Coupling analysis method of rod cluster subchannel and critical heat flux mechanism model

A technology of critical heat flux and mechanism model, which is applied in the fields of electrical digital data processing, computer-aided design, and special data processing applications, etc., can solve problems such as inconvenient updates and decreased prediction accuracy, and achieve the effect of facilitating critical heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

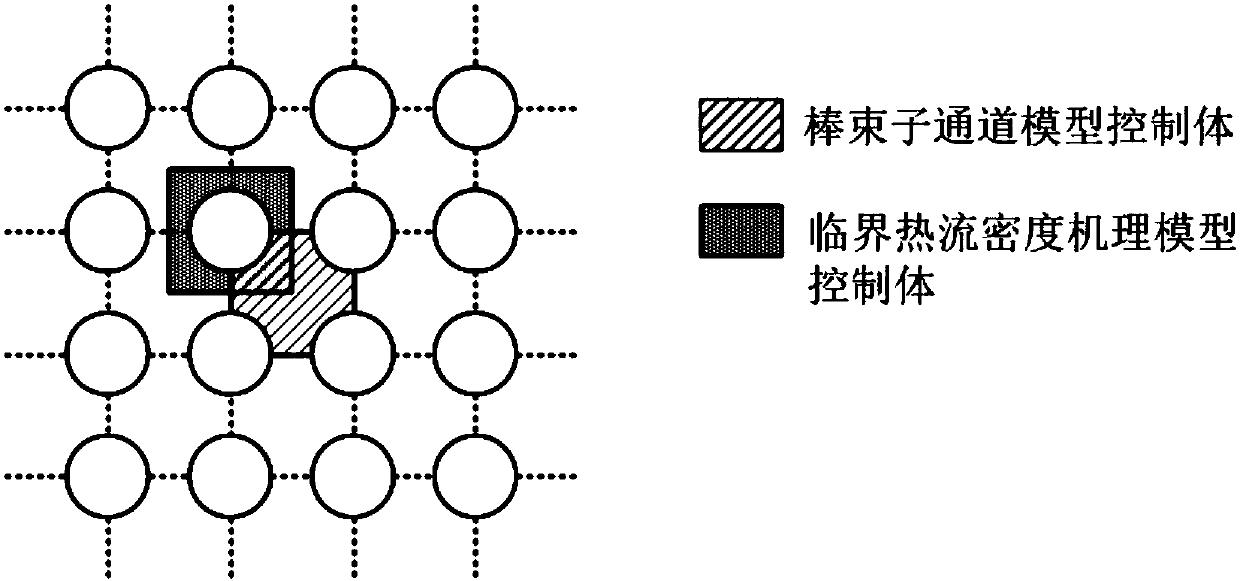

[0020] like figure 1 As shown, a coupling analysis method of the rod bundle sub-channel and the critical heat flux mechanism model of the present invention, the specific method is as follows:

[0021] Step 1: Given the geometric dimensions of the rod bundle sub-channel, the boundary conditions include inlet temperature, inlet flow rate, outlet pressure and average heat flux q o , set the axial and radial power factors, and use the sub-channel analysis method to calculate the two-phase transient flow field in the flow channel, so as to obtain the local thermal-hydraulic parameters in each flow channel, including pressure, flow and enthalpy, so that the critical The heat flux mechanism model provides coupling parameters.

[0022] Step 2: When the thermal-hydraulic parameters in the rod bundle sub-channels calculated in step 1 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com