Composite self-cleaning nanometer coating, inorganic transparent coating layer and self-cleaning product

A nano-coating, transparent coating technology, applied in coatings, conductive coatings, antifouling/underwater coatings, etc., can solve problems such as high adhesion and inability to solve quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

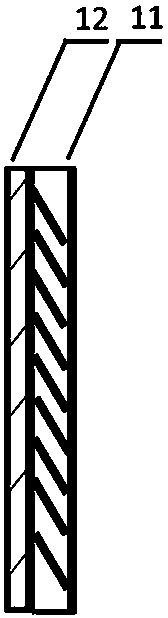

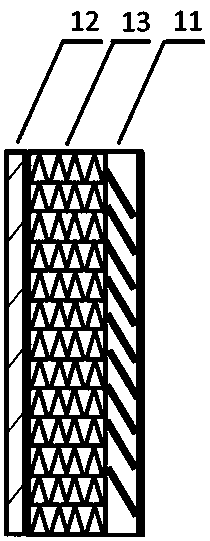

Image

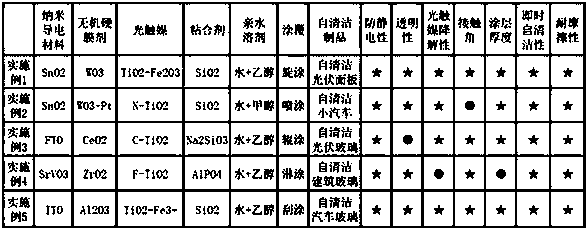

Examples

Embodiment 1

[0034] ⑴ Preparation of nano-conductive SnO 2 . 25 parts by weight of tin tetrachloride hydrate (SnCl 4 ·5H 2 O) be dissolved in 100 weight parts deionized water, drop the 25wt% concentrated ammonia water of 30 weight parts, tin ion is completely converted into Sn(OH) 4 Precipitate, wash with water 5 times to remove chloride ions, etc., then disperse into 100 parts by weight of deionized water and adjust the pH to 10.5 with ammonia water, and quickly add 1.2 parts by weight of sodium peroxide Na 2 o 2 , all transferred to the hydrothermal reaction kettle, after hydrothermal reaction for 5 hours, cool down to room temperature, wash 5 times with deionized water with the help of nanofiltration membrane to remove residual impurities such as nano-ions, transfer the off-white substance on the surface of the filter to the container and add Appropriate amount of water, you get SnO 2 An aqueous dispersion of conductive nanoparticles with a solid content of 9.8 g / ml, and SnO 2 The...

Embodiment 2

[0044] ⑴ Preparation of nano-conductive SnO 2 , SnO with a solid content of 9.8g / ml 2 Aqueous dispersion, SnO 2 The particle size is about 2nm, the same as in Example 1.

[0045] ⑵Purchase hard film a, WO with a solid content of 5wt% 3 Methanol dispersion, WO 3 The particle size is less than 100 nanometers.

[0046] Purchase hard coat agent b, an aqueous dispersion of platinum particles with a solid content of 1 wt%, and a Pt particle size of less than 100 nanometers.

[0047] (3) Buy nitrogen-doped titanium dioxide photocatalyst, N-TiO with a solid content of 5wt% 2 Aqueous dispersion, N-TiO 2 The particle size is less than 100 nanometers.

[0048] ⑷ purchase adhesive A, solid content is 20wt% SiO 2 Methanol dispersion, SiO 2 The particle size is less than 10 nanometers.

[0049] Binder B was purchased, amorphous SiO with a solid content of 1.5 wt% 2 Aqueous dispersion, SiO 2 The particle size is less than 2 nanometers.

[0050] ⑸ Preparation of composite self-cl...

Embodiment 3

[0054] ⑴ Self-made nano-conductive FTO. 10 parts by weight of tin tetrachloride (SnCl 4 ·5H 2 O) the hydrate is dissolved in 100 parts by weight of deionized water, and 30 parts by weight of 25wt% concentrated ammonia water is added dropwise, so that tin ions are completely converted into Sn(OH) 4 Precipitate, wash with water 5 times to remove chloride ions, transfer the precipitate to the hydrothermal reaction kettle, add 0.1 parts by weight of hydrofluoric acid (HF) and 20 parts by weight of deionized water, and then heat the hydrothermal reaction kettle to 180 °C And keep at constant temperature for 15 hours and then cool to room temperature. After separating the turbid liquid in the reaction kettle, a colorless precipitate was obtained, indicating that fluoride ions had been doped into SnO 2 Lattice-generated conductive nano-FTO (fluorine-doped tin oxide, F-SnO 2 ), wash with deionized water 5 times to remove impurities by means of nanofiltration membrane, transfer the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com