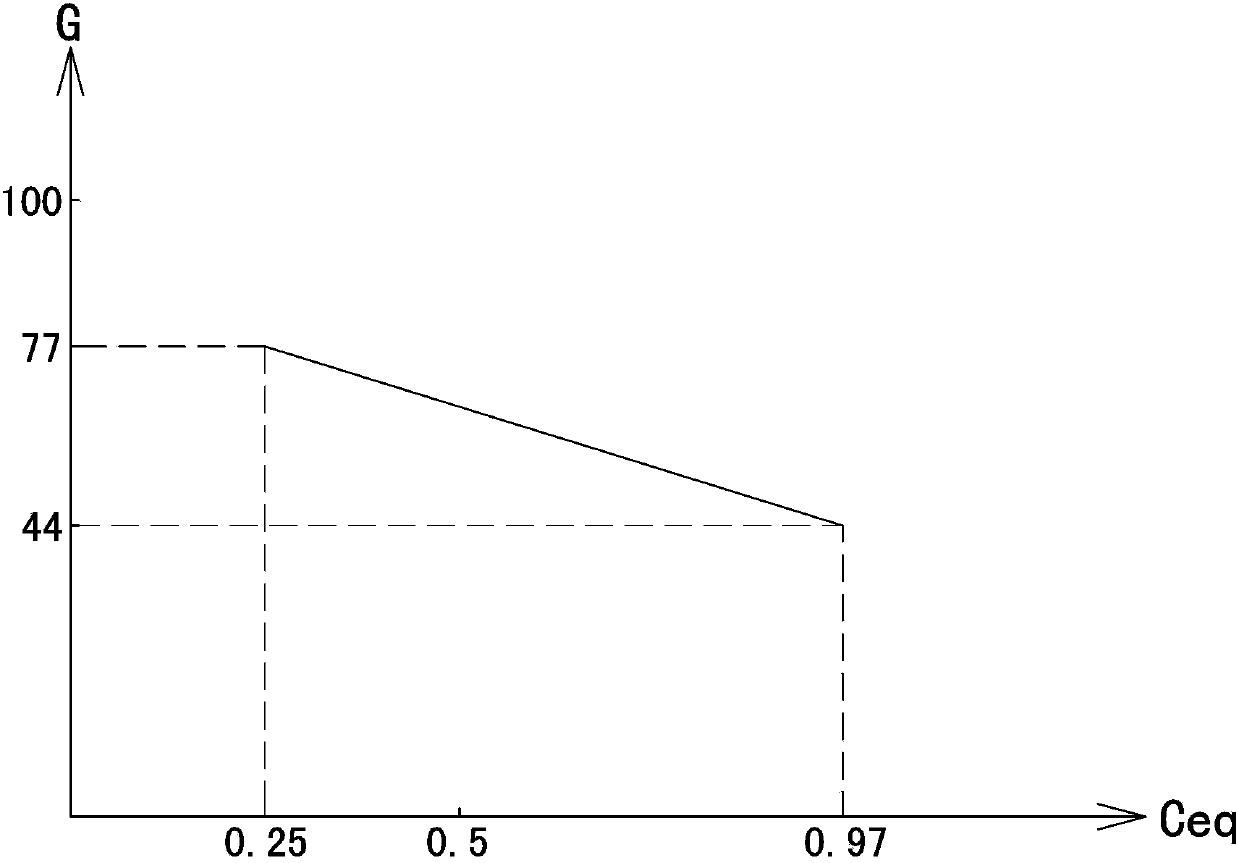

[0017] (1) According to the formula N=20×(G / r) 1 / 2 , first calculate the carbon equivalent Ceq=0.773 of the 4140 petroleum steel pipe billet, according to figure 2 The linear relationship shown: from the figure, Ceq=0.773 corresponds to G to take 57, the radius of the inner surface of the steel pipe billet is taken into consideration of 10mm machining allowance to take 0.165m, and the calculated centrifugal speed is 370r / min;

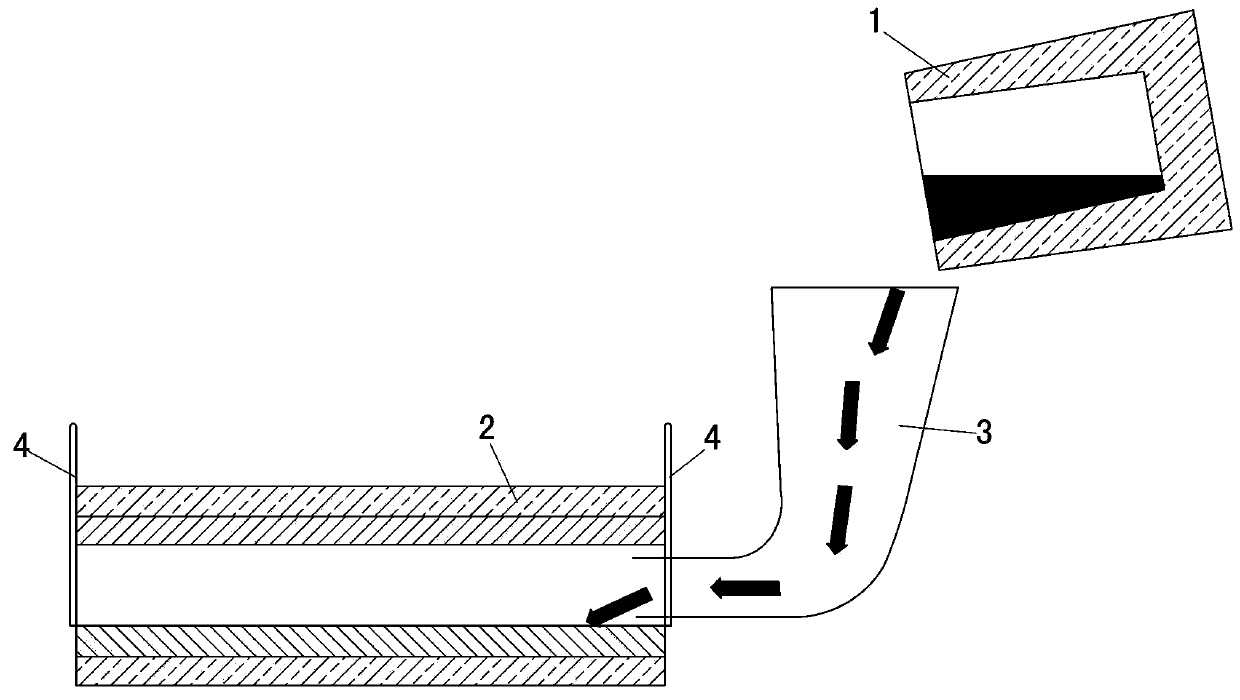

[0018] (2) Adjust the speed of the centrifuge to 370r / min, pour molten steel from the ladle into the cavity, combine figure 1 As shown, a funnel-shaped tundish 3 is connected between the ladle 1 and the cavity 2, and argon gas is introduced from the ladle 1, and the flow rate of the argon gas is 150 L / min, so that the argon gas enters the tundish 3 and the cavity 2 , the two open ends of the cavity 2...

Embodiment 2

[0021] Centrifugal casting of high-quality 45# steel billet, its specification is φ460 / 350×2000mm, its centrifugal casting method

[0022] (1) According to the formula N=20×(G / r) 1 / 2 , Ceq=0.61, according to figure 2 In the linear relationship diagram shown, G is 60, and the inner surface radius of the steel tube billet is 0.165m considering the 10mm machining allowance, and the calculated centrifugal speed is 380r / min;

[0023] (2) Adjust the speed of the centrifuge to 380r / min, pour molten steel from the ladle into the cavity, combine figure 1 As shown, a funnel-shaped tundish 3 is connected between the ladle 1 and the cavity 2, and argon gas is introduced from the ladle 1, and the flow rate of the argon gas is 120 L / min, so that the argon gas enters the tundish 3 and the cavity 2 , surrounded by the outer layer of molten steel; the two open ends of the cavity 2 are sealed with two baffles 4, so that the tundish 3 is sealed and extends into the inner cavity of the cavity ...

Embodiment 3

[0026] Method for Centrifugal Casting High Quality 65Mn Steel Billet (Specification φ420 / 240×2000)

[0027] (1) Quickly calculate the centrifugal speed.

[0028] According to N=20×(G / r) 1 / 2 . Ceq=0.817, according to figure 2 In the shown relationship, G is 55, the radius of the inner surface of the steel tube billet is 0.110m (considering the machining allowance of 10mm), and the calculated centrifugal speed is 450r / min.

[0029] (2) Using gas protection pouring.

[0030] Adjust the speed of the centrifuge to 450r / min, control the pouring temperature within the range of 1528-1538°C, and the liquidus temperature of the steel is 1508°C. Gas protection casting is adopted, the weight of the centrifugal steel billet is 1.9 tons, and the time control is completed within 4 minutes. Gas protection methods such as figure 1 As shown, one is to use a funnel-shaped tundish. The tundish can protect the stage from the tapping hole to the launder from oxygen pollution. Adding a funnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com