Molybdenum-cobalt-boron ternary boride base metal ceramic material and preparation method thereof

A technology of ternary borides and ceramic materials, which is applied in the field of cutting tools, can solve the problems of low self-diffusion coefficient, difficult sintering and compactness, and incomparable problems, and achieve the effects of stable chemical properties, lower sintering temperature, and improved product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a MoCoB type ternary boride-based cermet material of the present invention comprises the following process steps: using elemental molybdenum powder, elemental cobalt powder, and elemental boron powder as raw materials, according to a certain powder ratio, through a powder mixing process, and drying process, pressing process and sintering to obtain a ternary boride cermet material with MoCoB type double boride as the main phase.

[0023] The properties of the powder are: the purity of molybdenum powder is >99%, particle diameter (0.01~10μm); the purity of cobalt powder is >99%, particle diameter (0.01~10μm); the purity of boron powder is >99%, particle diameter (0.01~10μm).

[0024] For the powder ratio, if the atomic number of the powder ratio is MoxCoyBz, and x, y and z are the atomic numbers of the corresponding powder, it is required that 1.40≥z / x≥1.12, and 2.2≥y / x≥1.

[0025] The powder mixing process adopts a dry mixing method or a wet mixi...

Embodiment 1

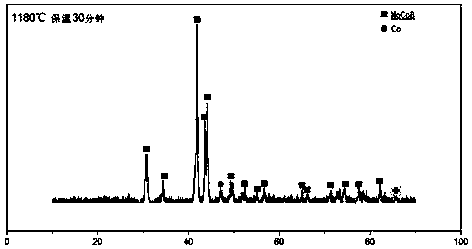

[0035] Weigh Mo23.99g, Co18.87g, and B3.105g respectively; mix the materials, sieve to obtain a uniformly mixed powder, and press molding with a pressure of 250Mpa and a holding time of 120s, sintering under an argon atmosphere, and the sintering temperature At 1180°C, the holding time is 30min, the heating rate is 5°C / min, and the furnace cools down. The hard phase of the prepared sample is MoCoB dual phase, the binder phase is Co, and the sample density is 8.13g / cm 3 , Rockwell hardness can reach 83.5HRA.

Embodiment 2

[0037] Weigh Mo23.99g, Co18.87g, and B3.24g respectively; mix the materials, sieve to obtain a uniformly mixed powder, and press molding with a pressure of 250Mpa and a holding time of 120s, through a tube furnace under an argon atmosphere. Sintering, the sintering temperature is 1200°C, the holding time is 30min, the heating rate is 5°C / min, and the furnace cools down. The hard phase of the prepared sample is MoCoB dual phase, the binder phase is CoB, and the density is 8.19g / cm 3 , Rockwell hardness can reach 83.7HRA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com