Distributed type airborne direct current power supply system based on snake-like robot

A snake-like robot and power supply system technology, applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve problems such as limited capacity, difficulty in driving super-torque steering gear, and difficult wiring, so as to improve movement ability and mobility, improve Insufficient driving force of the joints, convenient and easy wiring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0032] Such as figure 1 , 2 , 3, and 4 show:

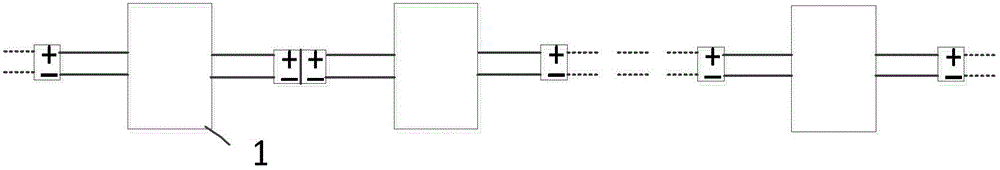

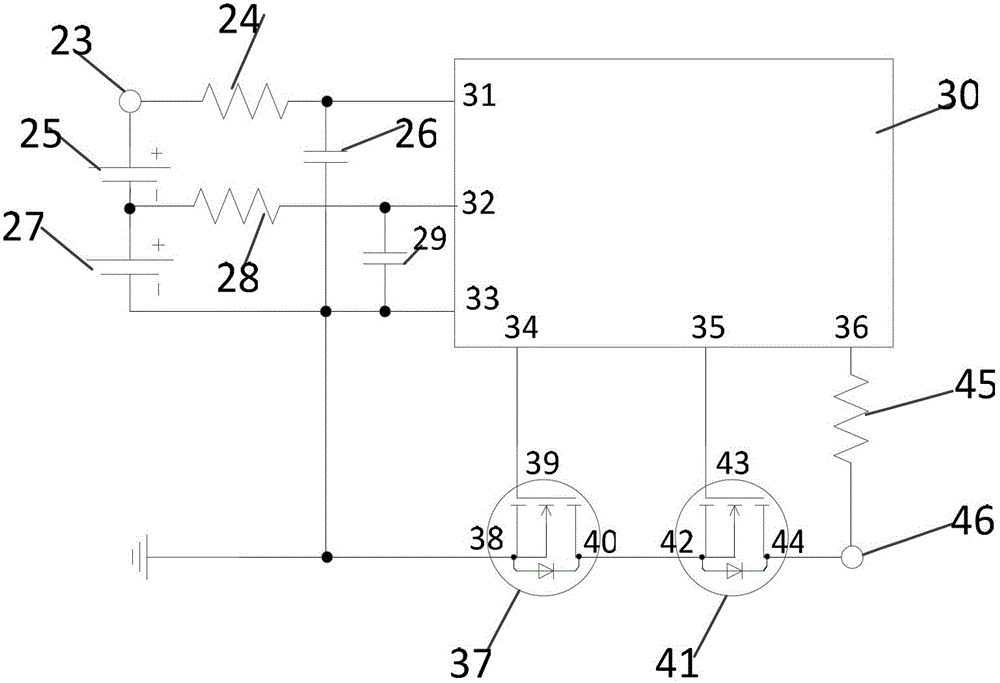

[0033] Based on the distributed airborne DC power supply system of the snake-like robot, the present invention can include multiple power supply nodes 1 according to the number of joints of the snake-like robot. Each power supply node 1 can output two kinds of voltages, which are respectively used by specific components. The output voltage is determined by the first lithium battery cell 25 , the second lithium battery cell 27 and the three-terminal voltage regulator 65 . Moreover, the second male interface 10 or the second female interface 13 drawn from the power supply node can be connected in parallel to each other to form a power supply network, thereby achieving the purpose of evenly distributing current loss and lasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com