Speed changing device, gear-shifting control method, electric car driving system and electric car

A technology of a speed change device and passive element, which is applied in the field of transmission system, can solve the problems of power interruption, the inability to achieve both the power performance and the power consumption economy of electric vehicles, and the inability to give full play to the power performance and economy of the whole vehicle at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

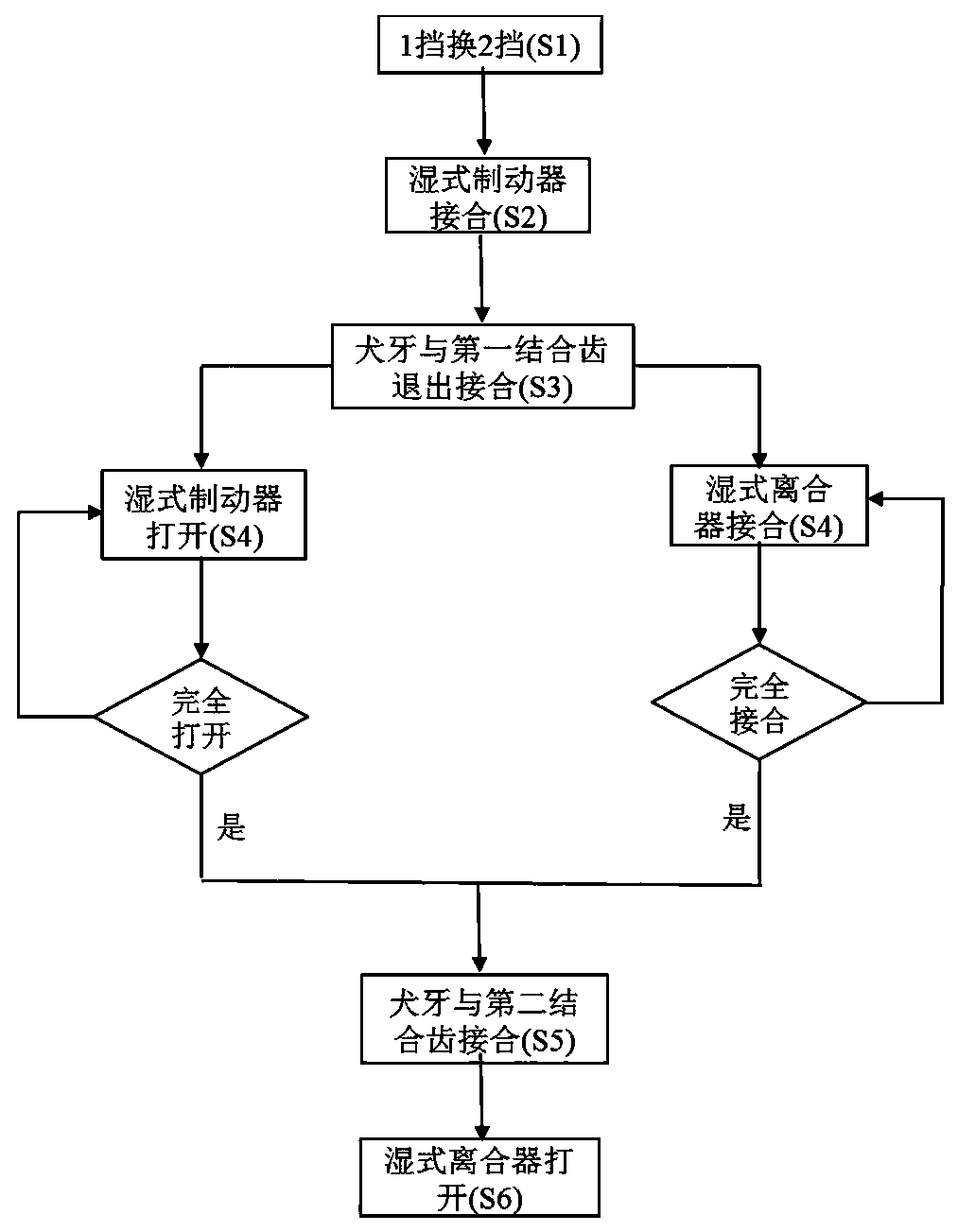

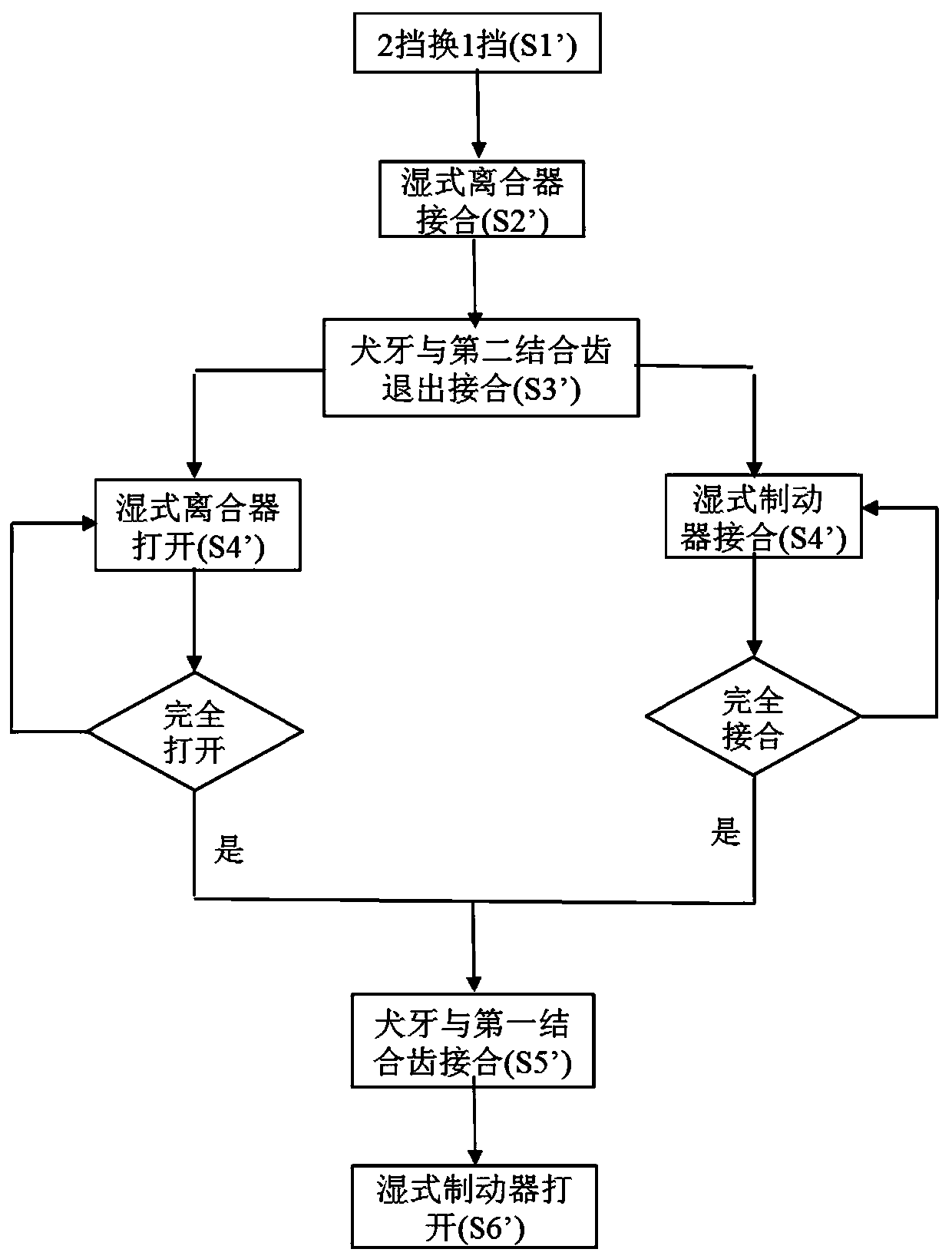

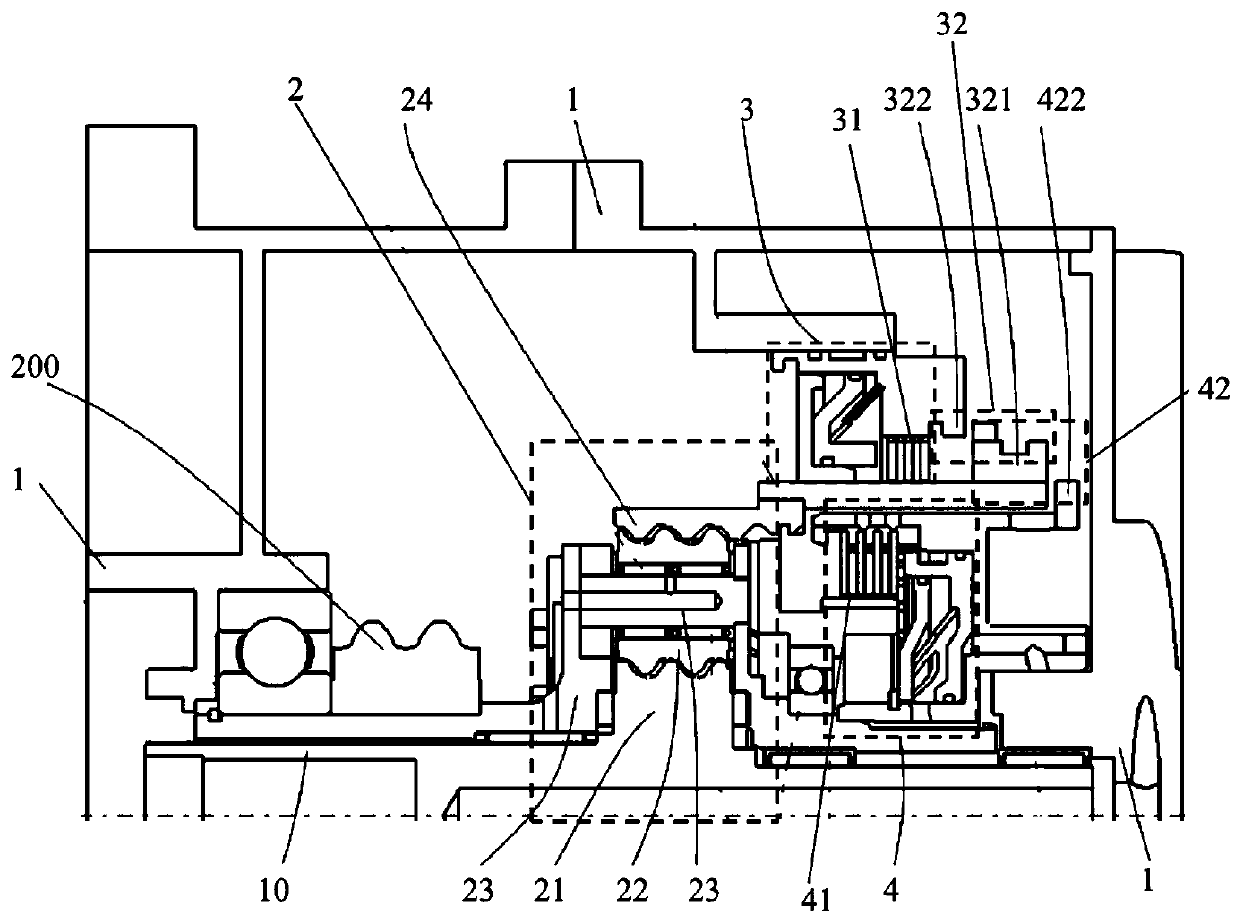

[0033] The following is a description of exemplary embodiments of the application, examples of which are illustrated in the accompanying drawings.

[0034] For purposes of brevity and illustration, the principles of the application are described herein primarily with reference to exemplary embodiments thereof. However, those skilled in the art will readily recognize that the same principles are equally applicable to and can be implemented in all types of transmissions and shift control methods without departing from this patent application. true spirit and scope. Moreover, in the following description, reference is made to the accompanying drawings, which illustrate certain exemplary embodiments. Electrical, mechanical, logical and structural changes may be made to these embodiments without departing from the spirit and scope of the application. Furthermore, although a feature of the present application is disclosed in connection with only one of several implementations / embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com