Novel environment-friendly anti-rust paint and preparation method thereof

An anti-rust paint, environmental protection technology, applied in the field of anti-rust paint, can solve the problems of polluting the environment, poor use effect, irritating odor, etc., to achieve the effect of environmental protection of raw materials, good performance and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

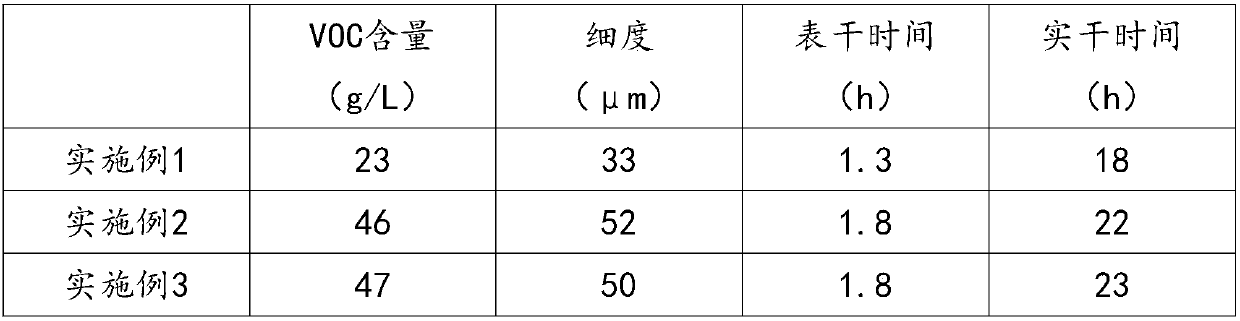

Examples

Embodiment 1

[0019] Put 40 parts of water-based epoxy resin, 10 parts of talcum powder, 5 parts of titanium dioxide, 5 parts of aluminum tripolyphosphate, 3 parts of ceramic hollow microspheres, and 20 parts of deionized water into the reactor for heating, and set the temperature to 70 ° C, and Stir uniformly with the aid of ultrasonic vibration, and the stirring time is 40 minutes to obtain the basic material;

[0020] Mix 10 parts of tung oil and 10 parts of vegetable starch, and put them into an extruder to puff for 30 minutes. After the puffing is completed, take out the material and put it into a closed container for heating. The closed container is filled with ethanol vapor and carbon dioxide gas, ethanol vapor and carbon dioxide. The volume ratio of the gas is 3:1, and the heating temperature is 65°C to obtain the modification additive;

[0021] Mix the obtained basic material, modification additive and 3 parts of titanium dioxide and put them into a high-pressure heating furnace fo...

Embodiment 2

[0024] Put 50 parts of water-based epoxy resin, 15 parts of talcum powder, 10 parts of titanium dioxide, 10 parts of aluminum tripolyphosphate, 5 parts of ceramic hollow microspheres, and 25 parts of deionized water into the reactor for heating, and set the temperature to 80 ° C, and Stir uniformly with the aid of ultrasonic vibration, and the stirring time is 60 minutes to obtain the basic material;

[0025] Mix the obtained basic material with 5 parts of titanium dioxide and put it into a high-pressure heating furnace for heating. The heating temperature is set at 60°C and the heating time is 20 minutes. During the heating process, hydrogen gas is introduced, and the synthetic material is obtained after the heating is completed;

[0026] The synthetic material is mixed with 1 part of silicone defoamer, 1 part of polyacrylic acid dispersant, and 4 parts of film-forming aids, and then injected into the grinder. The speed of the grinder is 1500r / min, and the grinding temperature...

Embodiment 3

[0028] Take conventional antirust paint sold on the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com