Novel rotary device used on hydraulic rock drill

A technology of hydraulic rock drill and rotary device, which is applied to the rotary function of hydraulic rock drill and the field of rotary device used on new hydraulic rock drill, can solve the problems of strong, high noise, oil mist and the like, so as to alleviate the impact and vibration, Improve transmission efficiency and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

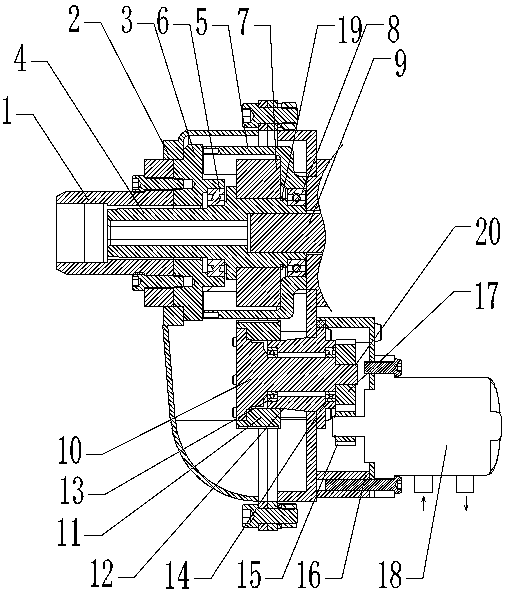

[0026] Examples such as figure 1 As shown, a rotary device used on a new type of hydraulic rock drilling machine includes a hydraulic rock drilling machine cover 2, a hydraulic rock drilling machine cover 2 is provided with a shank sleeve 4 for fixing and installing a drill tail and a piston 9, and the hydraulic rock drilling machine cover 2 A hydraulic motor 18 is fixedly installed on the outside, and the hydraulic motor 18 drives the shank 4 to rotate through a three-stage transmission device.

[0027] A core body 5 is arranged inside the hydraulic rock drilling machine cover 2, and the shank 4 is installed in the core body 5. The front end of the core body 5 and the cover body of the hydraulic rock drilling machine cover 2 are sealed by a pressure plate 3, and the pressure plate 3 is set The outside of the shank 4 and the shank 4 are rotatably connected through the first bearing 6 .

[0028] The rear end of the core body 5 is also rotatably connected to the shank 4 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com