A kind of natto compound preparation and preparation method thereof

A compound preparation, natto technology, applied in the biological field, can solve the problems of not meeting the public taste, poor taste, smelly and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

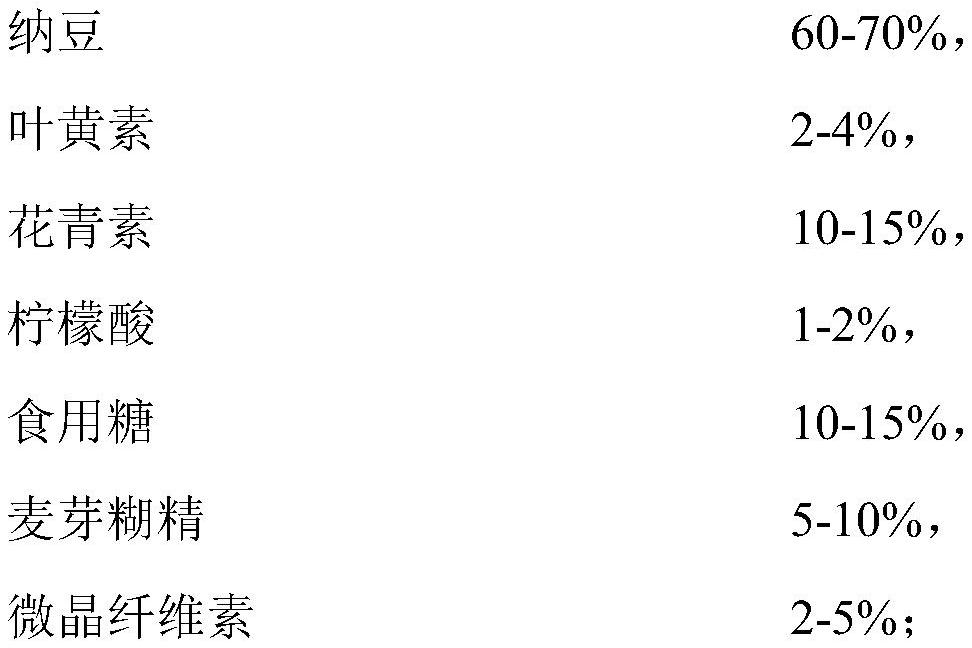

Method used

Image

Examples

Embodiment 1

[0040] Cultivation of Bacillus natto: Use an inoculation loop to inoculate 150 mL of sterilized (115°C, 30 minutes) seed fermentation medium with activated Bacillus natto strains (purchased from the Culture Collection Center of the Institute of Microbiology, Chinese Academy of Sciences) with an inoculation loop , The composition of the seed fermentation medium is 0.5% beef extract, 0.5% yeast extract, 0.5% peptone, 0.5% glucose, 0.5% NaCl, and the rest is deionized water, pH7.0. The seed fermentation culture after inoculation is based on shaking (160 rpm) cultivation in a shaker at 36° C. for 24 hours, and the next step of expanding inoculation is carried out.

[0041] Secondary fermentation of black soybeans and natto: Wash 1kg of plump and insect-free black soybeans, soak them in 3 times the water overnight, grind soybean milk with a refiner, steam the soybean dregs and save them for later use. Add 2% anhydrous glucose and 0.3% NaCl to the obtained about 4L soybean milk, pla...

Embodiment 2

[0045] Cultivation of Bacillus natto: Use an inoculation loop to inoculate the activated Bacillus natto strains (purchased from the Culture Collection Center of the Institute of Microbiology, Chinese Academy of Sciences) into 200 mL of sterilized (115°C, 30 minutes) seed fermentation medium , The composition of the seed fermentation medium is 0.5% beef extract, 0.5% yeast extract, 0.5% peptone, 0.5% glucose, 0.5% NaCl, and the rest is deionized water, pH7.0. The seed fermentation culture after inoculation is based on shaking (160 rpm) in a shaker at 36°C for 36 hours, and the next step is to expand the inoculation.

[0046] Secondary fermentation of black soybeans and natto: Wash 1.5kg of plump and insect-free black soybeans, soak them in 4 times of water overnight, grind soybean milk with a refiner, steam the soybean dregs and save them for later use. Add about 8L of soybean milk obtained with 3% anhydrous glucose and 0.6% NaCl, place in a conventional 10L aerobic aerated fer...

Embodiment 3

[0050] Cultivation of Bacillus natto: Use an inoculation loop to inoculate the Bacillus natto strain after the slant activation into 200mL sterilized (115°C, 30 minutes) seed fermentation medium, the composition of the seed fermentation medium is 0.5% Beef extract, 0.5% yeast extract, 0.5% peptone, 0.5% glucose, 0.5% NaCl, and the rest are deionized water, pH 7.0. The seed fermentation culture after inoculation is based on shaking (160 rpm) in a shaker at 36° C. for 32 hours, and the next step of expanding inoculation is carried out.

[0051] Fermentation of black soybeans and natto: Wash 1.5kg of plump and insect-free black soybeans, soak them in 3 times the water overnight, grind soybean milk with a refiner, steam the soybean dregs and save them for later use. Add 2.5% anhydrous glucose and 0.5% NaCl to the obtained about 8L soybean milk, place in a 10L aerobic aeration fermenter, sterilize at 115°C for 20 minutes, cool to room temperature (about 25°C), press 4 % of the ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com